Superior Durability and Weather Resistance

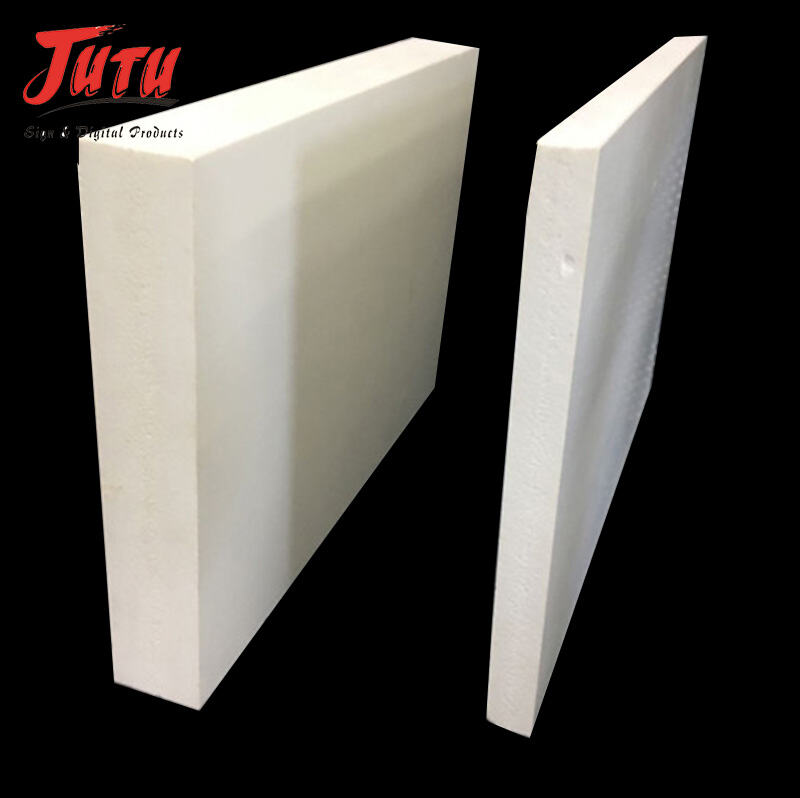

PVC integral foam board stands out in the construction industry due to its exceptional durability and comprehensive weather resistance that ensures decades of reliable performance in challenging environmental conditions. The advanced polymer chemistry of PVC integral foam board creates a material that withstands temperature fluctuations from extreme cold to intense heat without experiencing the expansion, contraction, or structural degradation that affects conventional materials. This thermal stability means that PVC integral foam board maintains its dimensional accuracy and mechanical properties across seasonal changes, eliminating the warping, cracking, and joint separation problems commonly encountered with wood, metal, and composite alternatives. The closed-cell foam structure of PVC integral foam board prevents water infiltration that causes freeze-thaw damage in colder climates, while the UV-stabilized polymer matrix resists photodegradation and color fading in sunny environments. Salt air, industrial pollutants, and acid rain have minimal impact on PVC integral foam board, making it particularly valuable for coastal installations and urban environments where other materials quickly deteriorate. The inherent chemical resistance extends to cleaning solvents, maintenance chemicals, and accidental spills, ensuring that routine building maintenance does not compromise the material's integrity or appearance. Unlike wood products that require regular staining, sealing, or replacement, PVC integral foam board maintains its protective properties and aesthetic appeal with minimal intervention, reducing long-term ownership costs significantly. The material's resistance to biological degradation means that insects, rodents, and microorganisms cannot compromise its structural integrity, eliminating pest-related damage and the associated repair costs. Impact resistance of PVC integral foam board exceeds that of many traditional materials, withstanding accidental damage from hail, debris, and mechanical contact without requiring immediate replacement. This comprehensive durability package makes PVC integral foam board an investment that pays dividends through reduced maintenance, extended service life, and consistent performance that property owners can rely on for years to come.