Cost-Effective Installation and Maintenance Benefits

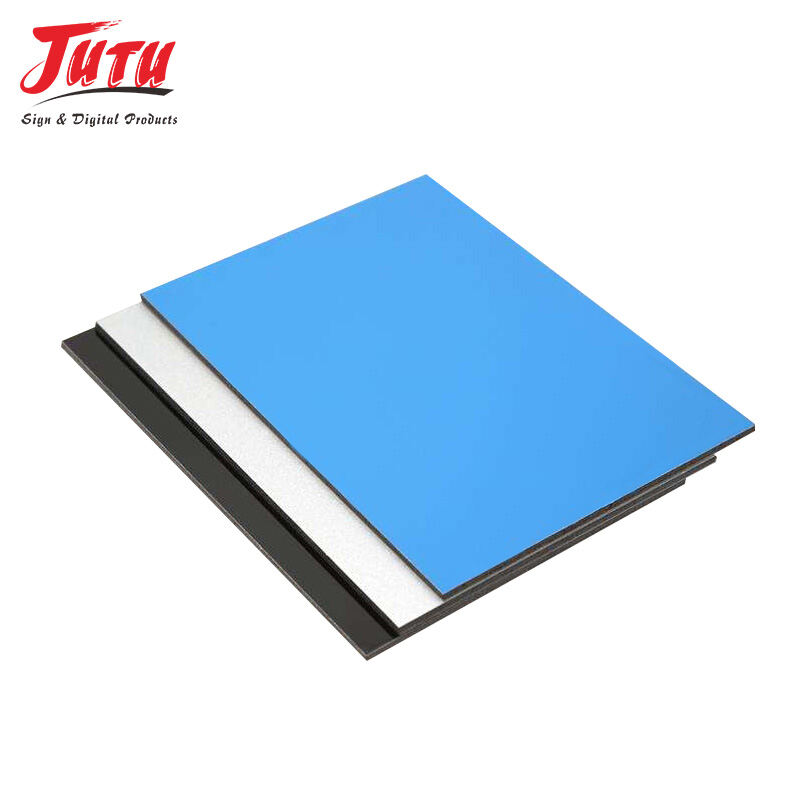

Aluminum composite panel cladding delivers substantial economic advantages through efficient installation processes and minimal ongoing maintenance requirements that benefit project budgets both during construction and throughout the building's operational life. The lightweight characteristics of aluminum composite panel cladding significantly reduce installation complexity and costs compared to heavier cladding materials that require extensive structural support systems and specialized lifting equipment. Installation crews can handle aluminum composite panel cladding efficiently with standard construction equipment, reducing labor costs and project timelines while improving job site safety conditions. The pre-fabrication capabilities of aluminum composite panel cladding systems allow for precise manufacturing of panels in controlled factory environments, eliminating weather-related delays and ensuring consistent quality that reduces installation problems and callbacks. Factory fabrication also enables complex cutting, forming, and finishing operations that would be difficult or impossible to perform on construction sites, resulting in higher quality installations at lower overall costs. The modular design of aluminum composite panel cladding installations simplifies replacement and repair procedures when damage occurs from severe weather, impacts, or normal wear over time. Individual panels can be removed and replaced without affecting adjacent panels or requiring extensive dismantling of surrounding building components. This replaceability feature provides long-term cost benefits by avoiding the total system replacement costs associated with other cladding materials when localized damage occurs. Maintenance requirements for aluminum composite panel cladding are minimal compared to materials that require regular painting, staining, or protective treatments to maintain their performance and appearance. The factory-applied finishes on aluminum composite panel cladding resist fading, chalking, and degradation for decades under normal exposure conditions, eliminating the recurring costs associated with refinishing building exteriors. Cleaning procedures for aluminum composite panel cladding typically involve simple washing with mild detergent solutions, eliminating the need for specialized cleaning chemicals or equipment that add to maintenance expenses. The non-porous surface characteristics of aluminum composite panel cladding prevent the accumulation of dirt, mildew, and biological growth that can compromise both appearance and performance of other cladding systems. Energy cost savings represent another significant economic benefit of aluminum composite panel cladding through improved thermal performance that reduces heating and cooling expenses. The insulating properties of the polyethylene core help stabilize interior temperatures and reduce the load on HVAC systems, resulting in measurable utility cost reductions over the building's operational life.