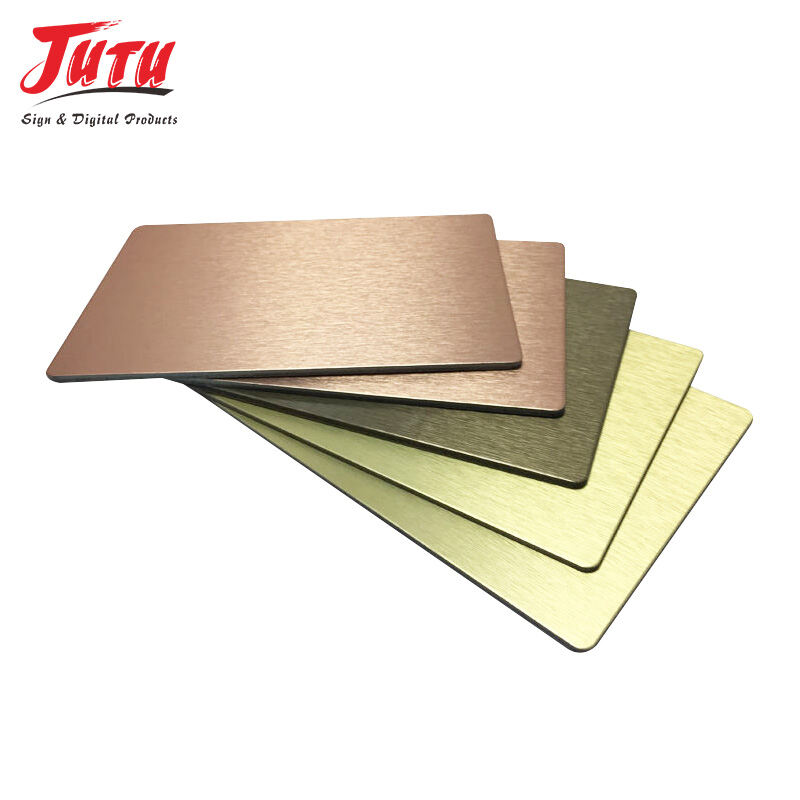

aluminium plastic composite panel

Aluminium plastic composite panel represents a revolutionary building material that combines the strength of aluminum with the versatility of plastic core materials. This innovative construction solution consists of two thin aluminum sheets bonded to a polyethylene core, creating a lightweight yet durable panel system. The aluminium plastic composite panel features a unique three-layer structure that delivers exceptional performance across various architectural applications. The outer aluminum layers provide superior weather resistance, corrosion protection, and aesthetic appeal, while the inner plastic core offers excellent insulation properties and flexibility. Manufacturing processes for aluminium plastic composite panel involve advanced lamination techniques that ensure perfect adhesion between layers, resulting in a homogeneous material with consistent quality. These panels typically measure 3-6mm in thickness, with standard dimensions reaching up to 2440mm in width and 6000mm in length. The aluminium plastic composite panel surface can be treated with various finishes including polyester coating, PVDF coating, or anodizing treatments, providing architects and designers with extensive customization options. Technological features include fire-resistant variants that meet international safety standards, ensuring compliance with building regulations worldwide. The core material options range from standard polyethylene to mineral-filled cores for enhanced fire performance. Installation methods for aluminium plastic composite panel systems utilize mechanical fixing systems or structural glazing techniques, accommodating both ventilated and non-ventilated facade applications. Quality control measures during production ensure dimensional stability, color consistency, and long-term performance reliability. Applications span commercial buildings, residential projects, industrial facilities, and transportation infrastructure, demonstrating the versatility of aluminium plastic composite panel solutions in modern construction.