aluminum composite panel facade

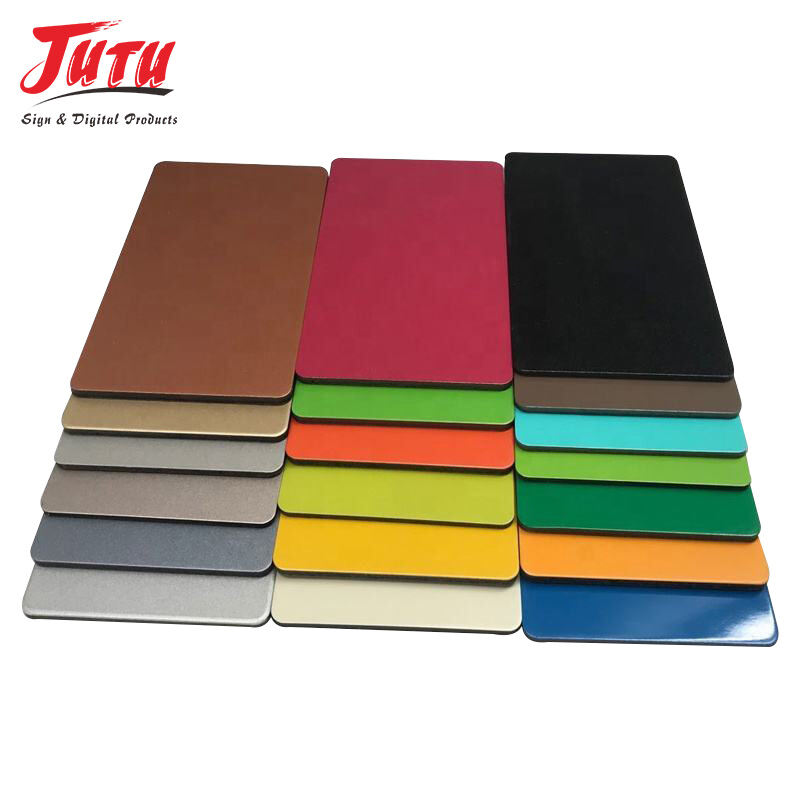

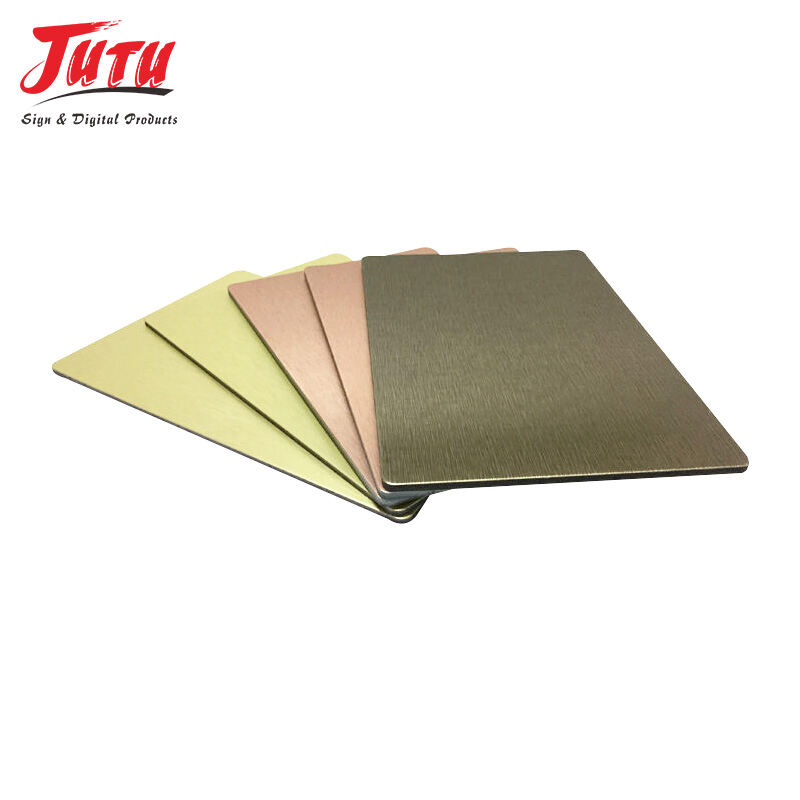

Aluminum composite panel facade systems represent a revolutionary approach to modern building exteriors, combining cutting-edge technology with practical functionality. These innovative cladding solutions consist of two aluminum sheets bonded to a polyethylene core, creating a lightweight yet robust material that transforms architectural design possibilities. The aluminum composite panel facade serves multiple critical functions in contemporary construction, primarily offering superior weather protection while maintaining aesthetic appeal. The technological features of aluminum composite panel facade systems include advanced coating technologies that resist UV radiation, corrosion, and environmental pollutants. These panels utilize state-of-the-art manufacturing processes that ensure consistent quality and dimensional stability across large installations. The core material provides excellent thermal and acoustic insulation properties, contributing to energy-efficient building performance. Installation systems incorporate precision-engineered mounting mechanisms that accommodate thermal expansion and structural movement, ensuring long-term stability. Applications for aluminum composite panel facade extend across diverse building types, from commercial high-rises and retail centers to residential complexes and institutional facilities. Architects and developers choose these systems for their versatility in creating curved surfaces, complex geometries, and seamless integration with other building materials. The aluminum composite panel facade excels in renovation projects, allowing designers to completely transform existing structures without extensive structural modifications. These systems support various finishing options, including solid colors, metallic finishes, wood grain textures, and stone patterns, enabling unlimited creative expression. Manufacturing standards ensure aluminum composite panel facade products meet rigorous fire safety requirements and environmental sustainability criteria. Quality control processes monitor every production stage, from raw material selection to final panel inspection, guaranteeing consistent performance standards that exceed industry expectations.