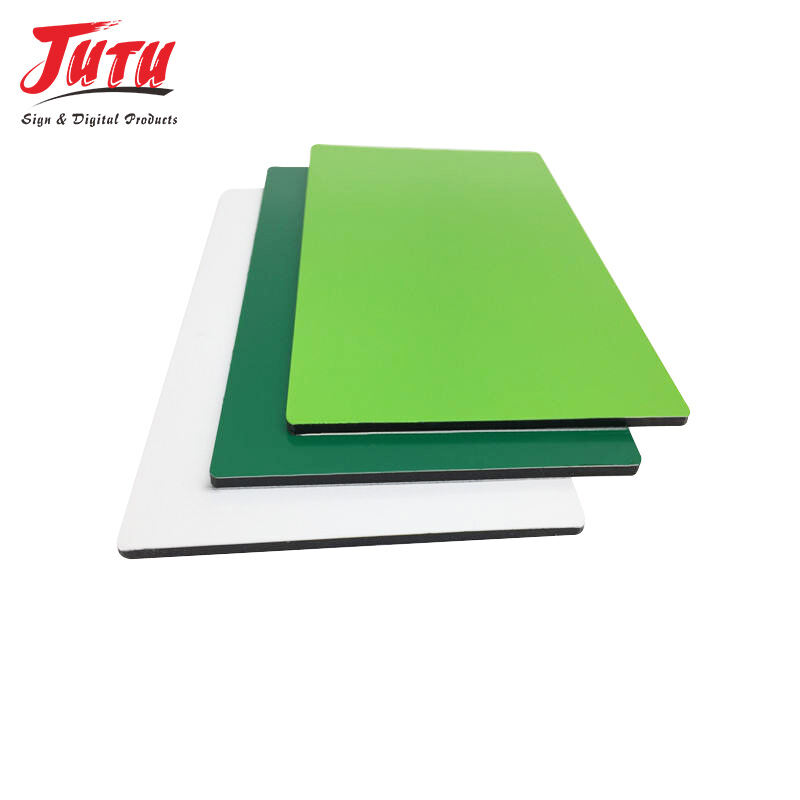

aluminium composite cladding

Aluminium composite cladding represents a revolutionary building material that combines functionality with aesthetic appeal, transforming modern architecture worldwide. This innovative cladding system consists of two thin aluminium sheets bonded to a lightweight core material, typically polyethylene or mineral-filled core, creating a sandwich panel structure that delivers exceptional performance characteristics. The primary functions of aluminium composite cladding include weather protection, thermal insulation, sound dampening, and architectural enhancement for both commercial and residential buildings. The technological features of this advanced cladding system incorporate precision-engineered bonding processes that ensure long-lasting adhesion between layers, while specialized coatings provide superior resistance to UV radiation, corrosion, and environmental degradation. The aluminium composite cladding manufacturing process utilizes continuous lamination technology, which guarantees consistent quality and dimensional stability across large panel surfaces. Modern production techniques enable the creation of panels with various surface finishes, including brushed, mirror, wood grain, stone texture, and vibrant color options through advanced coating technologies like PVDF and polyester finishes. Applications for aluminium composite cladding span diverse construction projects, from high-rise office buildings and shopping centers to residential facades and interior wall systems. The versatility of aluminium composite cladding makes it suitable for curtain wall systems, column covers, canopies, signage applications, and renovation projects where lightweight yet durable materials are essential. Architects and designers frequently specify aluminium composite cladding for projects requiring complex geometric shapes, curved surfaces, and intricate design details due to its excellent formability and workability characteristics. The material's compatibility with standard construction methods and tools facilitates efficient installation processes, reducing project timelines and labor costs while maintaining superior finished quality.