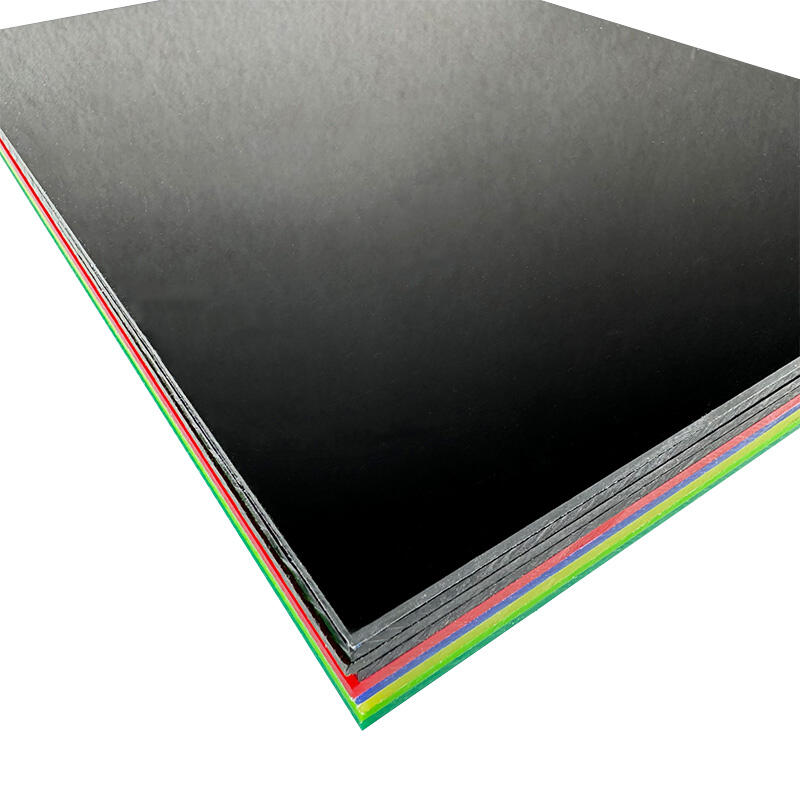

custom size acrylic sheet

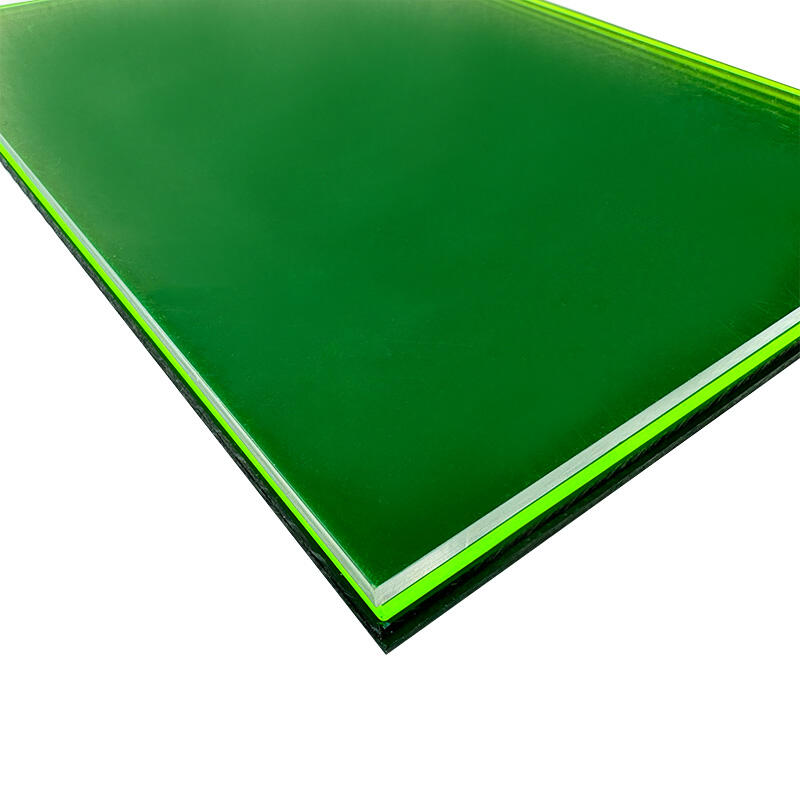

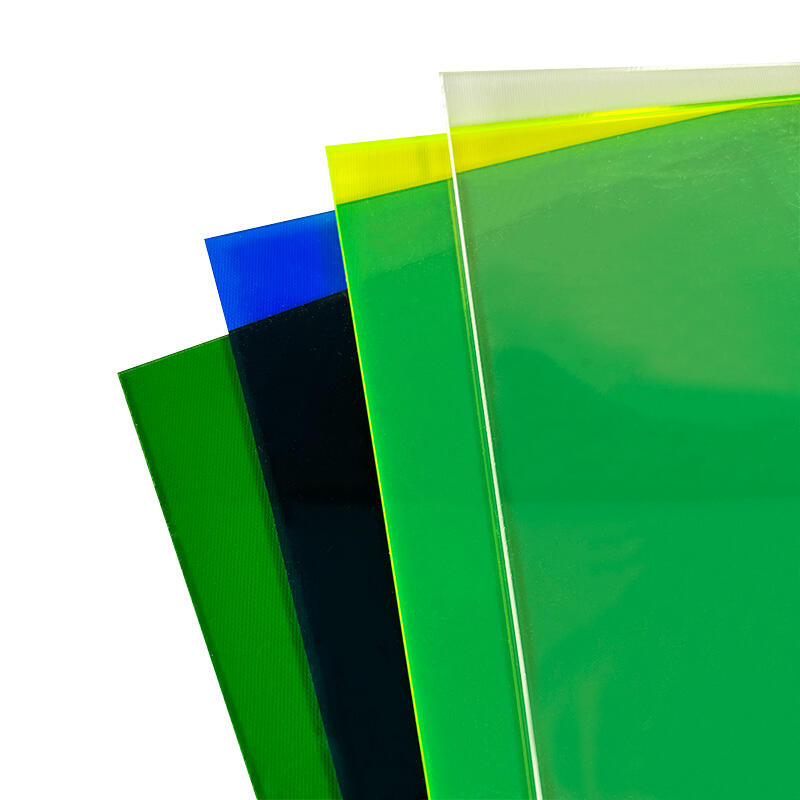

Custom size acrylic sheet represents a revolutionary solution in modern manufacturing and design applications, offering unparalleled flexibility for projects requiring precise dimensional specifications. These engineered plastic sheets are manufactured from high-quality polymethyl methacrylate (PMMA), delivering exceptional optical clarity that rivals traditional glass while maintaining superior impact resistance. The custom size acrylic sheet provides designers, architects, and manufacturers with the ability to order sheets cut to exact measurements, eliminating waste and reducing project costs. Advanced fabrication technologies enable precise cutting tolerances within millimeter accuracy, ensuring perfect fit for specialized applications. The material exhibits outstanding weather resistance, maintaining its structural integrity and visual appeal even under prolonged exposure to UV radiation and extreme temperature variations. Custom size acrylic sheet offers remarkable versatility in thickness options, ranging from ultra-thin 1mm sheets for delicate applications to robust 25mm panels for heavy-duty installations. The manufacturing process incorporates quality control measures that guarantee consistent material properties throughout each sheet, including uniform density, surface smoothness, and optical transmission rates exceeding 92 percent. These sheets demonstrate excellent machinability, allowing for secondary operations such as drilling, routing, and edge polishing without compromising structural integrity. The lightweight nature of custom size acrylic sheet, weighing approximately half that of equivalent glass panels, simplifies handling and installation procedures while reducing structural load requirements. Thermal forming capabilities enable complex curved shapes and three-dimensional configurations, expanding design possibilities beyond traditional flat panel applications. Chemical resistance properties protect against common solvents, cleaning agents, and environmental contaminants, ensuring long-term performance in demanding environments. The custom size acrylic sheet maintains dimensional stability across wide temperature ranges, preventing warping or distortion that could affect fit and function in precision applications.