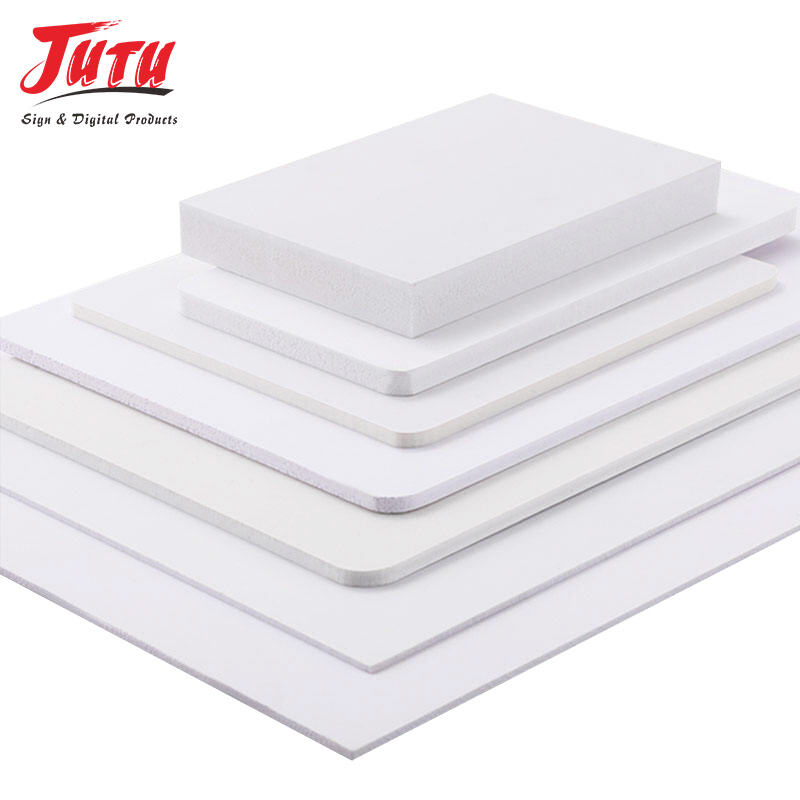

expanded foam pvc board

Expanded foam PVC board represents a revolutionary building material that combines lightweight construction with exceptional durability and versatility. This cellular PVC material features a unique closed-cell foam structure that delivers outstanding performance across multiple industries and applications. The expanded foam PVC board manufacturing process involves expanding PVC resin through controlled heating and chemical foaming agents, creating a uniform cellular structure that maintains structural integrity while significantly reducing weight compared to solid materials. The technological innovation behind expanded foam PVC board lies in its advanced polymer chemistry, which creates millions of microscopic air pockets throughout the material matrix. This cellular architecture provides exceptional insulation properties, making expanded foam PVC board an ideal choice for thermal management applications. The board exhibits remarkable resistance to moisture, chemicals, and environmental factors that typically degrade conventional materials. Its non-porous surface prevents water absorption, eliminating concerns about rot, decay, or dimensional instability that plague traditional wood-based products. The expanded foam PVC board maintains consistent performance across extreme temperature ranges, from freezing conditions to high-heat environments. Manufacturing precision ensures uniform density distribution throughout each expanded foam PVC board panel, guaranteeing predictable mechanical properties and reliable performance. The material accepts various surface treatments, including painting, printing, laminating, and texturing, enabling customization for specific aesthetic requirements. Processing capabilities include cutting, drilling, routing, welding, and thermoforming, making expanded foam PVC board adaptable to complex fabrication demands. Applications span construction, signage, marine, automotive, furniture, and industrial sectors where lightweight yet robust materials are essential. The expanded foam PVC board delivers consistent quality, dimensional stability, and long-term performance that exceeds traditional alternatives while offering cost-effective solutions for demanding applications.