buy aluminum composite panel

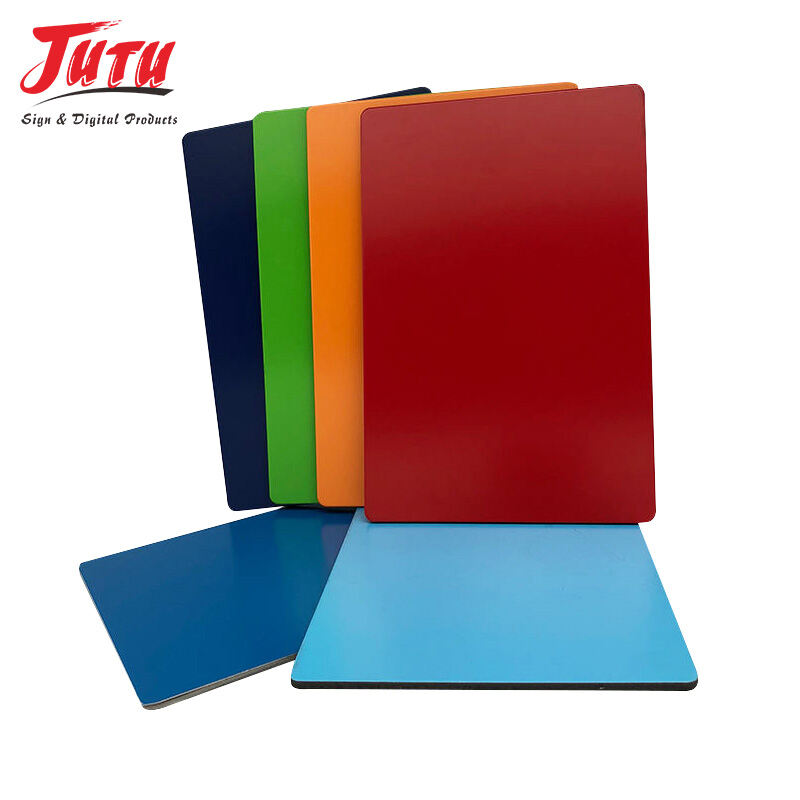

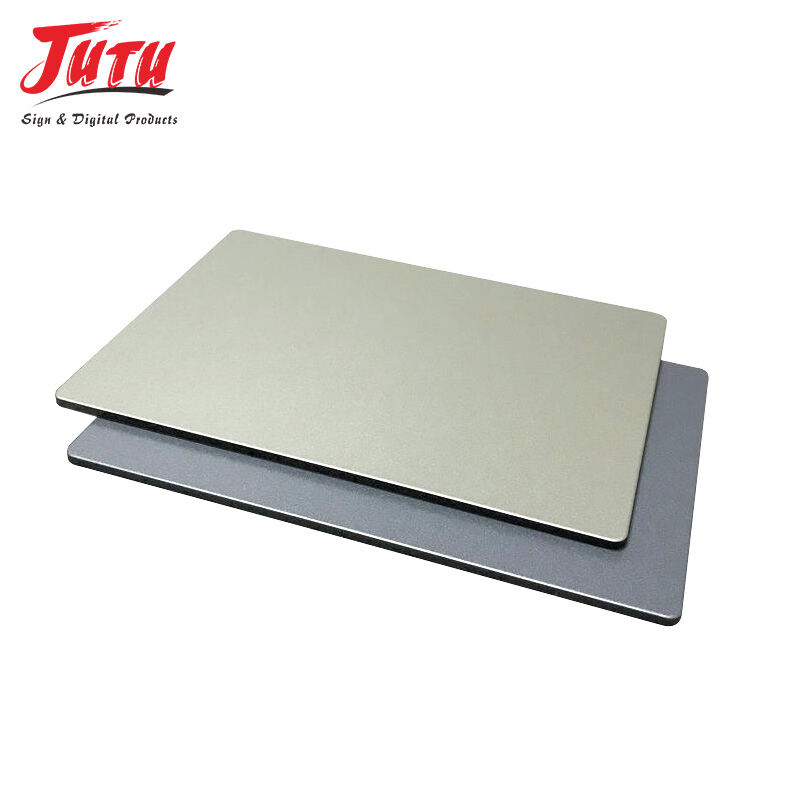

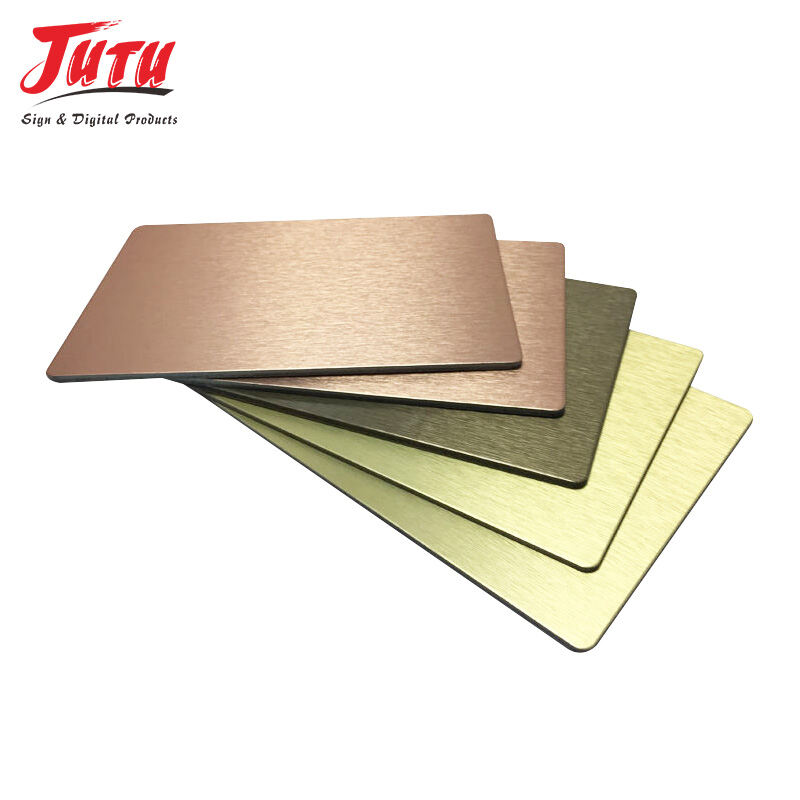

When you buy aluminum composite panel, you invest in one of the most versatile and innovative building materials available in today's construction industry. An aluminum composite panel consists of two thin aluminum sheets bonded to a non-aluminum core, typically made from polyethylene or fire-retardant mineral materials. This three-layer sandwich construction creates a lightweight yet incredibly strong panel that offers exceptional performance across multiple applications. The main functions of aluminum composite panels include providing weather protection, thermal insulation, sound dampening, and aesthetic enhancement to building facades and interior surfaces. These panels serve as excellent cladding materials that protect structures from environmental elements while maintaining visual appeal. The technological features that make aluminum composite panels superior include advanced bonding techniques that ensure permanent adhesion between layers, precision manufacturing processes that guarantee consistent thickness and flatness, and sophisticated coating technologies that provide long-lasting color retention and surface protection. Modern production methods incorporate computer-controlled cutting and shaping capabilities, allowing for complex architectural designs and custom configurations. The core material options range from standard polyethylene for general applications to fire-resistant mineral cores for enhanced safety requirements. Surface treatments include PVDF coatings for maximum durability, polyester finishes for cost-effective solutions, and specialized textures that mimic natural materials like wood or stone. Applications for aluminum composite panels span commercial architecture, residential construction, transportation infrastructure, and signage industries. These panels excel in curtain wall systems, building facades, interior partitions, ceiling applications, and decorative elements. Their lightweight nature reduces structural load requirements while their dimensional stability ensures long-term performance without warping or sagging. The panels resist corrosion, UV radiation, and thermal expansion, making them ideal for both interior and exterior applications in diverse climatic conditions.