chawla pvc foam board

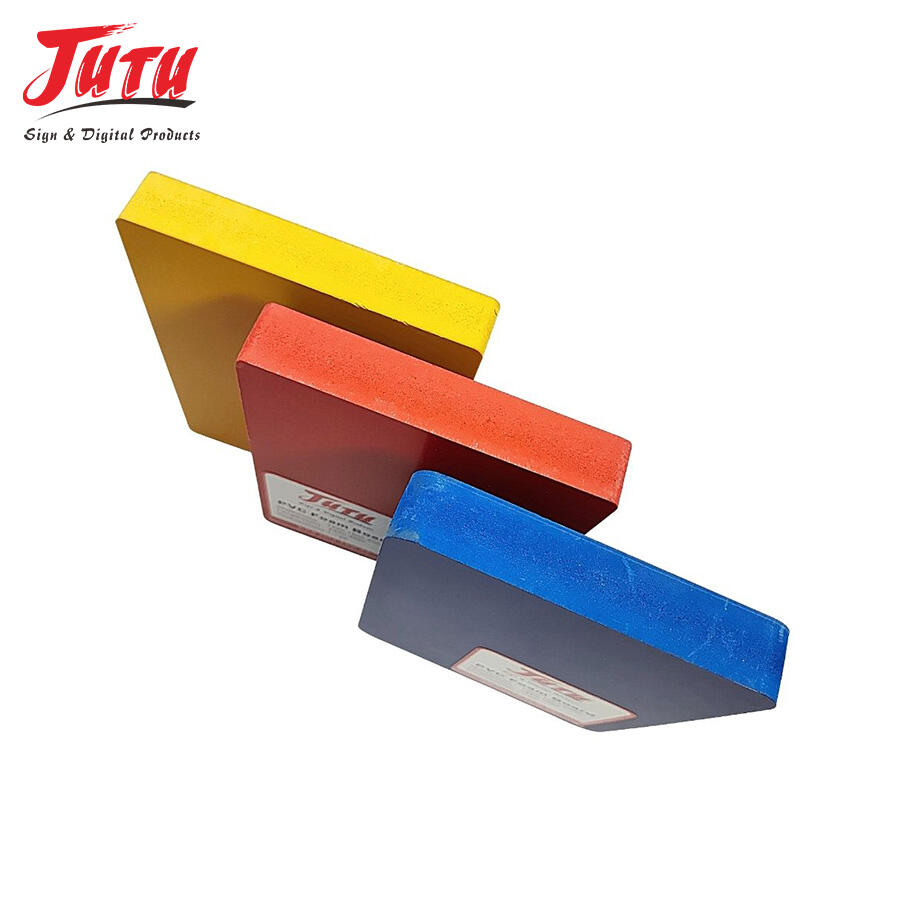

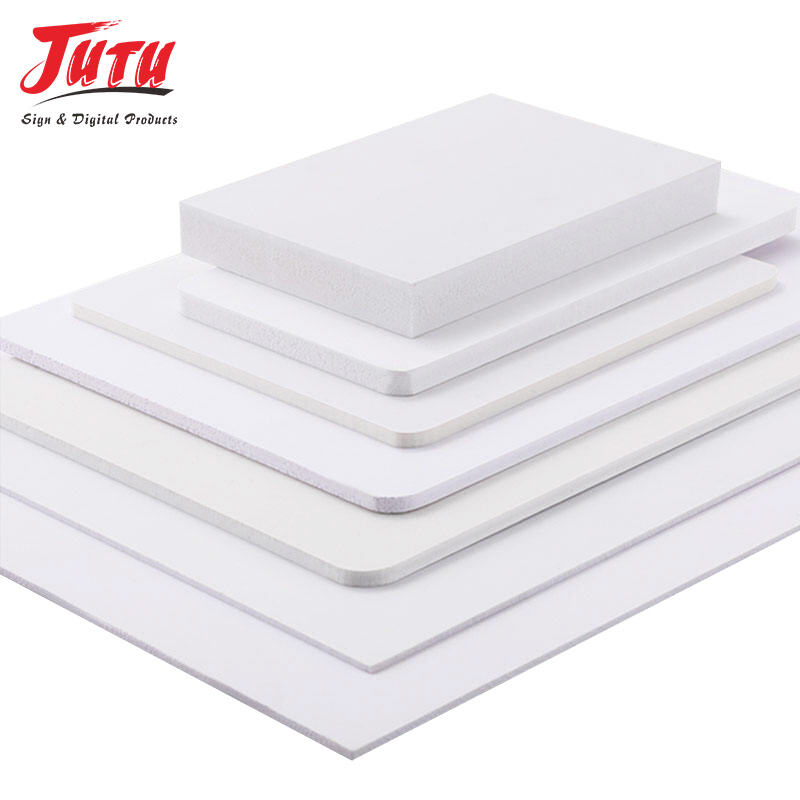

The Chawla PVC foam board represents a revolutionary advancement in modern construction and signage materials, combining superior quality with exceptional versatility. This innovative product features a closed-cell foam core structure sandwiched between smooth PVC surfaces, creating a lightweight yet remarkably durable material solution. The Chawla PVC foam board utilizes advanced extrusion technology to achieve consistent density throughout its structure, ensuring reliable performance across various applications. Its main functions encompass interior and exterior signage, architectural cladding, furniture construction, and decorative paneling. The technological features of this Chawla PVC foam board include excellent chemical resistance, superior weatherability, and outstanding dimensional stability under varying temperature conditions. The material maintains its structural integrity across temperature ranges from -20°C to 60°C, making it suitable for diverse climatic conditions. The Chawla PVC foam board offers exceptional machinability, allowing for easy cutting, drilling, routing, and shaping using standard woodworking tools. Its uniform cellular structure prevents chipping and cracking during fabrication processes. The board exhibits excellent printability and paint adhesion properties, accepting various printing methods including screen printing, digital printing, and vinyl application. The Chawla PVC foam board finds extensive applications in retail displays, exhibition stands, outdoor advertising, kitchen cabinets, bathroom fixtures, and marine environments. Its moisture resistance makes it particularly valuable in high-humidity applications where traditional materials might fail. The board's flame-retardant properties meet international safety standards, providing additional security in commercial installations. The smooth surface finish eliminates the need for extensive preparation before painting or laminating, reducing installation time and costs. Environmental considerations have been integrated into the manufacturing process, with the Chawla PVC foam board being 100% recyclable and containing no harmful substances like formaldehyde or heavy metals.