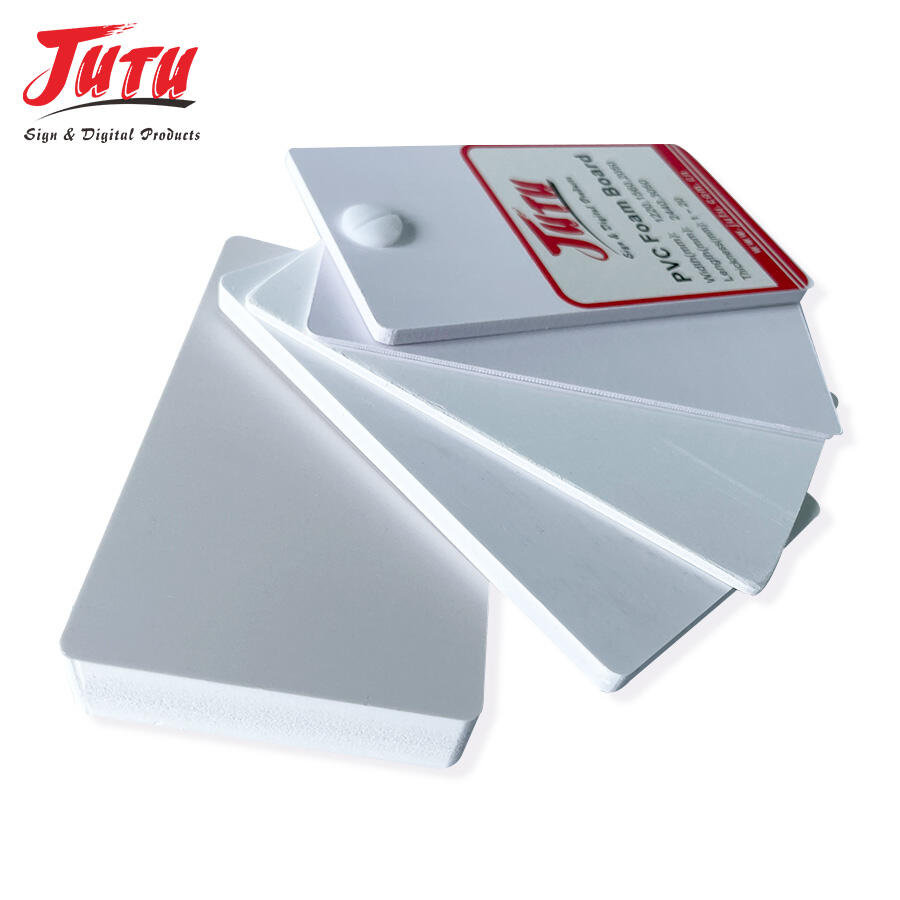

Exceptional Workability and Fabrication Flexibility

The exceptional workability of expanded PVC foam board provides fabricators and installers with unmatched flexibility in creating custom solutions for complex design requirements. This superior workability begins with the material's ability to be cut, shaped, and machined using standard woodworking tools, eliminating the need for specialized equipment investments or extensive worker training programs. The consistent density and cellular structure of expanded PVC foam board ensures clean, precise cuts without the chipping, tearing, or splintering that commonly occurs with other foam materials or composite products. Routing operations produce smooth, professional-looking edges and decorative profiles that enhance the aesthetic appeal of finished projects while maintaining the structural integrity of the expanded PVC foam board. The material readily accepts various fastening methods, including screws, nails, staples, and adhesives, providing installation flexibility that accommodates different construction techniques and project requirements. Thermoforming capabilities of expanded PVC foam board allow fabricators to create complex curved shapes and three-dimensional forms that would be impossible or prohibitively expensive using traditional rigid materials. Heat welding techniques can permanently join expanded PVC foam board sections, creating seamless assemblies with structural continuity that eliminates potential failure points at joints or connections. The surface preparation requirements for expanded PVC foam board are minimal, as the material accepts primers, paints, and coatings directly without extensive cleaning or chemical etching procedures. Digital printing technologies can apply graphics directly onto expanded PVC foam board surfaces, enabling custom signage and decorative applications with vibrant colors and sharp detail reproduction. Lamination processes can bond various materials to expanded PVC foam board surfaces, creating hybrid products that combine the lightweight properties of the foam core with specialized surface characteristics such as high gloss, texture, or specific chemical resistance.