wood aluminum composite panel

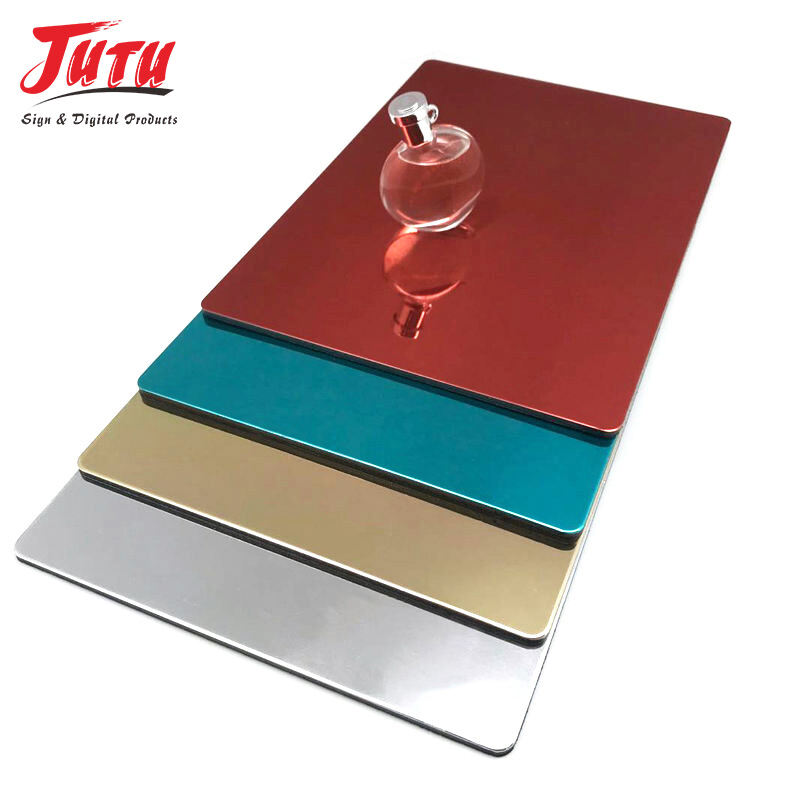

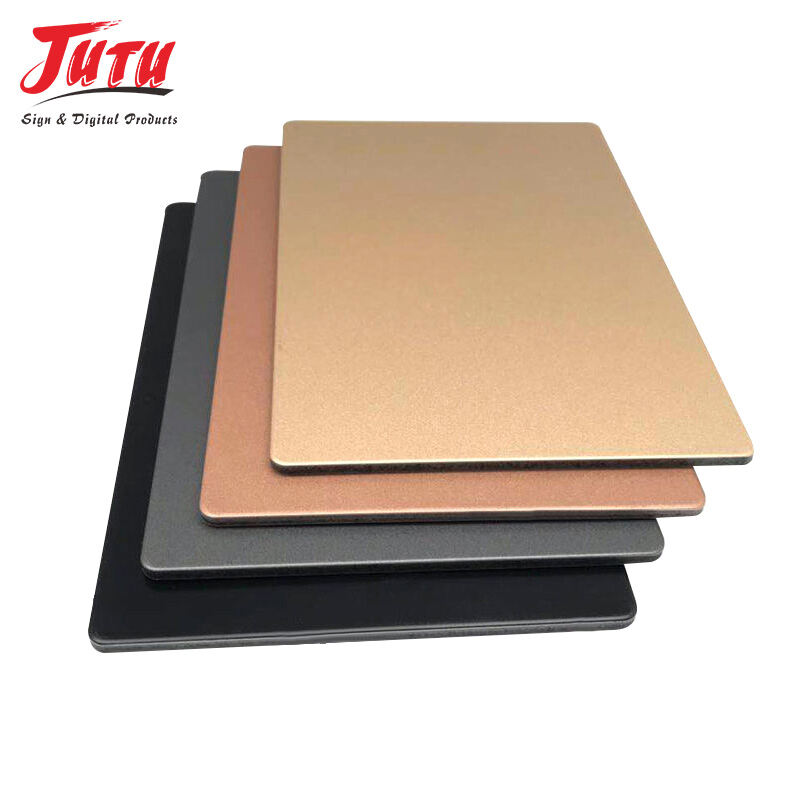

The wood aluminum composite panel represents a revolutionary building material that combines the natural beauty of wood with the durability and strength of aluminum. This innovative composite solution consists of two aluminum sheets bonded to a wood-based core, creating a lightweight yet robust panel system ideal for both interior and exterior applications. The wood aluminum composite panel offers architects, designers, and builders a versatile material that delivers exceptional performance while maintaining aesthetic appeal. The technological framework behind this material involves advanced bonding techniques that ensure superior adhesion between the aluminum exterior and wood interior components. The manufacturing process utilizes high-pressure lamination methods that create a seamless integration of materials, resulting in panels that resist warping, cracking, and delamination over time. The wood core typically consists of sustainably sourced timber or engineered wood products that provide structural integrity and thermal insulation properties. Meanwhile, the aluminum facings offer protection against moisture, UV radiation, and environmental weathering conditions. Primary functions of the wood aluminum composite panel include structural support, weather protection, thermal insulation, and decorative enhancement for building facades, interior walls, and architectural features. The panel system serves as an effective barrier against external elements while maintaining breathability that prevents moisture accumulation within wall assemblies. Temperature regulation becomes achievable through the natural insulating properties of the wood core, reducing energy consumption for heating and cooling systems. The wood aluminum composite panel also functions as a fire-resistant barrier when manufactured with appropriate fire-retardant treatments, meeting stringent building codes and safety requirements. Applications span across residential, commercial, and industrial construction projects, including exterior cladding systems, interior partition walls, ceiling installations, and decorative architectural elements. The versatility of the wood aluminum composite panel makes it suitable for modern office buildings, residential complexes, retail establishments, and institutional facilities where both performance and aesthetics matter significantly.