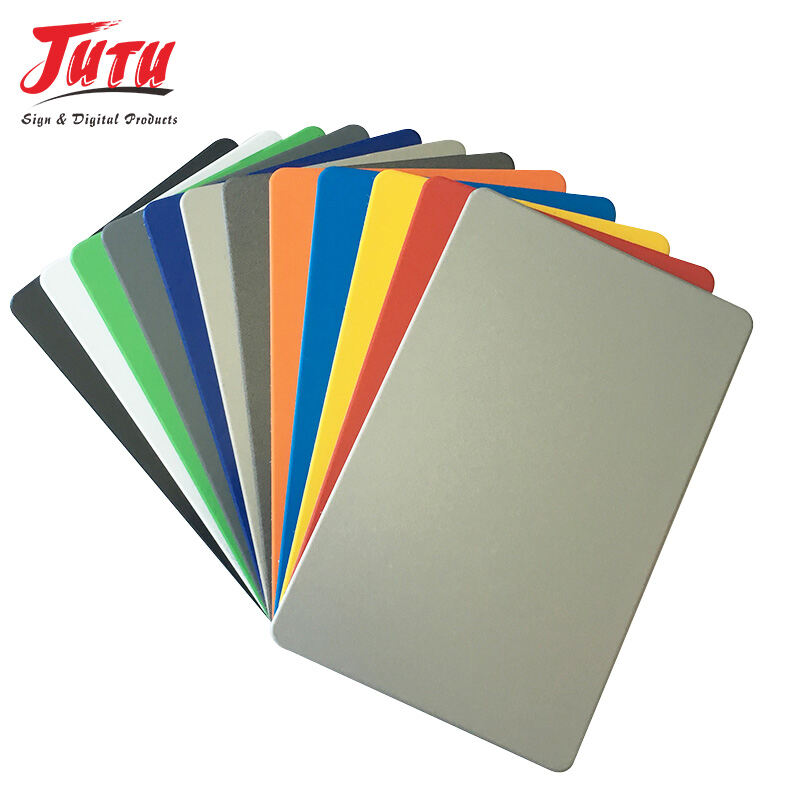

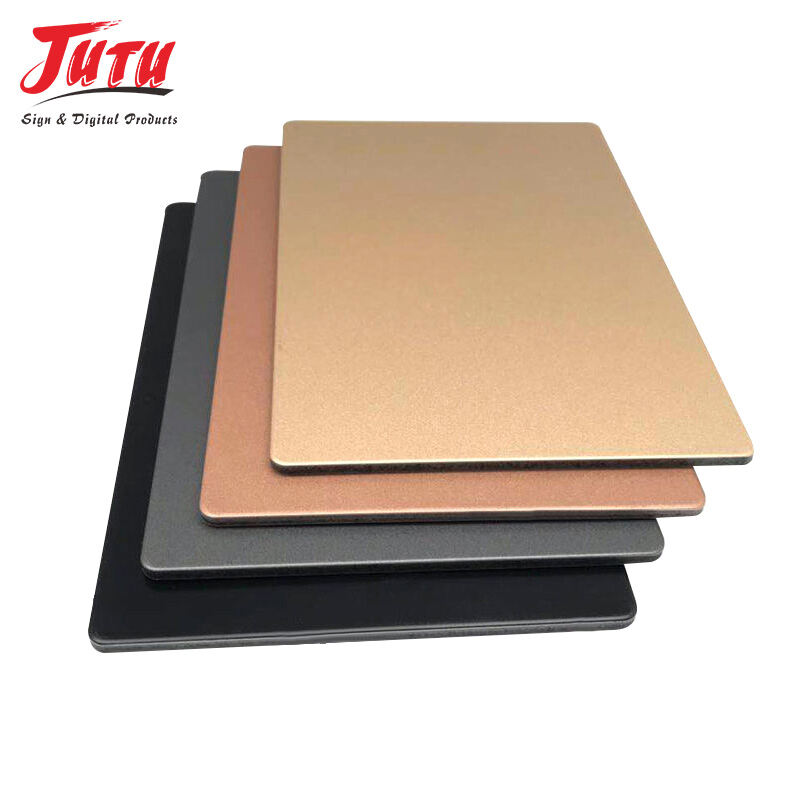

aluminum composite panel sheet

Aluminum composite panel sheet represents a revolutionary building material that combines superior performance with exceptional versatility in modern construction and architectural applications. This innovative material consists of two aluminum sheets bonded to a non-aluminum core, typically made of polyethylene or mineral-filled materials, creating a lightweight yet incredibly strong composite structure. The aluminum composite panel sheet delivers outstanding durability while maintaining cost-effectiveness, making it an ideal choice for both interior and exterior applications across residential, commercial, and industrial projects. The technological features of aluminum composite panel sheet include advanced coating systems that provide excellent weather resistance, UV protection, and color retention properties. The manufacturing process involves continuous lamination under controlled temperature and pressure conditions, ensuring consistent quality and optimal adhesion between layers. This sophisticated production method results in panels that exhibit superior flatness, dimensional stability, and resistance to thermal expansion. The core material selection significantly influences the panel's fire rating, thermal properties, and overall performance characteristics. Modern aluminum composite panel sheet incorporates cutting-edge surface treatments including PVDF fluorocarbon coatings, polyester finishes, and specialized protective films that enhance longevity and aesthetic appeal. The applications for aluminum composite panel sheet span across numerous industries and project types. In architectural cladding, these panels provide stunning facades that combine visual impact with practical protection against environmental elements. Interior designers utilize aluminum composite panel sheet for wall coverings, ceiling applications, and decorative elements due to its clean appearance and easy maintenance requirements. The signage industry extensively employs these panels for outdoor advertising displays, building identification systems, and promotional materials because of their excellent printability and weather resistance. Transportation sectors incorporate aluminum composite panel sheet in vehicle body construction, trailer manufacturing, and marine applications where weight reduction without compromising strength remains critical. The versatility extends to furniture manufacturing, exhibition displays, and specialized industrial equipment where the unique combination of lightweight properties and structural integrity proves invaluable for creating efficient, durable solutions.