aluminum composite panel siding

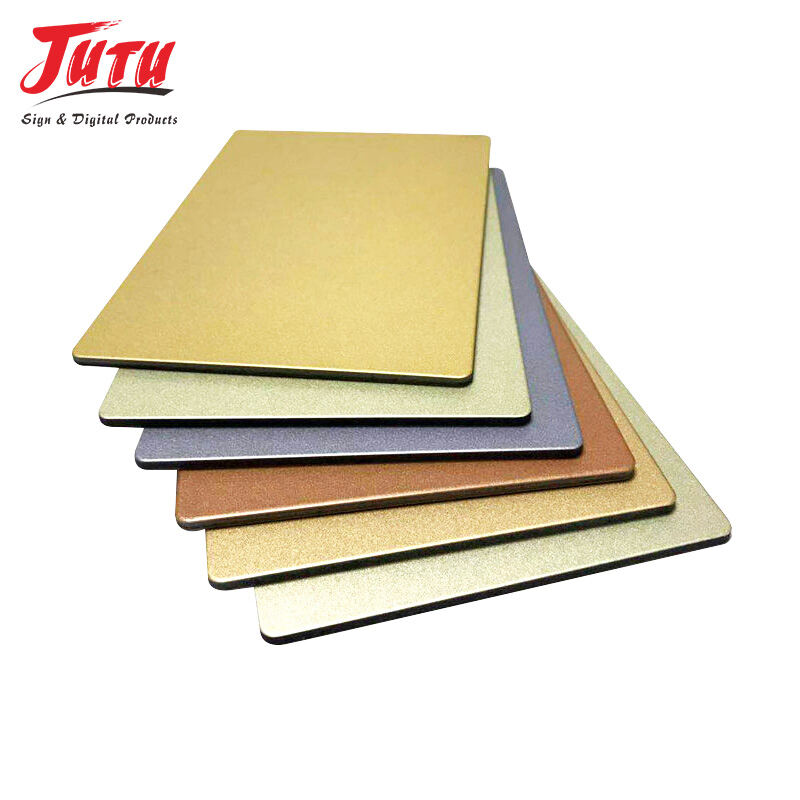

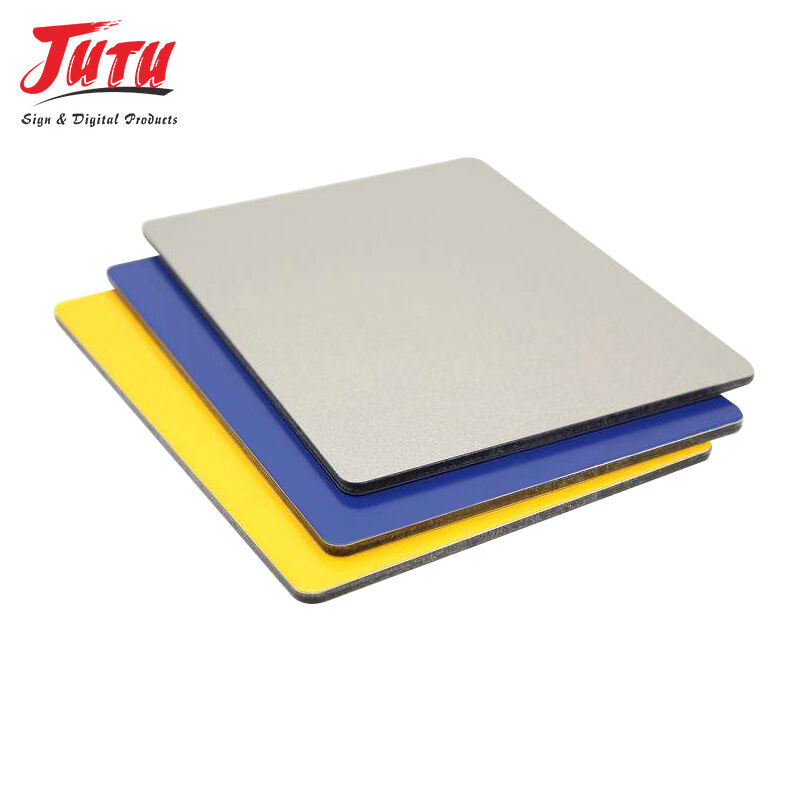

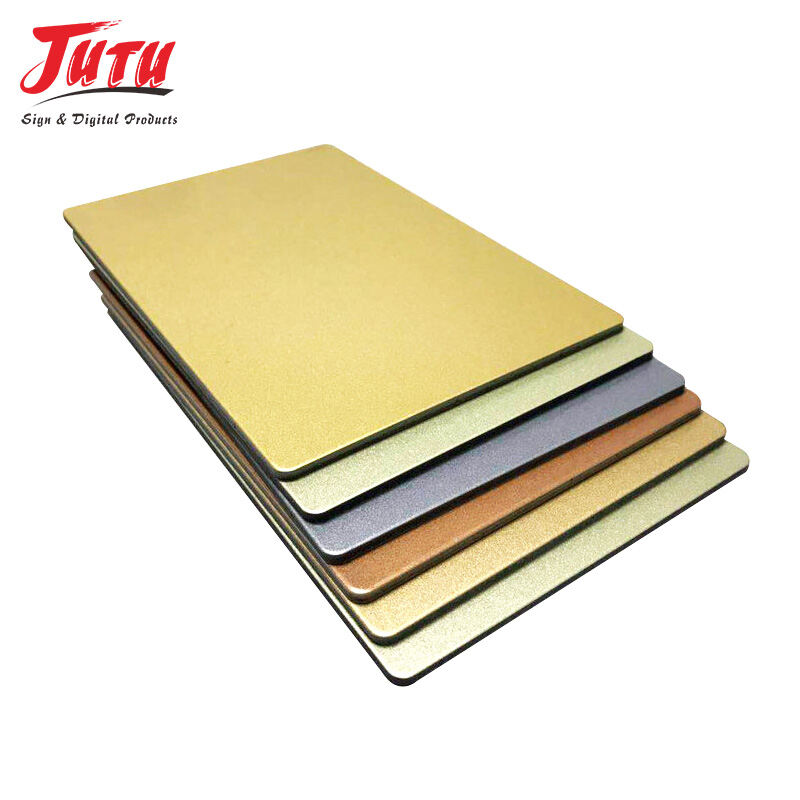

Aluminum composite panel siding represents a revolutionary building material that combines cutting-edge technology with practical functionality for modern construction projects. This innovative siding solution consists of two aluminum sheets bonded to a polyethylene core, creating a lightweight yet robust exterior cladding system. The aluminum composite panel siding delivers exceptional performance through its unique three-layer construction, where thin aluminum faces provide strength and weather resistance while the polymer core offers insulation properties and dimensional stability. This architectural marvel serves multiple functions including weather protection, thermal insulation, and aesthetic enhancement for residential, commercial, and industrial buildings. The technological features of aluminum composite panel siding include advanced coating systems that resist fading, chalking, and corrosion, ensuring long-lasting color retention and surface integrity. Manufacturing processes involve precision bonding techniques that create seamless integration between layers, resulting in panels that maintain structural integrity under various environmental conditions. The siding system incorporates fire-retardant properties through specialized core materials and surface treatments, meeting stringent building codes and safety requirements. Applications for aluminum composite panel siding span diverse sectors, from high-rise office buildings and shopping centers to residential facades and renovation projects. The versatility of this material allows architects and designers to create striking visual effects while maintaining functional performance. Installation flexibility makes aluminum composite panel siding suitable for both new construction and retrofit applications, adapting to various substrate conditions and architectural requirements. The panels can be fabricated into custom shapes and sizes, accommodating complex design geometries and creative architectural visions. This adaptability, combined with superior durability and low maintenance requirements, positions aluminum composite panel siding as a preferred choice for contemporary building projects seeking both aesthetic appeal and long-term performance reliability.