aluwell aluminium composite panel

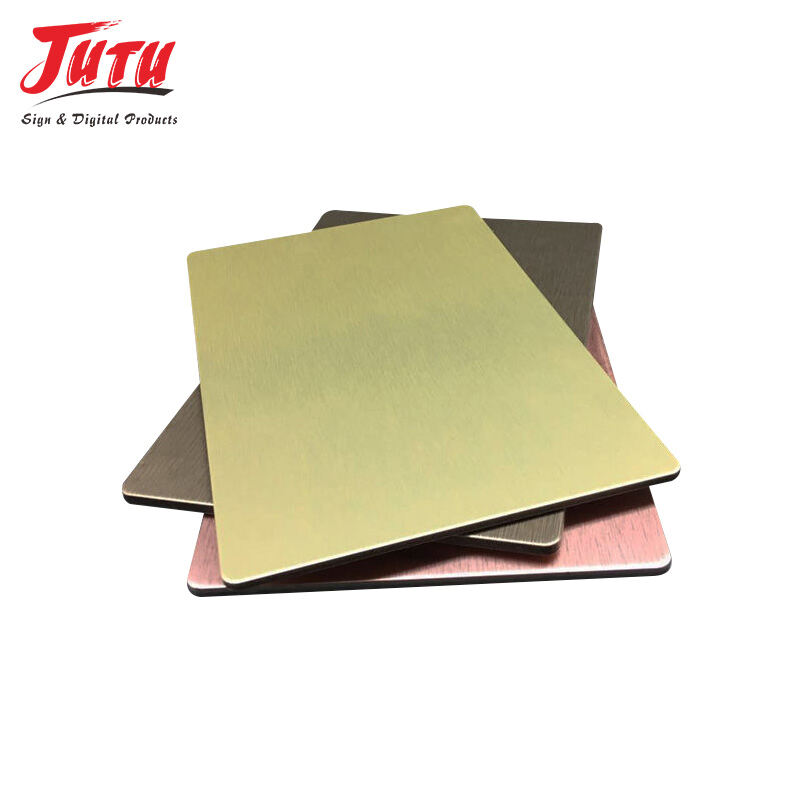

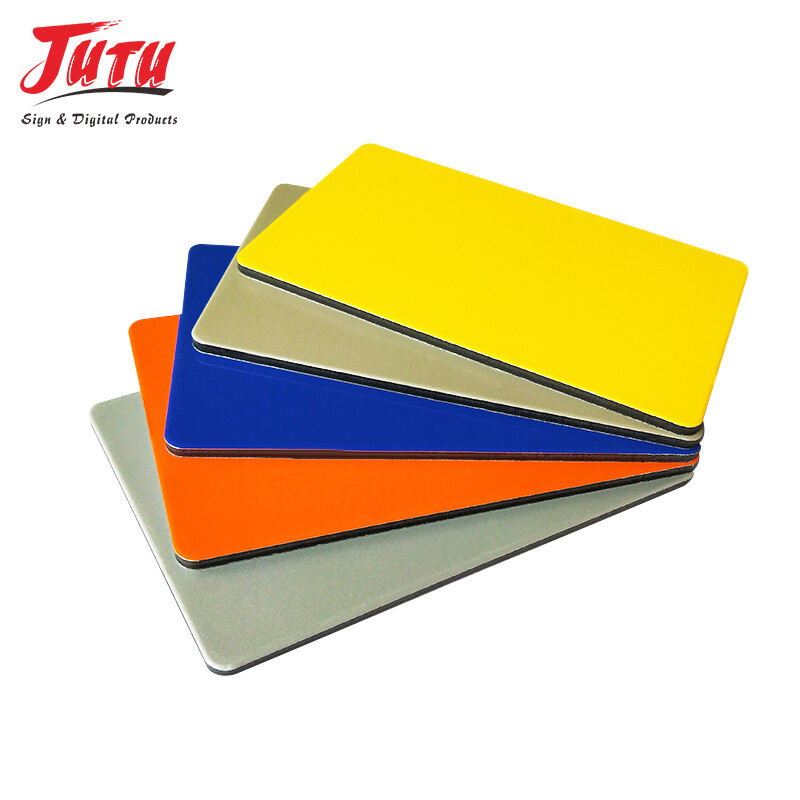

The aluwell aluminium composite panel represents a cutting-edge building material that combines superior performance with architectural versatility. This innovative composite panel consists of two thin aluminum sheets bonded to a non-aluminum core, creating a lightweight yet remarkably strong construction material. The aluwell aluminium composite panel delivers exceptional structural integrity while maintaining optimal weight characteristics that facilitate easier installation and reduced building loads. Modern manufacturing processes ensure that each aluwell aluminium composite panel meets stringent quality standards for dimensional stability and surface uniformity. The panel's core material varies depending on specific applications, with options including polyethylene, mineral-filled cores, and fire-retardant compositions. This flexibility allows the aluwell aluminium composite panel to adapt to diverse project requirements while maintaining consistent performance standards. The surface treatment of the aluwell aluminium composite panel incorporates advanced coating technologies that provide long-lasting color retention and weather resistance. These panels excel in both interior and exterior applications, offering architects and designers unprecedented creative freedom. The aluwell aluminium composite panel features a smooth, flat surface that accepts various finishing techniques, including digital printing, embossing, and specialized textures. Installation systems for the aluwell aluminium composite panel have been refined to ensure secure mounting while accommodating thermal expansion and contraction. The panel's composite structure provides excellent thermal insulation properties, contributing to energy efficiency in building applications. Manufacturing precision ensures that each aluwell aluminium composite panel maintains consistent thickness tolerances and edge straightness, facilitating seamless installations. Quality control measures throughout production guarantee that every aluwell aluminium composite panel meets performance specifications for flatness, adhesion strength, and surface quality, making it a reliable choice for demanding architectural projects.