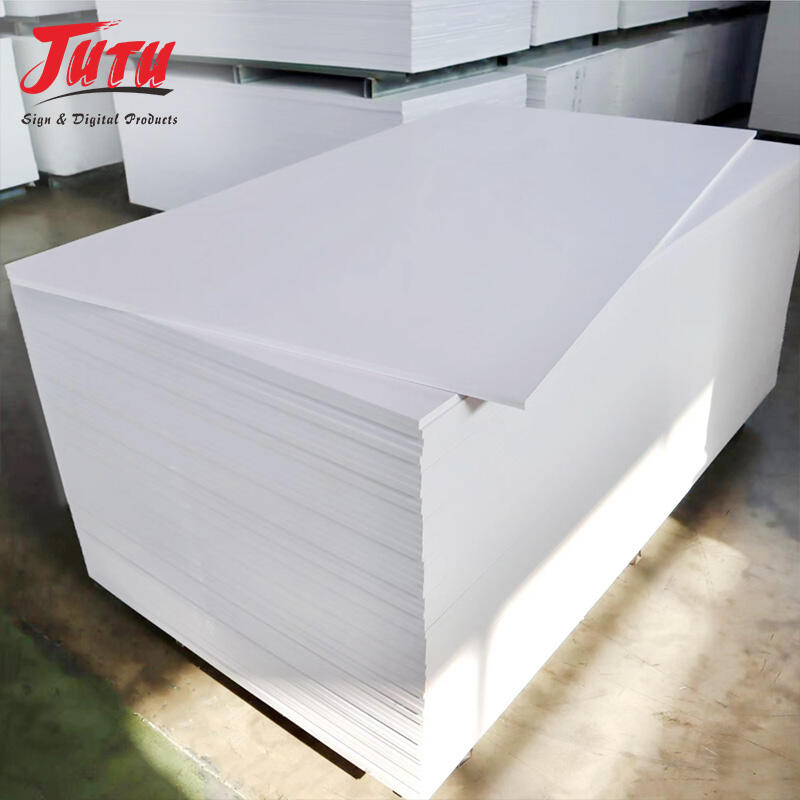

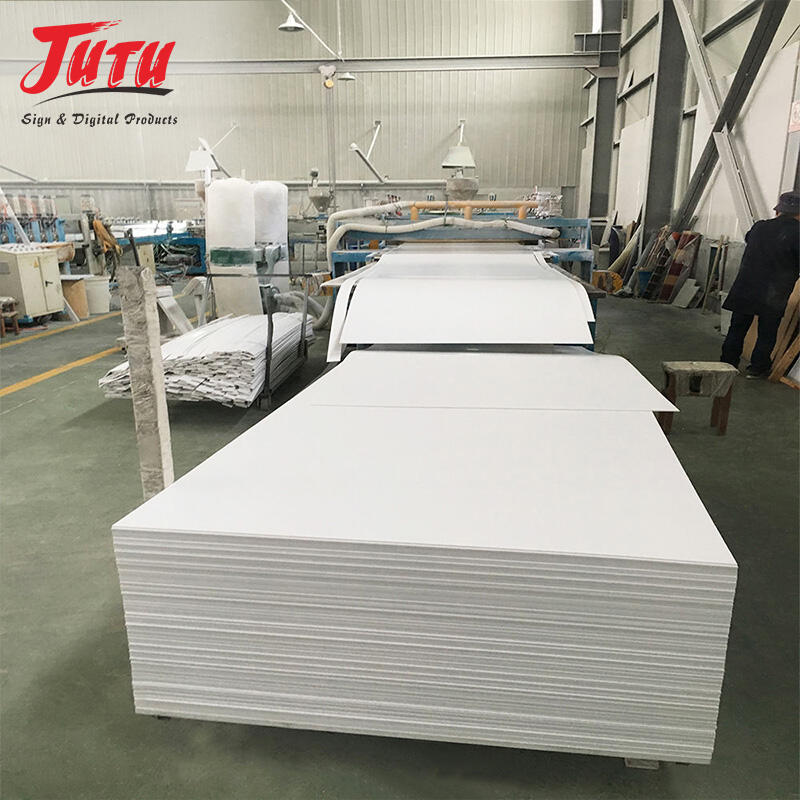

sunboard pvc foam sheets

Sunboard PVC foam sheets represent a revolutionary building material that combines durability, versatility, and cost-effectiveness in one comprehensive solution. These innovative sheets are manufactured using advanced closed-cell foam technology, creating a lightweight yet robust material that serves multiple construction and industrial applications. The unique cellular structure of sunboard PVC foam sheets provides exceptional strength-to-weight ratios while maintaining excellent thermal and acoustic insulation properties. The manufacturing process involves extruding PVC resin with specialized foaming agents, resulting in a uniform, closed-cell structure that resists moisture penetration and environmental degradation. These sheets feature smooth, non-porous surfaces on both sides, making them ideal for applications requiring hygiene and easy maintenance. The technological framework behind sunboard PVC foam sheets incorporates UV stabilizers and weather-resistant additives, ensuring long-term performance in outdoor environments. The material demonstrates remarkable chemical resistance, withstanding exposure to acids, alkalis, and various solvents without compromising structural integrity. Applications for sunboard PVC foam sheets span across construction, signage, marine industries, and architectural projects. In construction, these sheets serve as wall cladding, roofing substrates, and insulation panels for residential and commercial buildings. The signage industry utilizes sunboard PVC foam sheets for outdoor advertising displays, exhibition panels, and promotional materials due to their excellent printability and weather resistance. Marine applications include boat interiors, deck components, and storage compartments where moisture resistance is paramount. Architectural designers appreciate the material's ability to be easily cut, shaped, and formed into complex geometries while maintaining dimensional stability. The fire-retardant properties of sunboard PVC foam sheets meet international safety standards, making them suitable for public buildings and transportation infrastructure. These sheets also excel in temperature stability, performing consistently across wide temperature ranges without warping or cracking.