buy pvc foam board

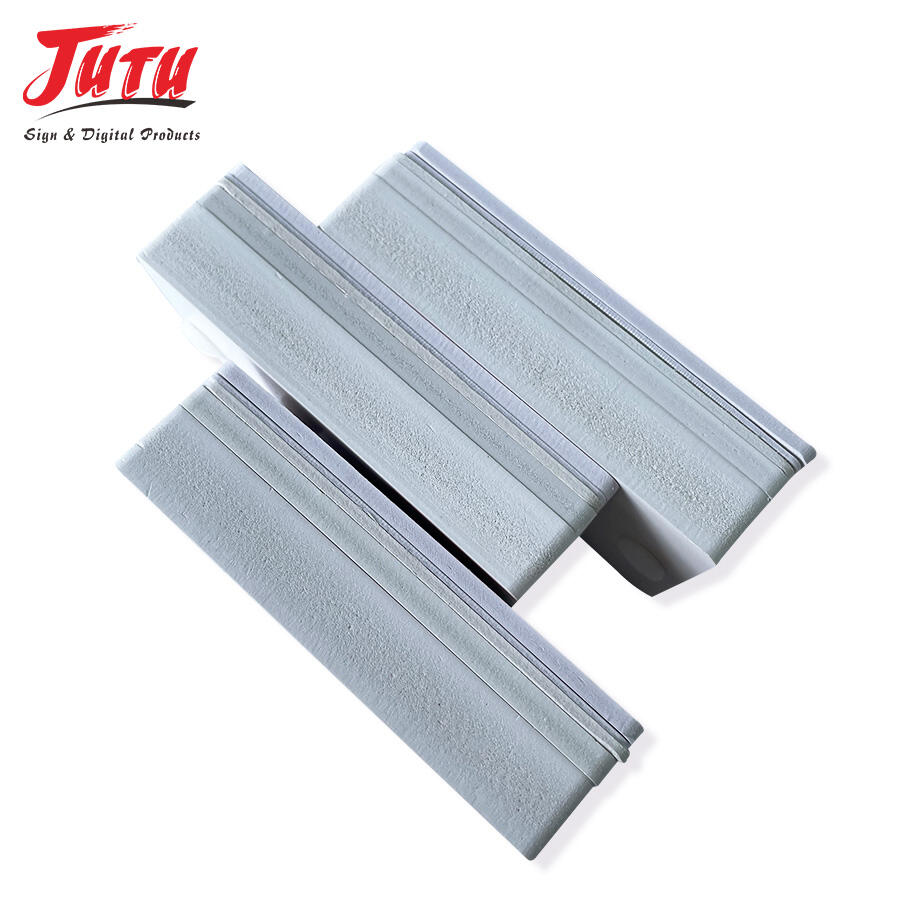

When you buy PVC foam board, you invest in one of the most versatile and reliable building materials available today. PVC foam board represents a revolutionary advancement in lightweight construction materials, combining exceptional durability with remarkable ease of use. This expanded polyvinyl chloride material features a unique cellular structure that delivers outstanding performance across numerous applications. The main functions of PVC foam board encompass structural support, insulation, waterproofing, and decorative purposes, making it an ideal choice for both commercial and residential projects. The technological features that set this material apart include its closed-cell foam structure, which provides excellent moisture resistance and thermal insulation properties. When you buy PVC foam board, you receive a material with superior dimensional stability that resists warping, shrinking, and expanding under temperature variations. The manufacturing process creates a uniform density throughout the board, ensuring consistent performance and reliable results in every application. The surface of PVC foam board accepts various finishing treatments, including painting, laminating, and printing, which expands its decorative possibilities significantly. Applications for PVC foam board span across multiple industries, from construction and signage to marine environments and exhibition displays. Builders frequently buy PVC foam board for exterior cladding, interior partitions, and roofing applications due to its excellent weather resistance. The signage industry relies heavily on this material for creating durable outdoor advertisements and indoor displays. Marine applications benefit from the board's moisture resistance and lightweight properties, making it perfect for boat interiors and deck construction. The material's chemical resistance allows it to withstand exposure to various environmental conditions without degradation. When you buy PVC foam board, you choose a material that maintains its structural integrity over extended periods, reducing maintenance costs and replacement frequency. The ease of fabrication makes PVC foam board particularly attractive to professionals and DIY enthusiasts alike, as it cuts cleanly with standard tools and accepts mechanical fasteners readily.