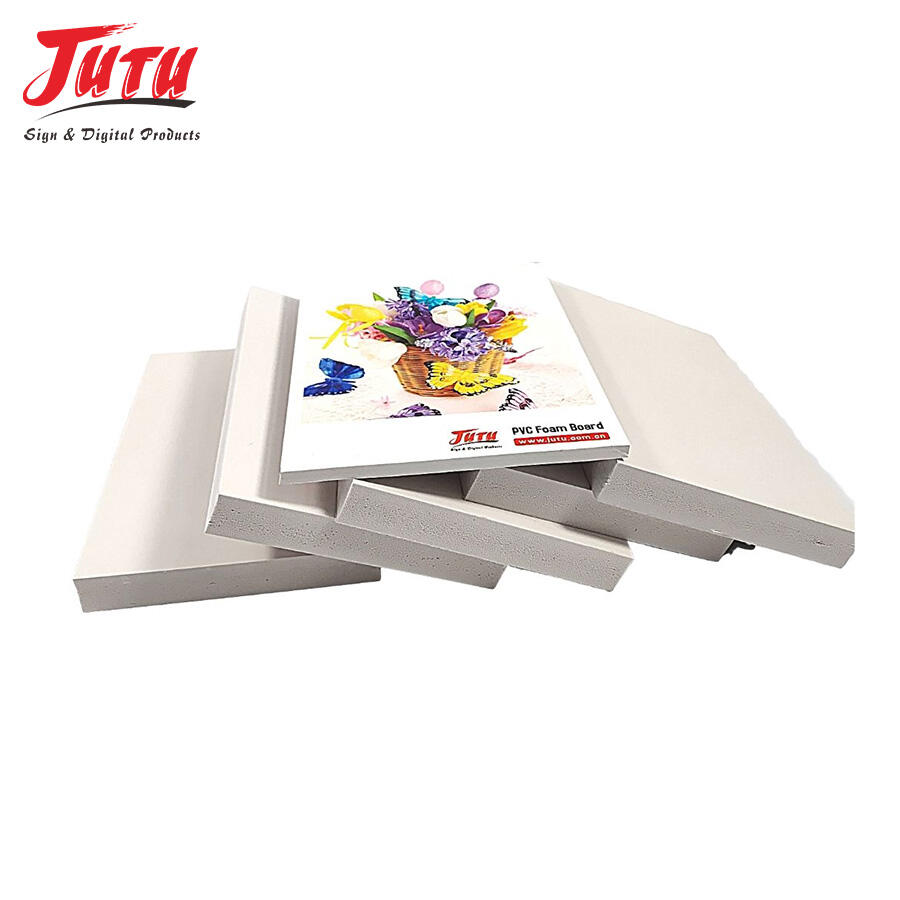

pvc foam board sizes

PVC foam board sizes represent a comprehensive range of lightweight, versatile building materials that have revolutionized modern construction and fabrication industries. These boards are manufactured in various standardized dimensions to meet diverse project requirements, typically ranging from small format sheets measuring 1220mm x 610mm to large industrial panels extending up to 3050mm x 2030mm. The thickness variations span from ultra-thin 1mm sheets to robust 30mm panels, providing exceptional flexibility for different structural and aesthetic applications. The main function of PVC foam board sizes lies in their ability to serve as cost-effective substitutes for traditional materials like wood, metal, and concrete in numerous applications. These boards excel in providing excellent insulation properties, moisture resistance, and chemical stability while maintaining structural integrity across temperature fluctuations. Technologically, PVC foam boards feature a closed-cell foam structure that delivers superior strength-to-weight ratios, making them ideal for applications requiring both durability and portability. The manufacturing process involves precise extrusion techniques that ensure consistent density distribution and uniform surface finish across all available sizes. This technological advancement enables manufacturers to produce boards with exceptional dimensional stability and minimal warping tendencies. Applications for PVC foam board sizes span across multiple sectors including construction, advertising, marine industries, furniture manufacturing, and architectural design. In construction, these boards serve as wall cladding, ceiling panels, and partition systems. The advertising industry utilizes various sizes for creating durable outdoor signage, exhibition displays, and promotional materials. Marine applications benefit from the boards' excellent water resistance properties, while furniture manufacturers appreciate the ease of fabrication and finishing options available across different size specifications.