alumetal composite panel

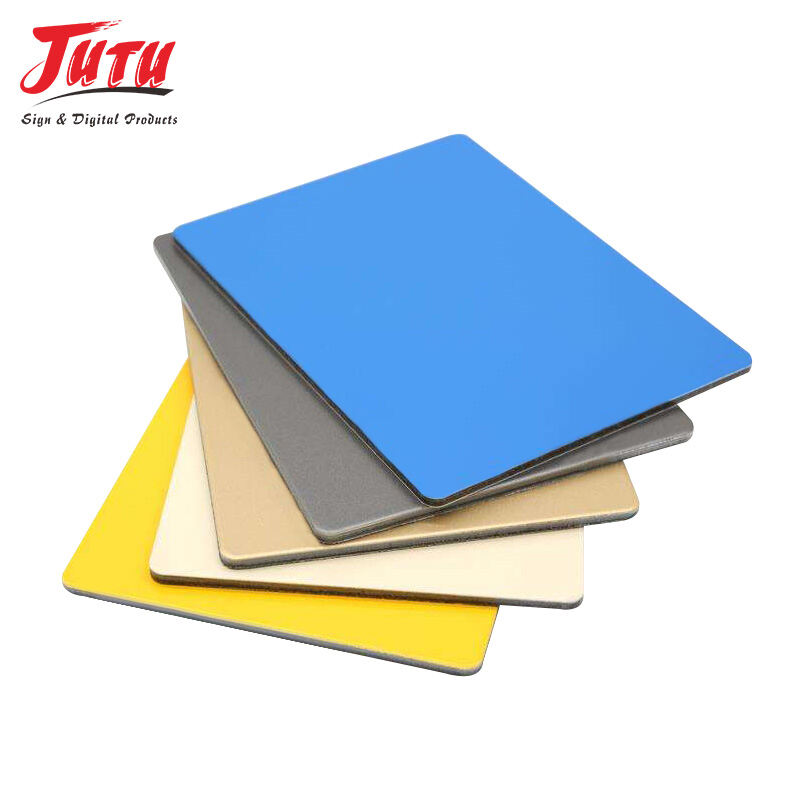

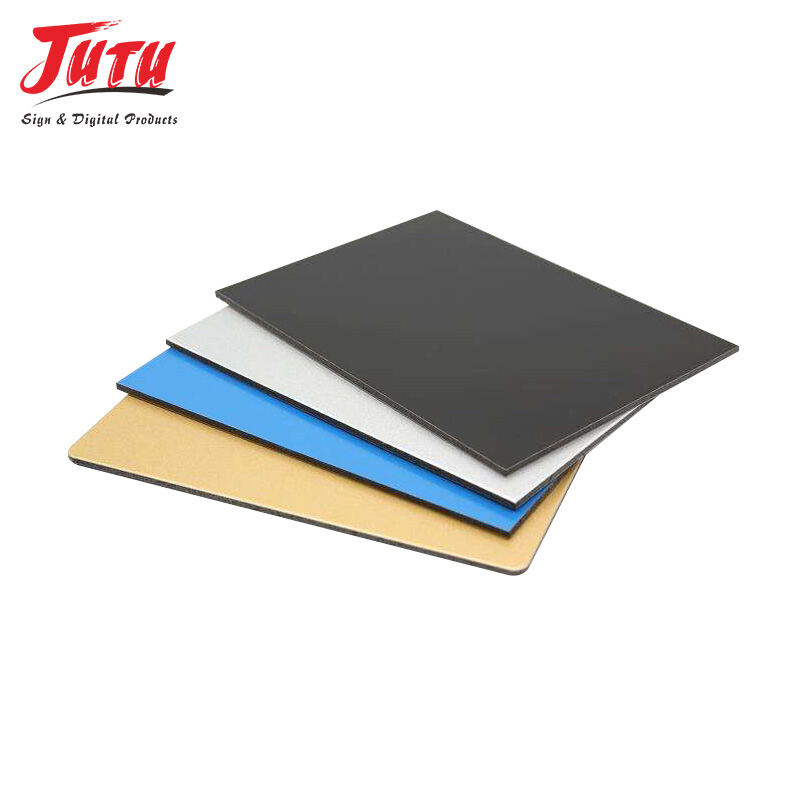

Alumetal composite panel represents a revolutionary building material that combines aluminum sheets with a polyethylene core to create versatile architectural solutions. This innovative construction material features two thin aluminum sheets bonded to both sides of a non-aluminum core, typically made from polyethylene or mineral-filled fire-retardant materials. The alumetal composite panel delivers exceptional performance across diverse construction projects, from commercial buildings to residential applications. The technological foundation of alumetal composite panel relies on advanced bonding techniques that ensure permanent adhesion between the aluminum faces and core material. This sophisticated manufacturing process creates a lightweight yet incredibly strong panel system that maintains structural integrity under various environmental conditions. The alumetal composite panel serves multiple functions in modern architecture, acting as both a protective barrier and aesthetic enhancement for building exteriors. Its primary functions include weather protection, thermal insulation, sound dampening, and visual appeal enhancement. The panel system effectively shields buildings from harsh weather elements while providing superior insulation properties that contribute to energy efficiency. Architects and designers frequently specify alumetal composite panel for curtain wall systems, building facades, interior partitions, and signage applications. The material excels in commercial construction projects where durability and appearance matter most. Shopping centers, office buildings, hospitals, and educational facilities commonly utilize alumetal composite panel systems to achieve modern, professional aesthetics. The technological features of alumetal composite panel include excellent flatness, dimensional stability, and resistance to thermal expansion. These characteristics ensure long-term performance without warping, buckling, or deterioration. The panel surface accepts various finishes, including powder coating, anodizing, and digital printing, allowing unlimited design possibilities. Installation versatility makes alumetal composite panel suitable for both new construction and renovation projects, providing architects with flexible design solutions.