Exceptional Design Flexibility and Aesthetic Versatility

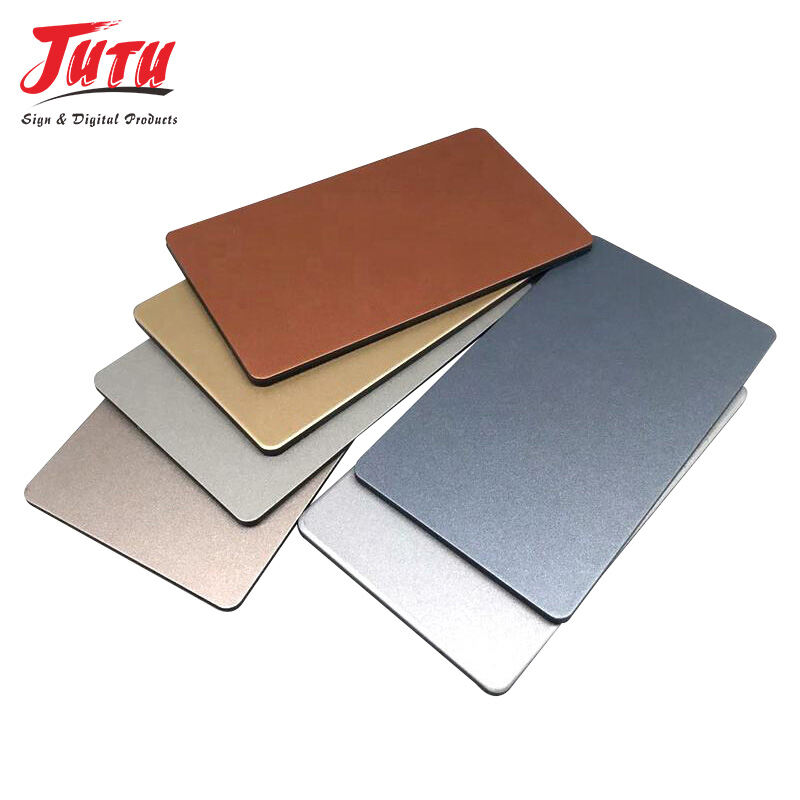

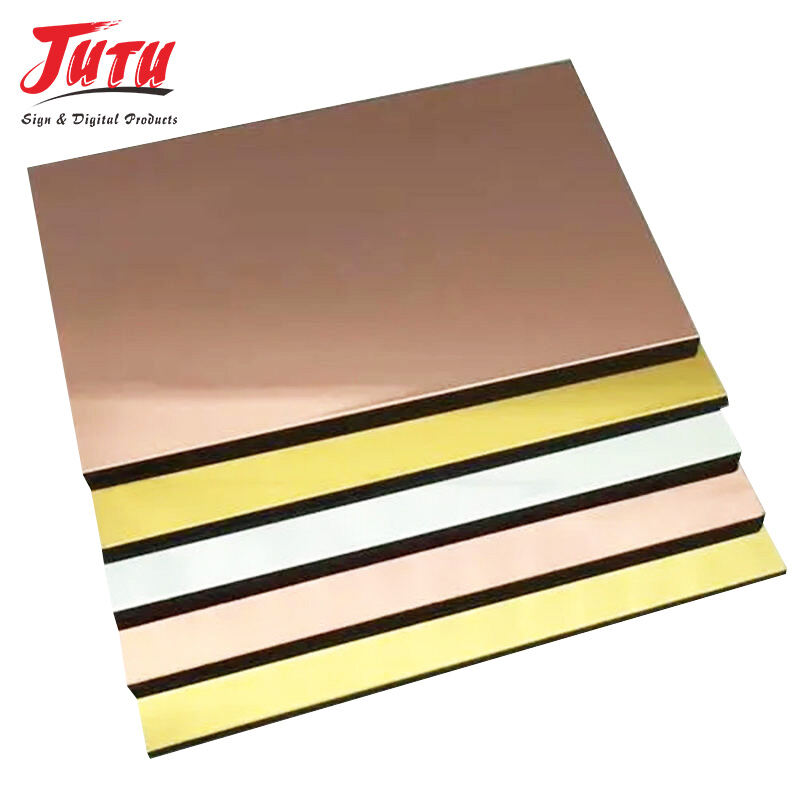

Alpolic composite panels revolutionize architectural design possibilities through their remarkable flexibility and aesthetic versatility, enabling architects and designers to realize complex geometric forms, dramatic curves, and innovative facade concepts that push the boundaries of conventional construction methods. The unique three-layer construction of these panels allows for precise bending, folding, and shaping operations that create seamless curved surfaces, sharp angles, and intricate architectural details without the need for expensive custom fabrication processes typically required with solid metal sheets or other rigid materials. Advanced fabrication techniques including CNC routing, laser cutting, and specialized forming equipment enable the creation of complex patterns, perforations, and three-dimensional textures that add visual interest and functional benefits to building facades. The extensive range of colors, finishes, and surface textures available in alpolic composite panels provides designers with virtually unlimited creative possibilities, from metallic finishes that mimic brushed aluminum or copper patina to bold solid colors and custom printed graphics that transform buildings into distinctive landmarks. Digital printing technologies compatible with alpolic composite panels allow for photorealistic images, corporate branding elements, and artistic designs to be permanently applied to panel surfaces, creating unique visual effects that enhance building identity and aesthetic appeal. The panels can be specified with various surface treatments including matte, gloss, textured, and specialty finishes that respond differently to lighting conditions throughout the day, creating dynamic facades that change appearance with varying natural and artificial illumination. Compatibility with modern curtain wall systems, structural glazing applications, and traditional mechanical fastening methods ensures that alpolic composite panels integrate seamlessly with other building components and systems. The ability to create both large uninterrupted surfaces and intricate detailed elements using the same base material simplifies design coordination and reduces the complexity of material specifications and installation procedures.