aluminium composite suppliers

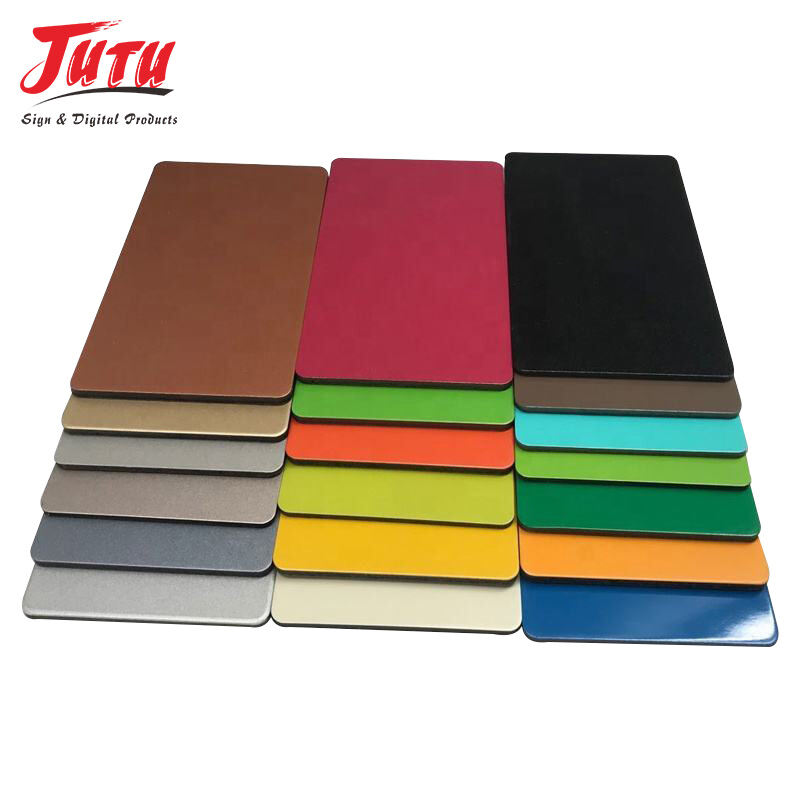

Aluminium composite suppliers represent a crucial segment of the modern construction and architectural materials industry, providing innovative solutions that combine the strength of aluminum with the versatility of composite materials. These specialized suppliers serve as the bridge between manufacturers and end-users, offering a comprehensive range of aluminum composite panels (ACPs) and related products that have revolutionized building facades, interior design, and industrial applications. The primary function of aluminium composite suppliers extends beyond simple product distribution, as they provide technical expertise, customization services, quality assurance, and ongoing support to architects, contractors, and construction professionals. Their role encompasses sourcing high-grade materials from certified manufacturers, maintaining extensive inventory systems, and ensuring consistent product availability for projects of all scales. Technologically, aluminium composite suppliers work with advanced materials featuring a unique sandwich construction consisting of two aluminum sheets bonded to a non-aluminum core, typically made of polyethylene, mineral-filled core, or fire-retardant materials. This sophisticated structure delivers exceptional properties including lightweight characteristics, superior flatness, excellent weather resistance, and outstanding durability. Modern aluminium composite suppliers utilize cutting-edge processing technologies such as digital printing, precision cutting systems, and specialized coating applications to meet diverse customer requirements. The applications served by aluminium composite suppliers span multiple industries, from commercial buildings and residential developments to transportation infrastructure and signage solutions. These suppliers cater to curtain wall systems, external cladding projects, interior partitions, ceiling installations, and decorative elements. Their expertise enables successful implementation in airports, shopping centers, hospitals, educational facilities, and high-rise buildings worldwide. The technological features offered through aluminium composite suppliers include advanced surface treatments, multiple finish options, custom color matching, and specialized profiles designed for specific installation methods, ensuring optimal performance in various environmental conditions and aesthetic requirements.