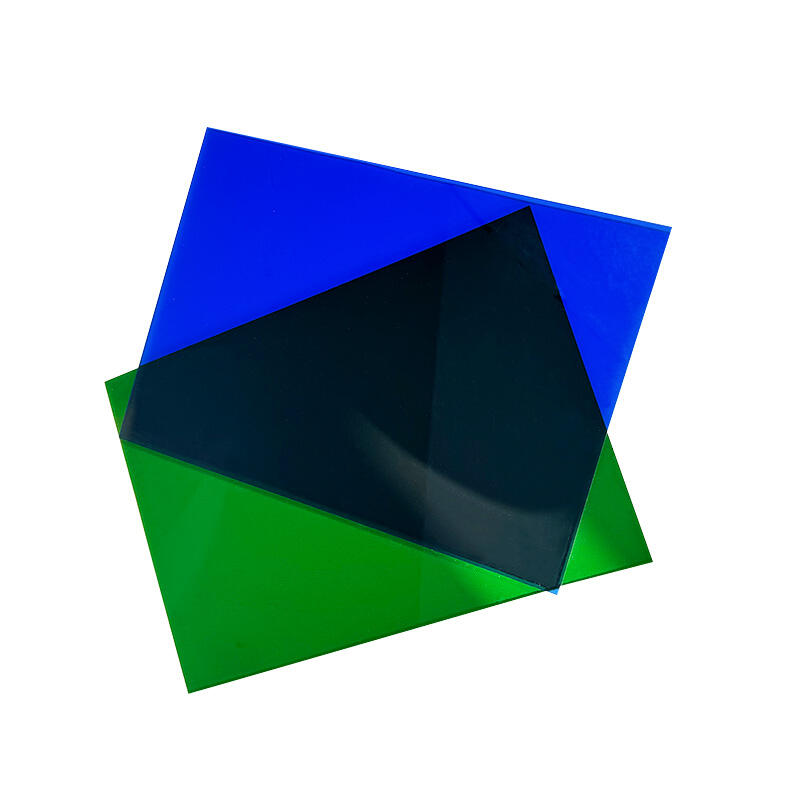

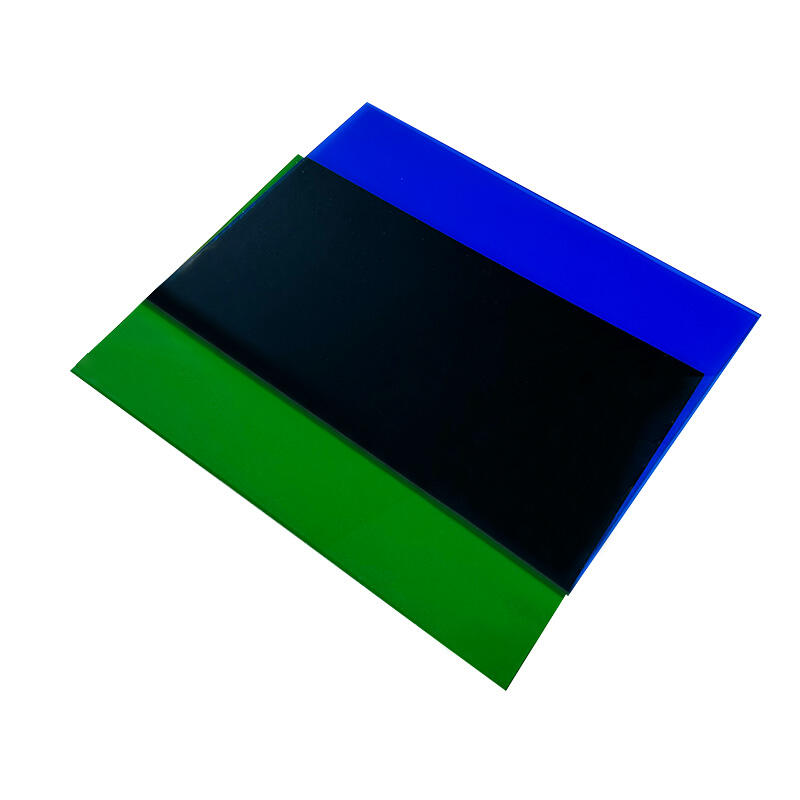

acrylic board distributor

An acrylic board distributor serves as a specialized equipment component designed to evenly distribute and control the flow of acrylic panels throughout manufacturing and processing environments. This sophisticated system incorporates advanced mechanical engineering principles to ensure precise handling of acrylic materials while maintaining optimal positioning accuracy. The acrylic board distributor functions as a critical interface between automated production lines and manual operations, facilitating seamless material transfer processes. Modern acrylic board distributor systems feature programmable logic controllers that enable operators to customize distribution patterns according to specific production requirements. These units typically include pneumatic actuators, precision sensors, and variable-speed drives that work together to create smooth material flow dynamics. The technological framework of an acrylic board distributor encompasses multiple integrated subsystems including conveyor mechanisms, alignment guides, and quality monitoring sensors. Advanced models incorporate servo-driven positioning systems that deliver exceptional repeatability and positioning accuracy within tight tolerances. The control interface allows operators to adjust distribution timing, speed parameters, and sequence patterns through intuitive touchscreen displays. Safety features include emergency stop functions, protective barriers, and sensor-based collision avoidance systems. Applications for acrylic board distributor systems span across diverse industries including signage manufacturing, architectural glazing, automotive components, and electronics enclosures. These systems prove particularly valuable in high-volume production environments where consistent material handling directly impacts overall efficiency and product quality. The modular design approach enables easy integration with existing production lines while providing flexibility for future expansion. Environmental considerations include energy-efficient motor systems and recyclable component materials that align with sustainable manufacturing practices.