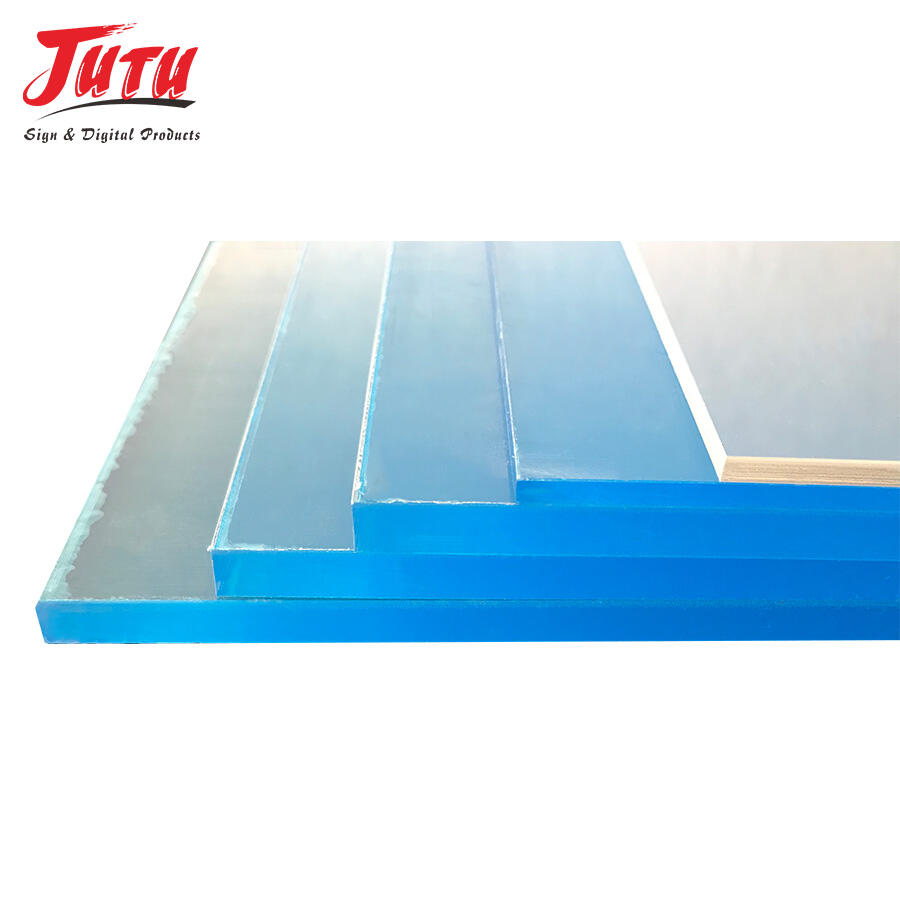

frosted acrylic perspex sheet manufacturer

A frosted acrylic perspex sheet manufacturer represents a specialized industrial entity that produces high-quality translucent plastic materials through advanced polymer processing techniques. These manufacturers focus on creating sheets that combine the clarity and durability of traditional acrylic with a distinctive frosted finish that diffuses light while maintaining structural integrity. The primary function of these manufacturers involves converting raw acrylic polymers into finished sheets through processes including casting, extrusion, and surface texturing. The frosted acrylic perspex sheet manufacturer employs sophisticated machinery and quality control systems to ensure consistent thickness, optical properties, and surface finish across all products. Technological features include precision temperature control during production, automated cutting systems, and specialized etching processes that create the characteristic frosted appearance. The manufacturing process involves melting acrylic pellets, forming them into sheets, and applying surface treatments that create microscopic textures for light diffusion. These manufacturers serve diverse applications including architectural glazing, retail displays, office partitions, decorative panels, and lighting fixtures. In commercial construction, frosted acrylic sheets provide privacy while allowing natural light transmission. Retail environments utilize these materials for product displays, signage, and store fixtures. The automotive industry incorporates frosted acrylic sheets for interior components and light covers. Medical facilities benefit from these materials in equipment housings and privacy screens. Educational institutions use frosted acrylic sheets for whiteboards, display cases, and room dividers. The frosted acrylic perspex sheet manufacturer must maintain strict quality standards to meet building codes and safety regulations. Advanced testing equipment verifies optical clarity, impact resistance, and weather durability. Modern manufacturers also focus on sustainability by implementing recycling programs and reducing waste during production. These companies typically offer customization services including specific dimensions, thickness variations, and color tinting to meet unique project requirements.