acrylic golden sheet

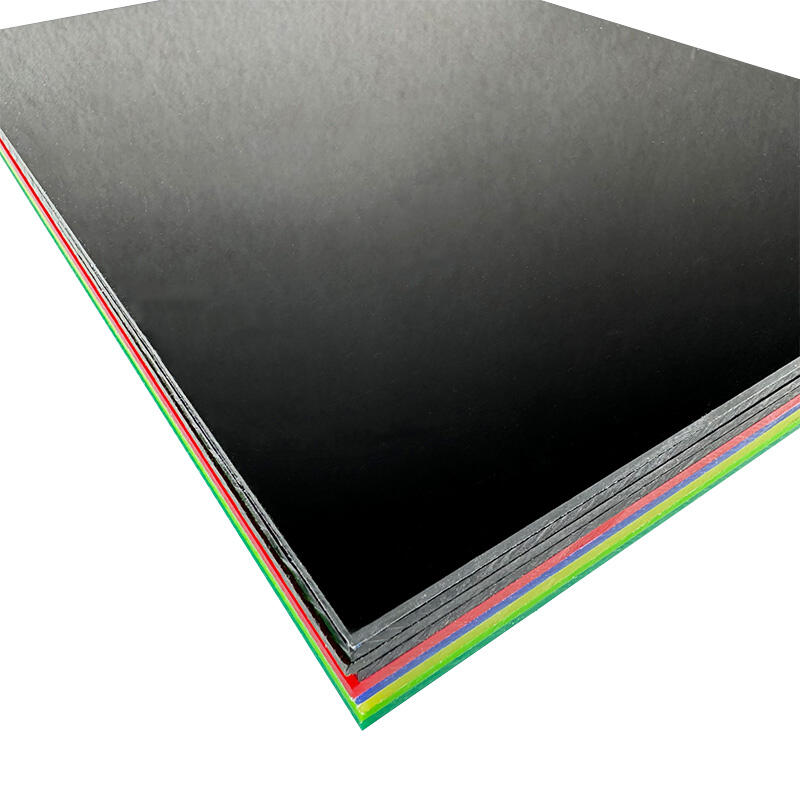

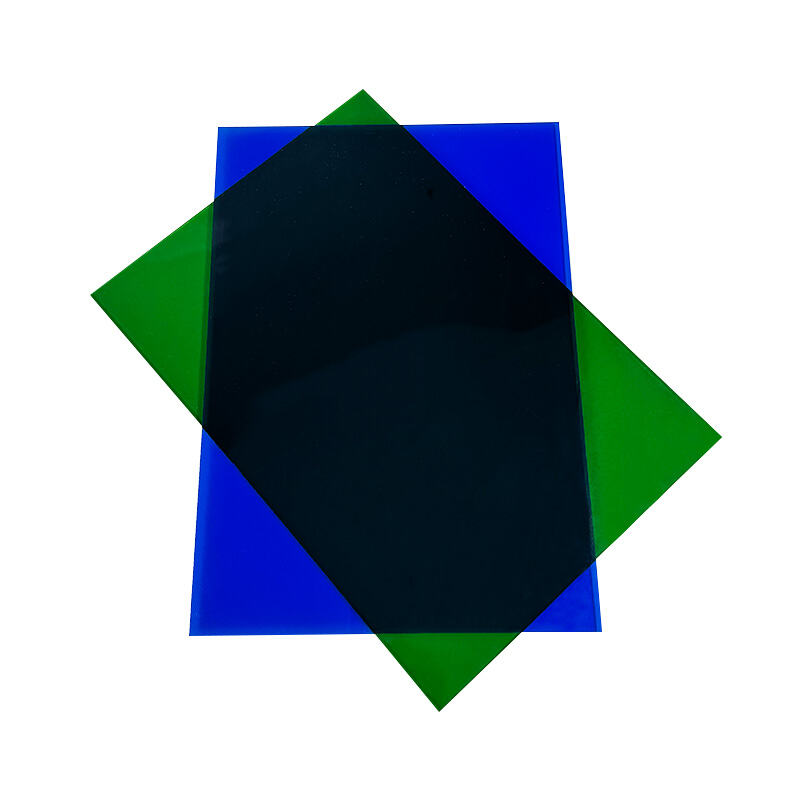

The acrylic golden sheet represents a revolutionary advancement in decorative and functional plastic materials, combining the exceptional clarity and workability of premium acrylic with an elegant golden finish that transforms ordinary surfaces into sophisticated design elements. This innovative material serves as a versatile solution for architects, designers, and manufacturers seeking to incorporate luxurious metallic aesthetics without the weight, cost, and maintenance challenges associated with genuine metal alternatives. The acrylic golden sheet features a specialized coating process that bonds metallic particles to high-grade acrylic substrates, creating a durable surface that maintains its lustrous appearance while offering superior optical properties and structural integrity. Technologically, this material incorporates advanced polymer chemistry that ensures excellent light transmission, impact resistance, and dimensional stability across varying temperature conditions. The manufacturing process involves precision extrusion techniques combined with specialized surface treatments that create uniform golden coloration without compromising the underlying acrylic's inherent properties. Applications for acrylic golden sheet span multiple industries, including architectural glazing, retail displays, automotive trim components, electronic device housings, and decorative panels for residential and commercial interiors. The material excels in environments where traditional metals would corrode, tarnish, or require extensive maintenance, making it particularly valuable for marine applications, humid climates, and high-traffic areas. Its lightweight nature facilitates easy installation and handling, while the golden finish provides consistent color matching across large installations. The acrylic golden sheet also demonstrates exceptional fabrication capabilities, allowing for cutting, drilling, bending, and welding using standard acrylic processing equipment, which significantly reduces manufacturing complexity and costs compared to metal alternatives.