Versatile Processing Capabilities That Reduce Project Complexity

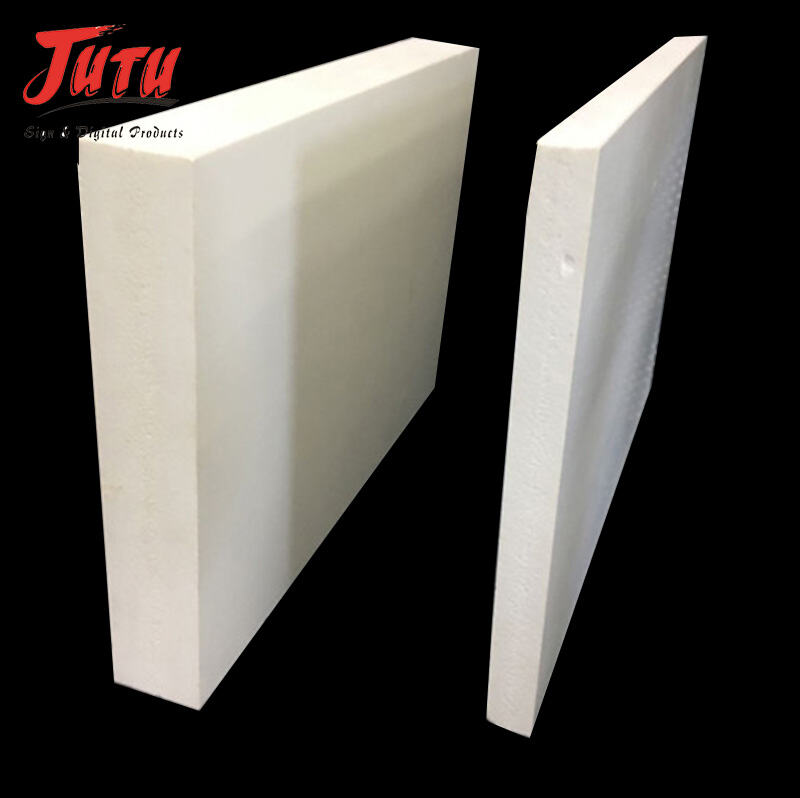

The processing versatility inherent in PVC foam boards makes the PVC foam board price exceptionally attractive by simplifying project execution and reducing complexity across diverse applications. This adaptability stems from the material's engineered properties that accept multiple fabrication methods, finishing techniques, and installation approaches using standard tools and equipment. The PVC foam board price includes access to a material that cuts cleanly with conventional saws, routers, or knife blades without specialized equipment investments, making projects accessible to users with basic workshop capabilities. Drilling and fastening operations proceed smoothly without cracking or splitting, allowing secure installations using screws, bolts, or adhesives without pre-drilling requirements that add time and complexity. Surface preparation needs remain minimal, as the smooth finish accepts paint, vinyl graphics, or laminated materials directly without sanding, priming, or chemical treatments that increase project costs and timelines. Heat forming capabilities allow three-dimensional shaping for curved installations or custom profiles, expanding design possibilities without requiring expensive molding or forming equipment. The uniform density throughout the foam core ensures consistent machining results, eliminating material waste from unpredictable cutting behavior or surface imperfections. Digital printing compatibility opens creative opportunities for custom graphics, signage, or decorative elements that integrate seamlessly with the base material properties. Welding and bonding techniques create permanent joints for complex assemblies, while mechanical fastening allows removable connections for maintenance or reconfiguration needs. Edge finishing options include routing, beveling, or laminating techniques that create professional appearances without specialized skills or tools. The chemical compatibility with common adhesives, sealants, and coatings simplifies material integration in multi-component assemblies or systems. These processing advantages reduce project planning complexity by eliminating concerns about tool availability, skill requirements, or specialized techniques that could increase costs or delay completion. The PVC foam board price thus represents access to manufacturing flexibility that adapts to project requirements rather than forcing design compromises based on material limitations.