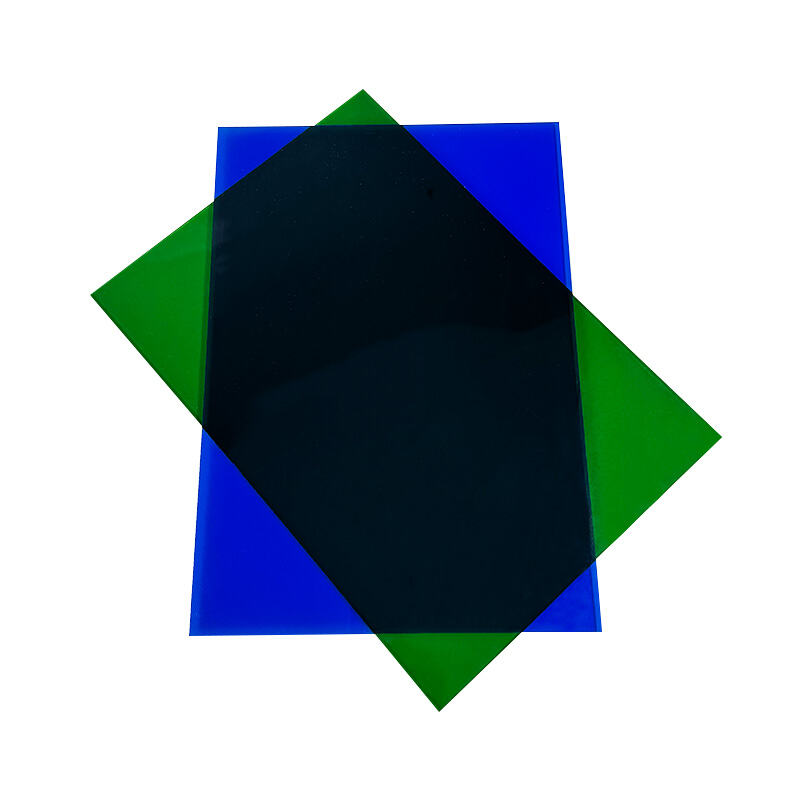

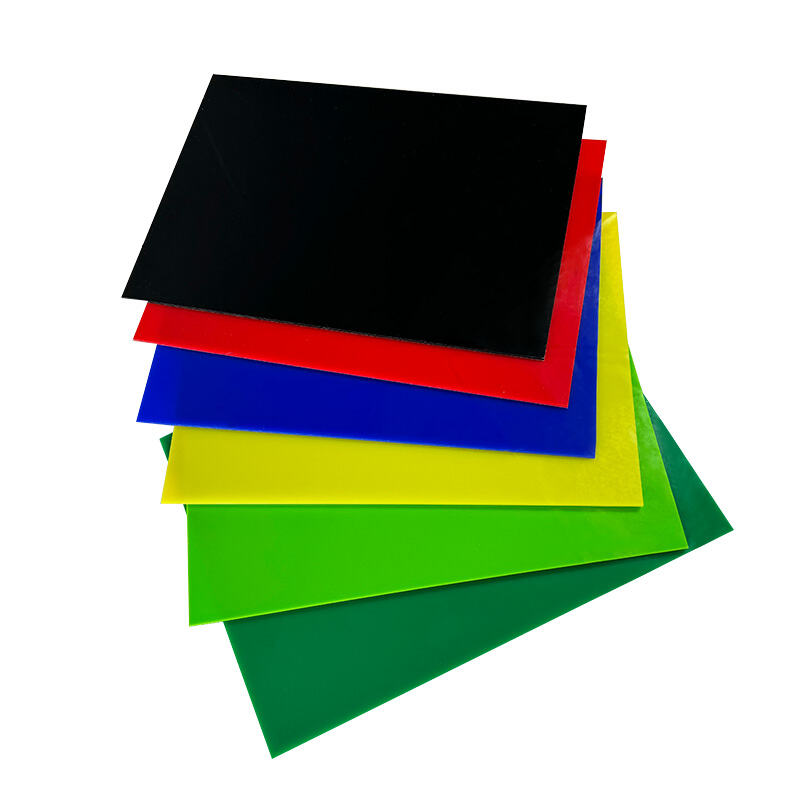

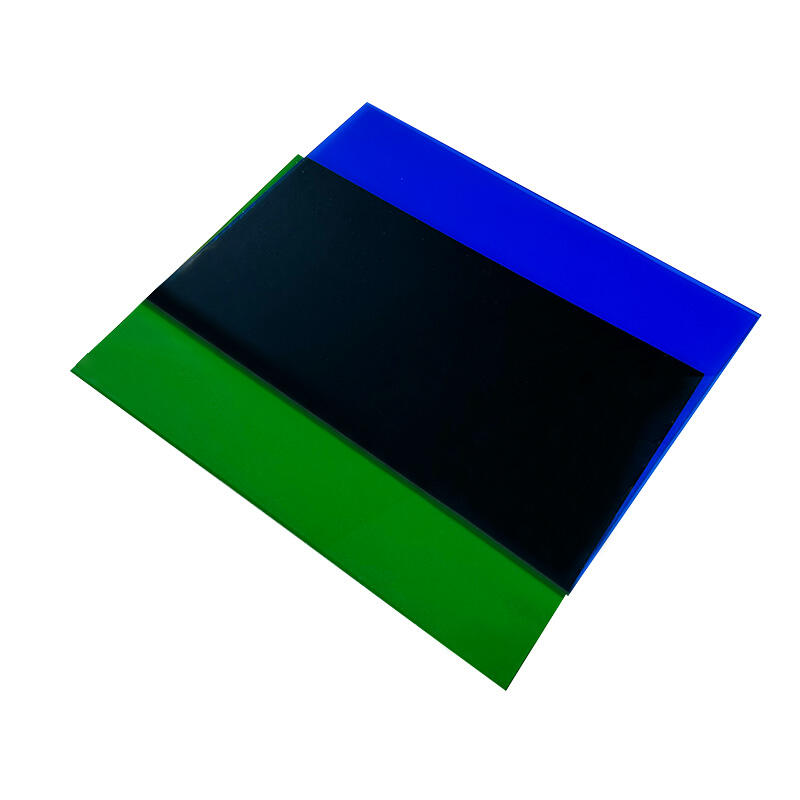

uv resistant acrylic sheet

UV resistant acrylic sheet represents a revolutionary advancement in polymer technology, specifically engineered to withstand the damaging effects of ultraviolet radiation while maintaining exceptional clarity and structural integrity. This specialized material combines the inherent benefits of traditional acrylic with advanced UV stabilization compounds, creating a versatile solution for both indoor and outdoor applications. The manufacturing process involves incorporating UV absorbers and light stabilizers directly into the acrylic polymer matrix, ensuring comprehensive protection throughout the entire thickness of the sheet. These additives work synergistically to absorb harmful UV wavelengths and convert them into harmless heat energy, preventing the degradation that typically occurs in standard plastics when exposed to sunlight. The technological foundation of UV resistant acrylic sheet relies on advanced polymer chemistry that maintains optical clarity while providing long-term durability. The material exhibits superior weather resistance, retaining its mechanical properties and visual appeal even after years of continuous outdoor exposure. Key technological features include enhanced molecular stability, improved thermal performance, and optimized light transmission characteristics. The sheet maintains excellent impact resistance, being significantly stronger than glass while weighing considerably less. Its chemical composition allows for easy fabrication, including cutting, drilling, bending, and bonding, making it highly adaptable for various manufacturing processes. Applications span numerous industries, from architectural glazing and signage to automotive components and marine equipment. The construction industry utilizes UV resistant acrylic sheet for skylights, canopies, and protective barriers, while the advertising sector relies on it for durable outdoor signage and display applications. Agricultural applications include greenhouse panels and livestock shelter windows, where the material's UV protection helps maintain optimal growing conditions while ensuring longevity. The versatility of UV resistant acrylic sheet extends to recreational applications such as swimming pool enclosures, outdoor furniture protection, and sports facility components, demonstrating its broad utility across diverse market segments.