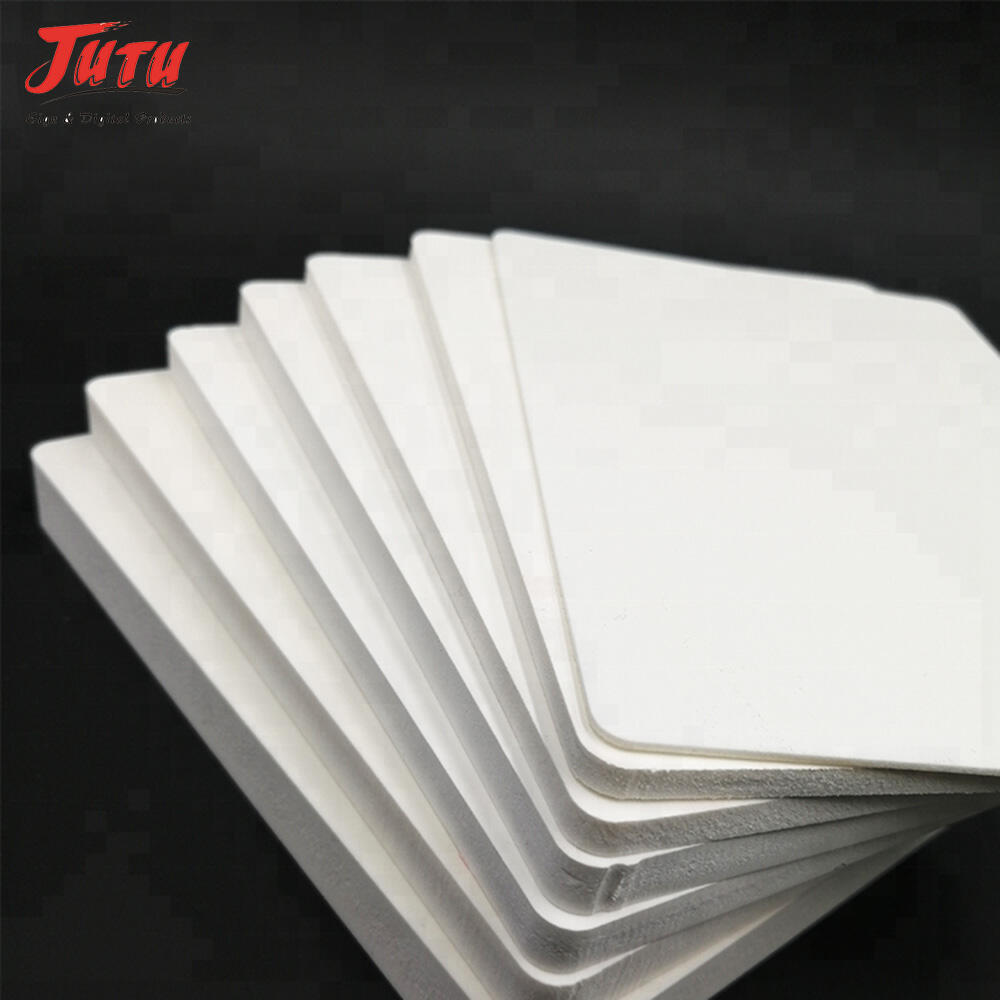

pvc foam board for advertising

PVC foam board for advertising represents a revolutionary advancement in modern display materials, combining exceptional durability with outstanding visual appeal. This lightweight yet robust material consists of expanded polyvinyl chloride cells that create a uniform foam structure, delivering superior performance across diverse advertising applications. The manufacturing process involves precision extrusion techniques that produce smooth, consistent surfaces ideal for high-quality graphics and text reproduction. PVC foam board for advertising offers remarkable versatility, serving as the backbone for indoor and outdoor signage solutions. The material's closed-cell structure provides excellent moisture resistance, making it suitable for challenging environmental conditions. Temperature stability remains consistent across varying climates, ensuring long-term performance reliability. The smooth surface texture accepts various printing methods, including digital printing, screen printing, and vinyl application with exceptional adhesion properties. Cutting and fabrication processes prove remarkably straightforward, allowing for precise customization without specialized equipment requirements. The material's dimensional stability prevents warping, bowing, or distortion under normal usage conditions. Chemical resistance properties protect against common cleaning agents and environmental pollutants, maintaining pristine appearance over extended periods. PVC foam board for advertising demonstrates superior impact resistance compared to traditional materials like cardboard or standard plastic sheets. The uniform cell structure distributes stress evenly, preventing crack propagation and structural failure. Flame retardant properties enhance safety compliance for indoor installations, meeting strict building codes and safety regulations. Color consistency throughout the material thickness ensures clean edge finishing without unsightly core exposure. The material's low density reduces shipping costs while maintaining structural integrity. Installation procedures require minimal specialized knowledge, enabling efficient deployment across various mounting systems. Weather resistance capabilities extend service life significantly beyond conventional advertising materials, providing exceptional return on investment for commercial applications.