Outstanding Design Freedom and Aesthetic Appeal

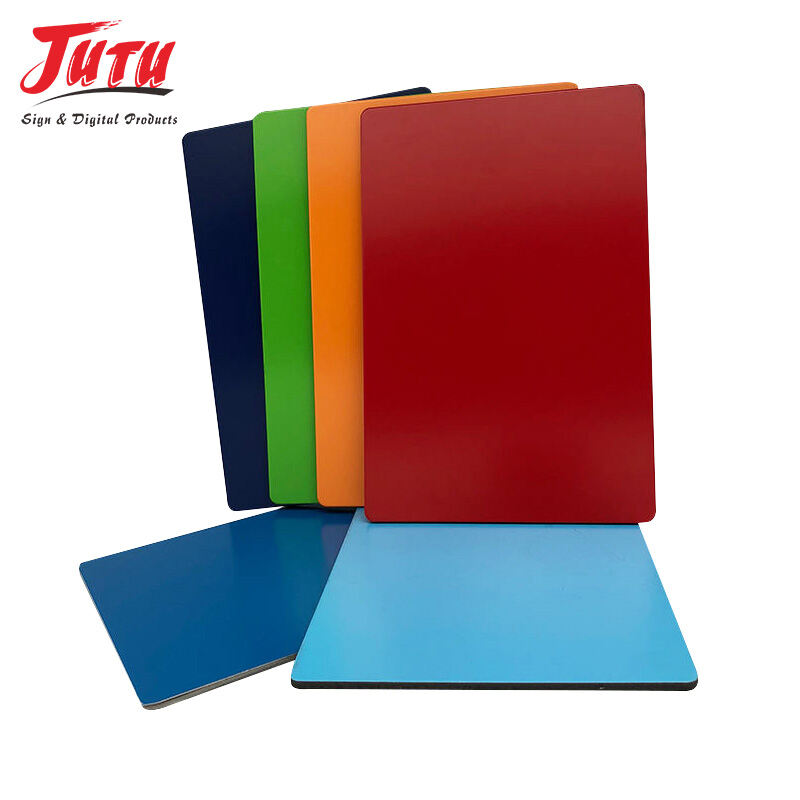

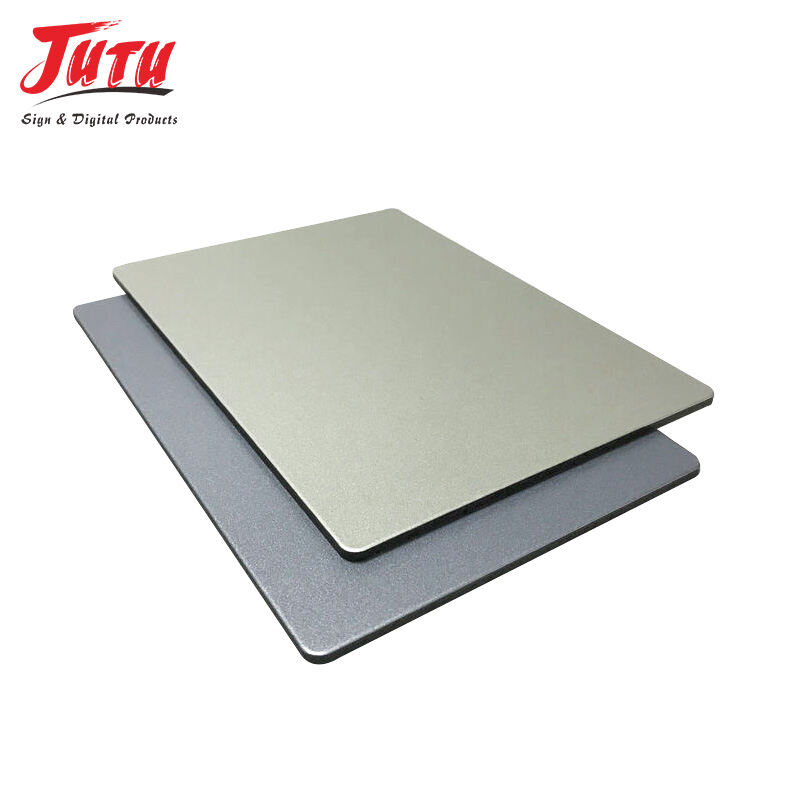

The alucoshine aluminum composite panel empowers architects and designers with unprecedented creative freedom, enabling innovative building designs that combine visual impact with practical performance. Surface finishing options include metallic, matte, glossy, textured, and wood-grain appearances that can replicate premium materials at a fraction of the cost while providing superior durability. Color stability technology ensures that vibrant hues and subtle tones maintain their intended appearance throughout the building's service life, resisting fading that commonly affects painted surfaces and other colored materials. Custom fabrication capabilities support unique architectural visions, with computer-controlled cutting and forming equipment enabling precise shapes, patterns, and dimensional accuracy that meets exacting design specifications. The alucoshine aluminum composite panel can be formed into complex three-dimensional shapes including curves, angles, and geometric patterns that create distinctive building facades and interior features. Perforation options allow for decorative screening applications while maintaining structural performance, enabling architects to balance privacy, light transmission, and aesthetic appeal. Surface textures range from smooth contemporary finishes to deeply embossed patterns that create visual interest and tactile appeal appropriate for various architectural styles. Integration with other building materials becomes seamless due to the panel's adaptability and the availability of coordinating trim pieces, transitions, and closure components. Lighting integration opportunities include backlit applications where translucent panels create dramatic visual effects for signage and architectural accent features. The lightweight nature of the alucoshine aluminum composite panel enables large-format installations that create impressive visual impact without requiring heavy structural support systems. Brand identity expression becomes possible through custom colors, logos, and graphics that can be applied or integrated during manufacturing. Digital printing capabilities allow for photographic images, complex graphics, and artistic designs to be permanently applied to panel surfaces, creating unique architectural statements that distinguish buildings from conventional structures.