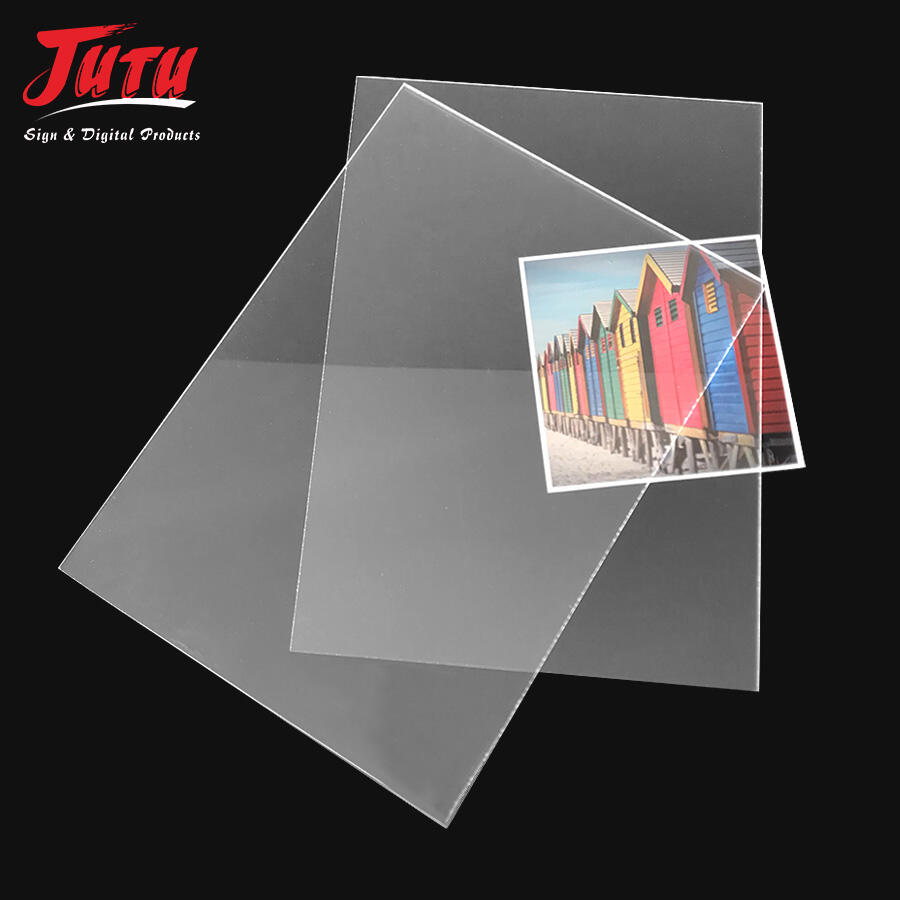

custom acrylic sheets manufacturer

A custom acrylic sheets manufacturer specializes in producing tailored acrylic panels that meet specific client requirements across diverse industries. These manufacturers utilize advanced production technologies to create high-quality acrylic sheets with precise dimensions, colors, textures, and properties. The main functions include cutting, shaping, drilling, engraving, and finishing acrylic materials to exact specifications. Custom acrylic sheets manufacturers employ sophisticated machinery such as CNC routers, laser cutting systems, and precision molding equipment to achieve exceptional accuracy and consistency in their products. The technological features encompass computer-aided design integration, automated production lines, and quality control systems that ensure each sheet meets stringent standards. These manufacturers work with various acrylic formulations including clear, colored, textured, and specialty grades that offer different optical, mechanical, and chemical properties. Applications span numerous sectors including architectural glazing, retail displays, signage, medical devices, automotive components, and industrial equipment. The manufacturing process begins with material selection, followed by precision cutting or molding, surface treatments, and final quality inspection. Advanced custom acrylic sheets manufacturers maintain strict environmental controls during production to prevent contamination and ensure optimal clarity. They also offer additional services such as protective film application, custom packaging, and logistics support. The ability to produce both small prototype quantities and large-scale production runs makes these manufacturers valuable partners for businesses ranging from startups to multinational corporations. Quality certifications and compliance with industry standards demonstrate their commitment to excellence and reliability in serving diverse market segments.