aluminium composite panel fabrication

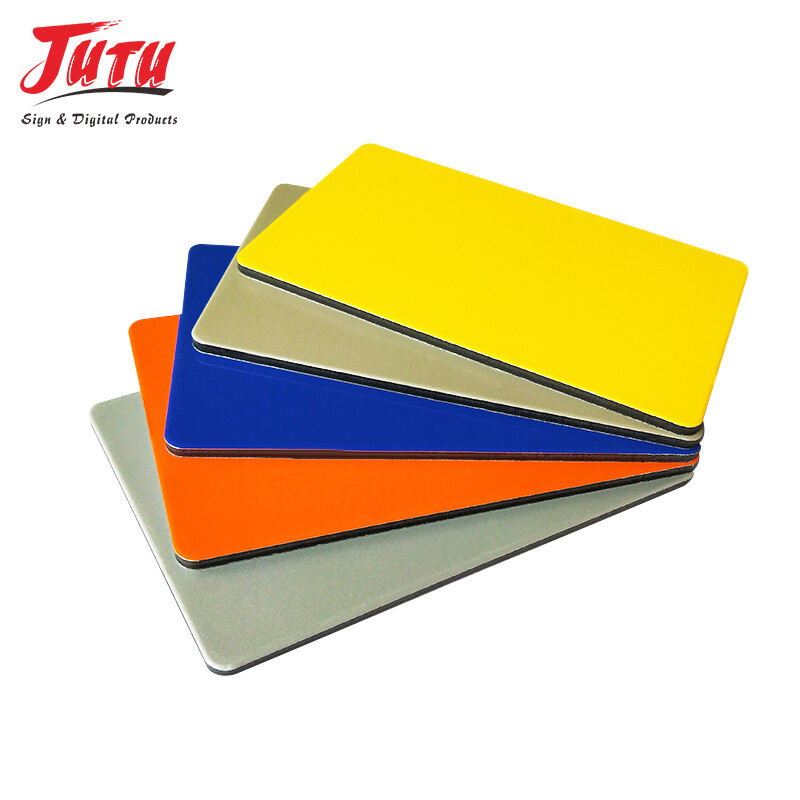

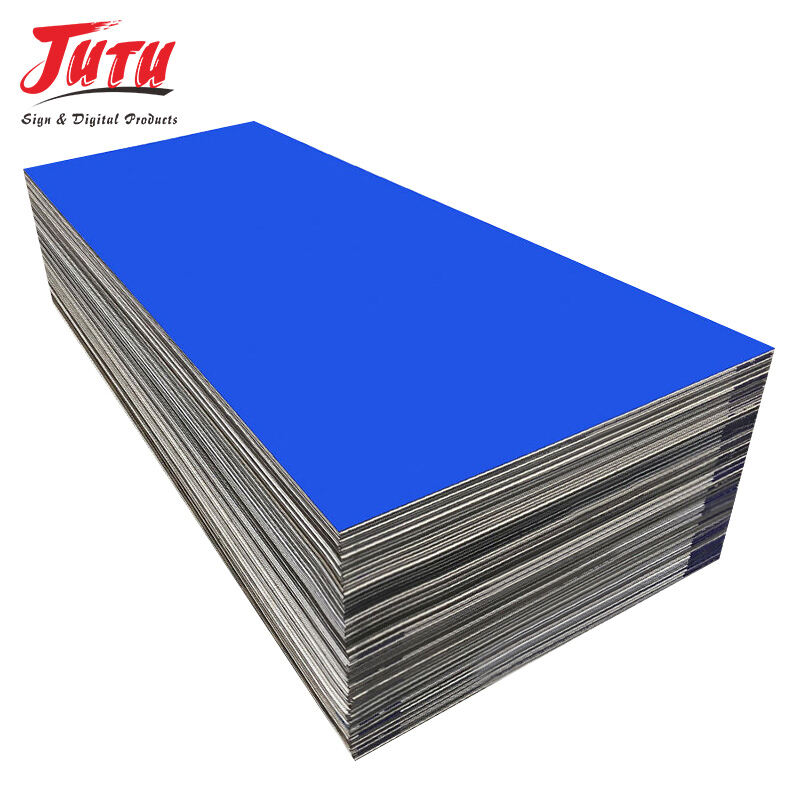

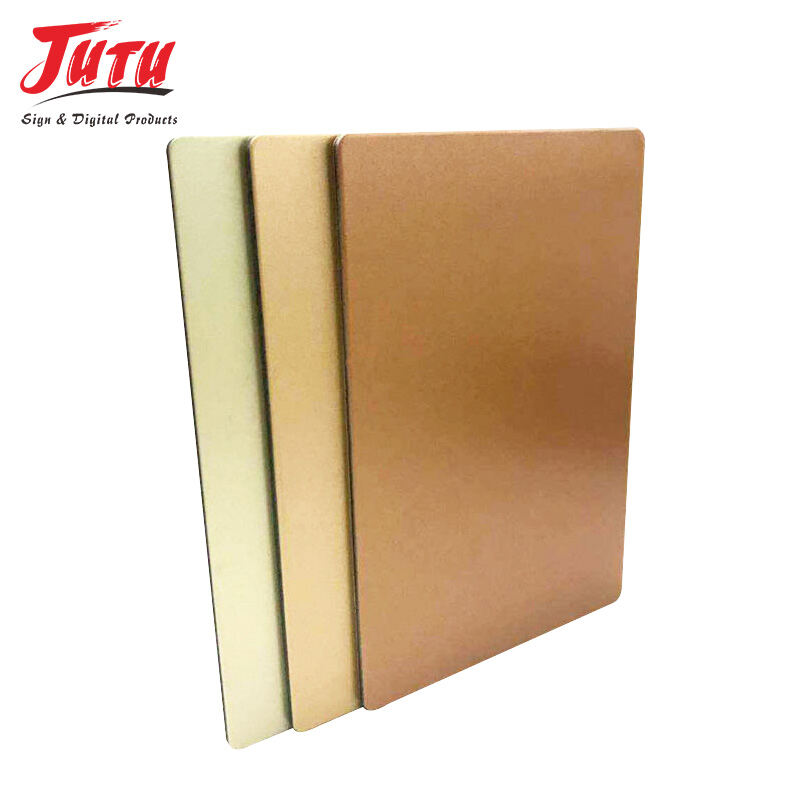

Aluminium composite panel fabrication represents a sophisticated manufacturing process that creates lightweight, durable building materials through the bonding of aluminum sheets with a polyethylene core. This advanced fabrication technique produces panels that serve multiple functions in modern construction, including exterior cladding, interior decoration, signage, and architectural elements. The manufacturing process involves precise lamination of two aluminum sheets, typically ranging from 0.21mm to 0.5mm thickness, with a thermoplastic core material that provides structural integrity and insulation properties. The technological features of aluminium composite panel fabrication include computer-controlled cutting systems, precision bending equipment, and specialized coating applications that ensure consistent quality and dimensional accuracy. These panels demonstrate exceptional weather resistance, maintaining their appearance and structural properties under extreme environmental conditions including UV exposure, temperature fluctuations, and moisture variations. The fabrication process incorporates advanced surface treatments such as PVDF coating, polyester finishing, and anodizing techniques that enhance corrosion resistance and aesthetic appeal. Applications for aluminium composite panel fabrication span across commercial buildings, residential projects, transportation infrastructure, and industrial facilities. The versatility of this fabrication method allows for custom shapes, sizes, and finishes that meet specific architectural requirements. Modern fabrication facilities utilize CNC machinery and automated production lines to achieve precise tolerances and consistent panel quality. The core material options in aluminium composite panel fabrication include fire-retardant polyethylene, mineral-filled cores, and honeycomb structures that provide varying degrees of fire resistance and structural performance. Quality control measures throughout the fabrication process ensure that each panel meets international standards for flatness, bond strength, and surface finish. The manufacturing technique also incorporates environmental considerations, with recyclable materials and energy-efficient production methods that minimize waste and reduce carbon footprint during the aluminium composite panel fabrication process.