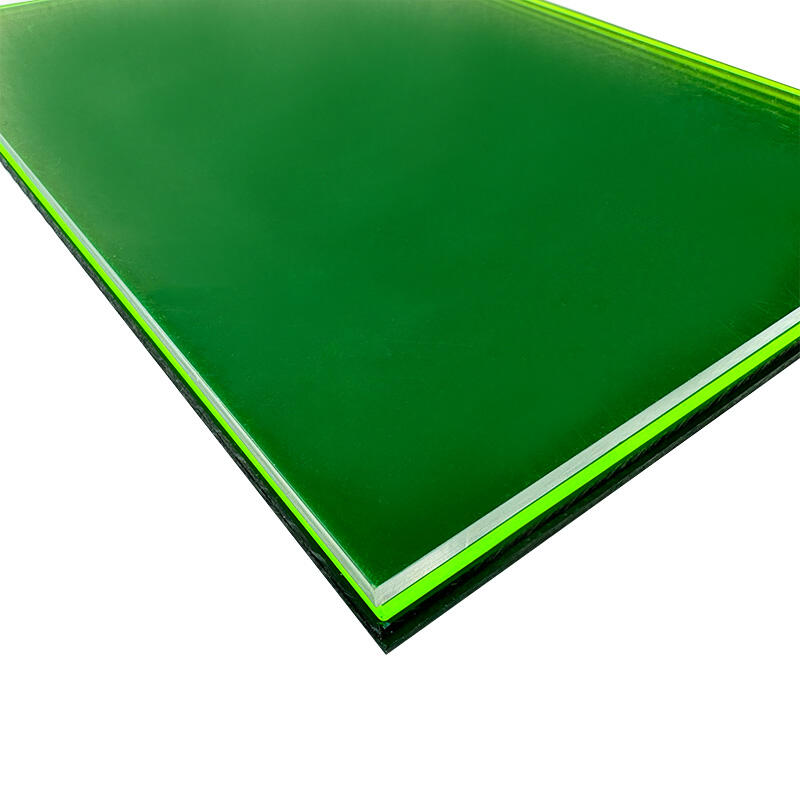

Revolutionary Impact Resistance and Safety Features

The exceptional impact resistance of acrylic sheets for aquarium installations revolutionizes safety standards in aquatic display construction, providing protection levels that far exceed traditional glass alternatives while maintaining superior optical performance. Engineering tests demonstrate that quality acrylic sheets for aquarium applications resist impact forces up to 17 times greater than equivalent glass thickness, virtually eliminating the risk of catastrophic failure that could endanger aquatic life, visitors, and facility operations. This remarkable durability stems from the inherent molecular flexibility of acrylic materials, which absorb and distribute impact energy rather than fracturing like brittle glass panels. The safety advantages become particularly crucial in high-traffic public aquariums, educational facilities, and residential settings where accidental impacts from visitors, equipment, or maintenance activities pose constant risks. Premium acrylic sheets for aquarium use demonstrate exceptional resistance to thermal shock, preventing stress fractures that commonly occur when glass panels experience rapid temperature changes during maintenance or environmental fluctuations. The fail-safe characteristics of acrylic materials ensure that even under extreme stress conditions, these panels crack gradually rather than shattering explosively, providing time for emergency response and minimizing potential harm to inhabitants and observers. Specialized acrylic sheets for aquarium installations incorporate advanced impact-resistant formulations that maintain structural integrity even after sustaining minor surface damage, unlike glass panels that can develop spreading cracks from small chips or scratches. The flexibility inherent in acrylic construction allows these materials to accommodate building settlement, seismic activity, and thermal expansion without developing stress points that could compromise structural integrity over time. Professional installation techniques for acrylic sheets for aquarium projects incorporate engineering principles that maximize impact resistance while ensuring optimal water pressure distribution across the entire panel surface. Quality manufacturers subject their acrylic sheets for aquarium applications to extensive testing protocols that simulate decades of operational stress, temperature cycling, and impact scenarios to guarantee long-term safety performance in real-world conditions.