aluminium composite sheet

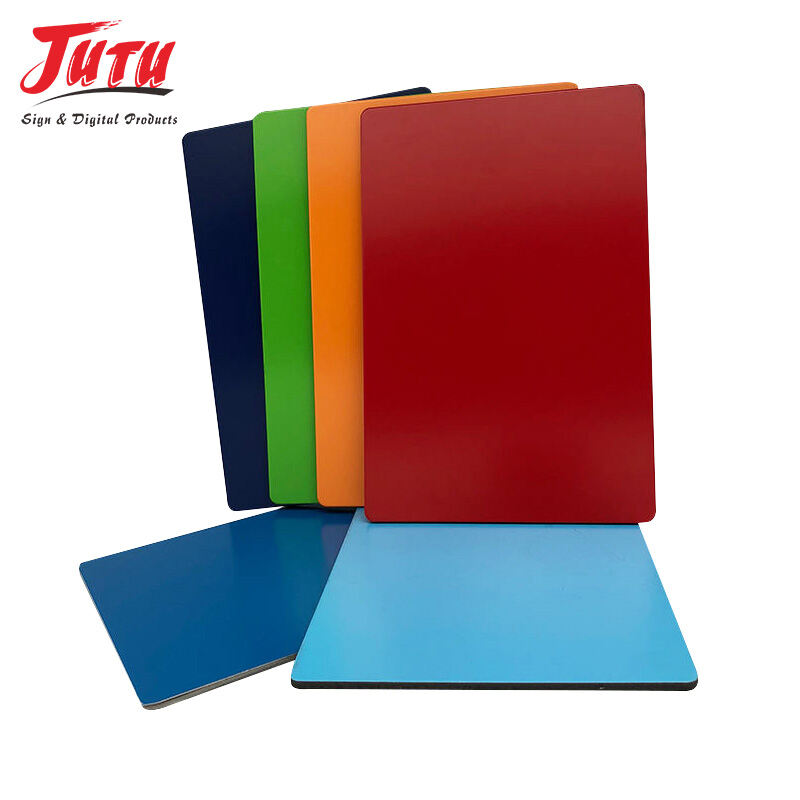

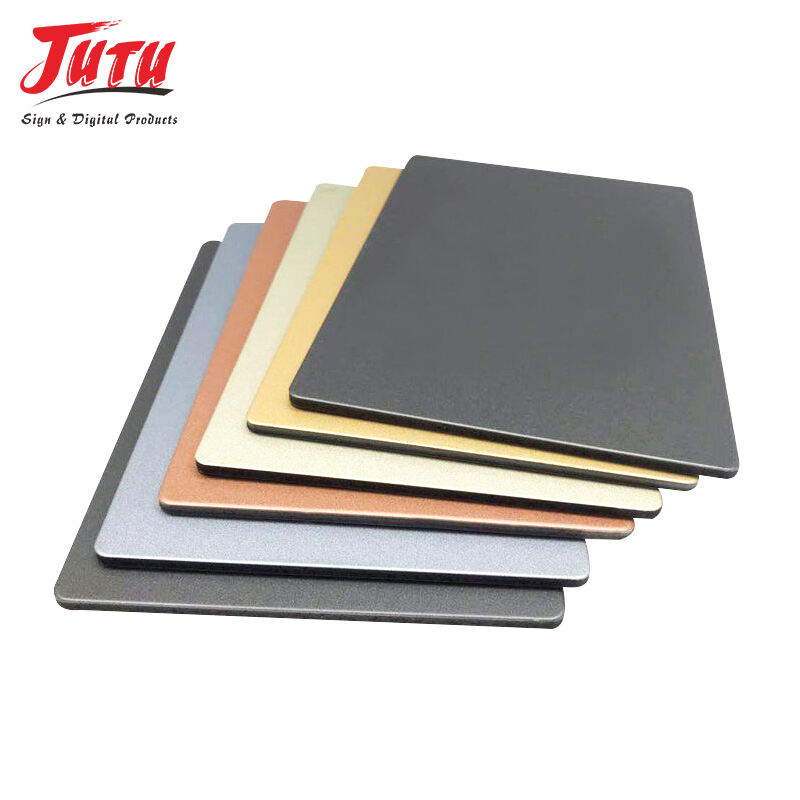

Aluminium composite sheet represents a revolutionary building material that has transformed modern construction and architectural design. This innovative product consists of two thin aluminium sheets bonded to a non-aluminium core, typically made from polyethylene, mineral-filled core, or fire-resistant materials. The aluminium composite sheet delivers exceptional performance through its unique three-layer construction, combining the strength and durability of aluminium with the lightweight properties and insulation benefits of the core material. The manufacturing process involves advanced bonding techniques that ensure permanent adhesion between layers, creating a homogeneous panel with superior structural integrity. These sheets typically range from 3mm to 6mm in thickness, with the aluminium skins usually measuring 0.3mm to 0.5mm each. The core material accounts for the majority of the panel thickness and determines many of the sheet's performance characteristics. Modern aluminium composite sheet production incorporates sophisticated coating technologies, including PVDF, polyester, and specialized protective finishes that enhance weather resistance and color retention. The panels can be manufactured in virtually unlimited colors, textures, and finishes, including metallic, wood grain, stone patterns, and solid colors. Advanced fabrication techniques allow for complex shaping, bending, and forming operations, making aluminium composite sheet suitable for curved facades, complex geometric designs, and intricate architectural details. Quality control measures during production ensure consistent thickness, flatness, and bonding strength across all panels. The material exhibits excellent thermal expansion properties, with controlled movement that prevents buckling or warping under temperature variations. Fire-resistant versions incorporate specially formulated cores that meet stringent building codes and safety standards. The aluminium composite sheet surface can accommodate various printing and graphics applications, making it popular for signage and branding purposes.