acrylic large sheets manufacturer

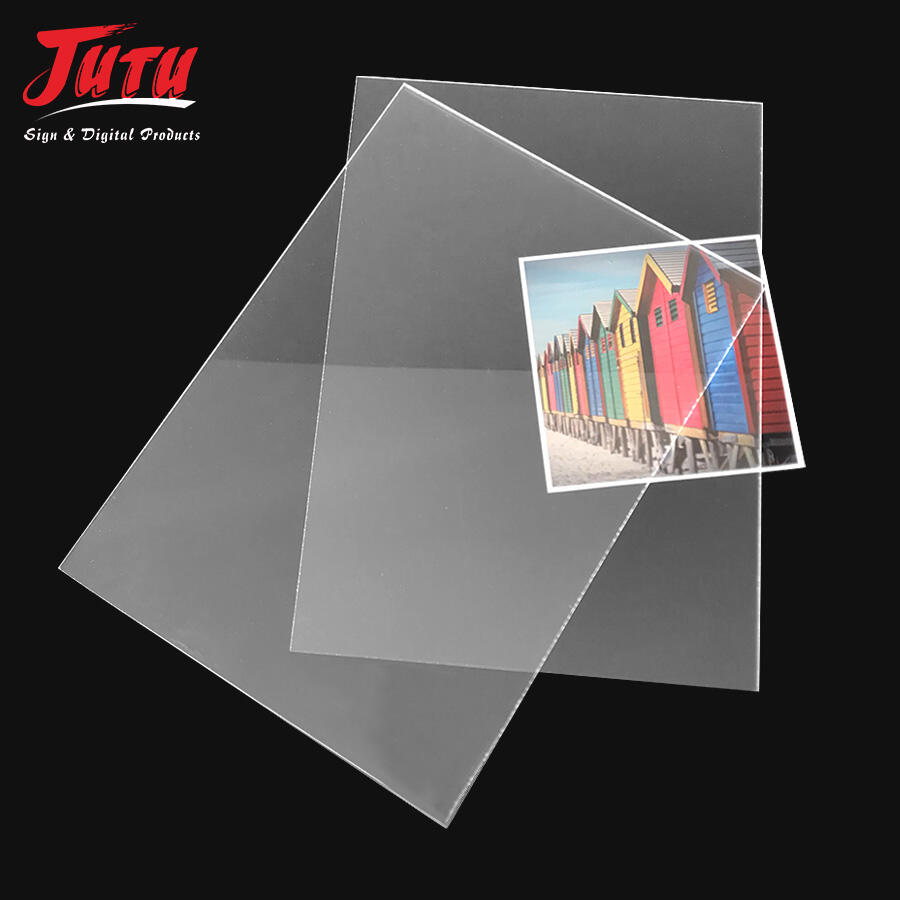

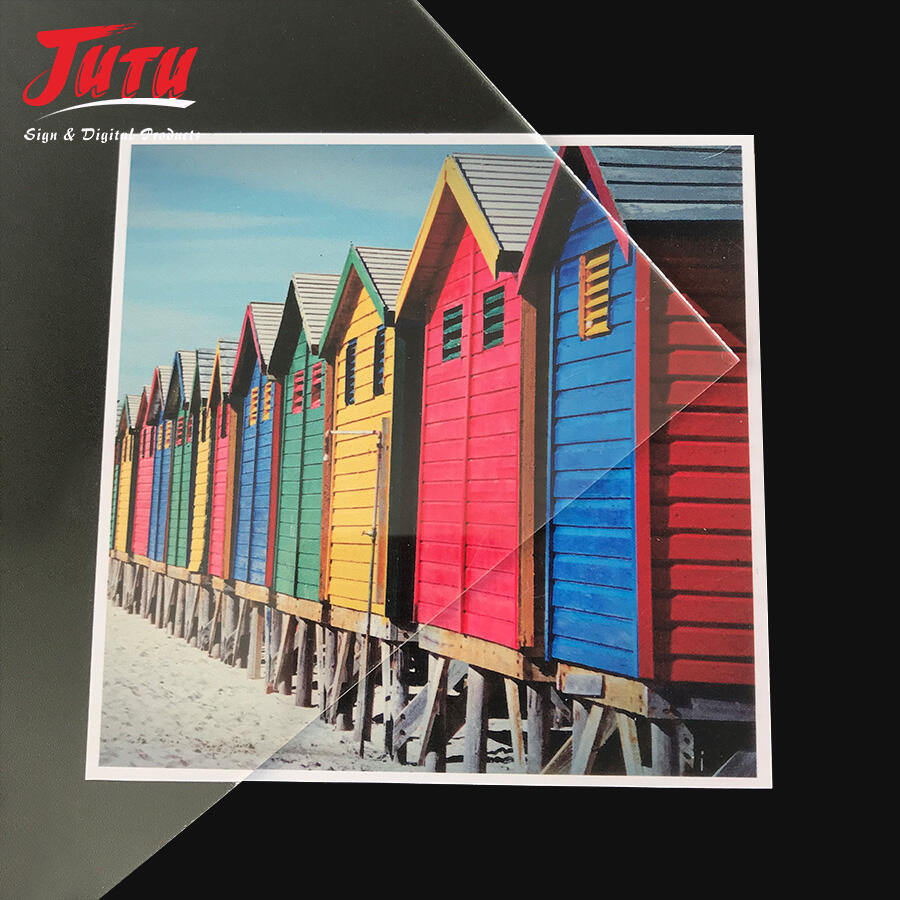

An acrylic large sheets manufacturer represents a specialized industrial facility dedicated to producing high-quality polymethyl methacrylate (PMMA) panels in expansive dimensions. These manufacturing operations combine advanced polymer chemistry with precision engineering to create transparent, durable sheets that serve diverse commercial and industrial applications. The primary function of an acrylic large sheets manufacturer involves transforming raw acrylic resins through sophisticated polymerization processes, resulting in crystal-clear panels that maintain exceptional optical clarity and structural integrity. Modern acrylic large sheets manufacturer facilities utilize state-of-the-art extrusion and casting technologies to produce sheets ranging from standard commercial sizes to custom oversized panels exceeding 10 feet in length and width. The technological backbone of any reputable acrylic large sheets manufacturer includes computer-controlled production lines that ensure consistent thickness tolerances, superior surface finish quality, and minimal internal stress patterns. These manufacturers employ advanced quality control systems incorporating laser measurement devices, optical clarity testing equipment, and stress analysis tools to guarantee each sheet meets stringent industry standards. Temperature-controlled production environments maintained by professional acrylic large sheets manufacturer operations ensure optimal curing conditions and prevent thermal expansion issues during the manufacturing process. The applications for products from an acrylic large sheets manufacturer span multiple industries including architectural glazing, retail display systems, aquarium construction, signage fabrication, and protective barrier installations. Modern acrylic large sheets manufacturer facilities often provide additional services such as precision cutting, edge polishing, drilling, and custom fabrication to meet specific customer requirements while maintaining the material's inherent properties of impact resistance, UV stability, and weather durability.