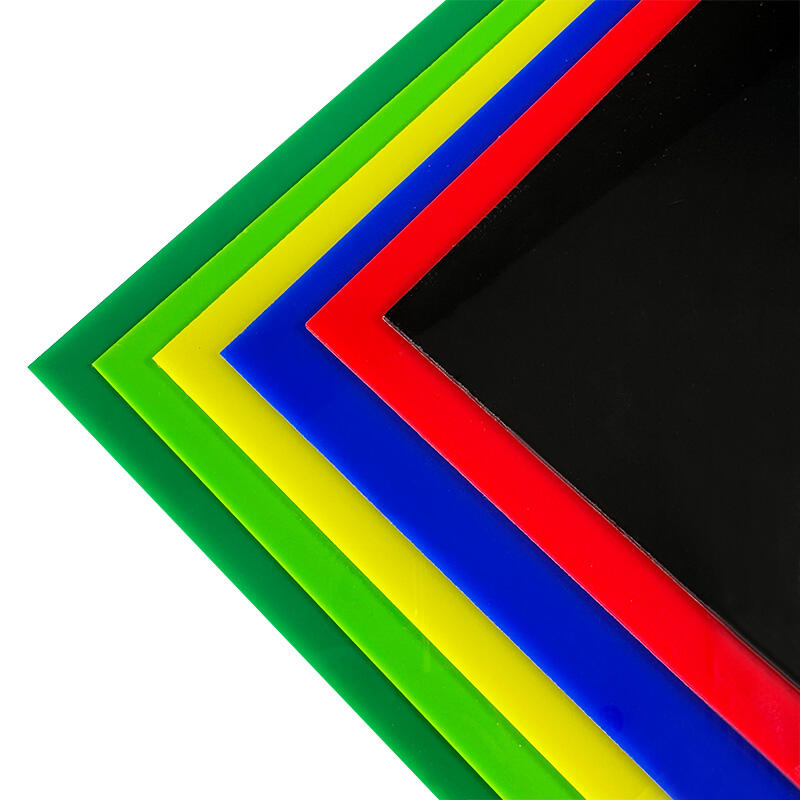

glitter acrylic sheets

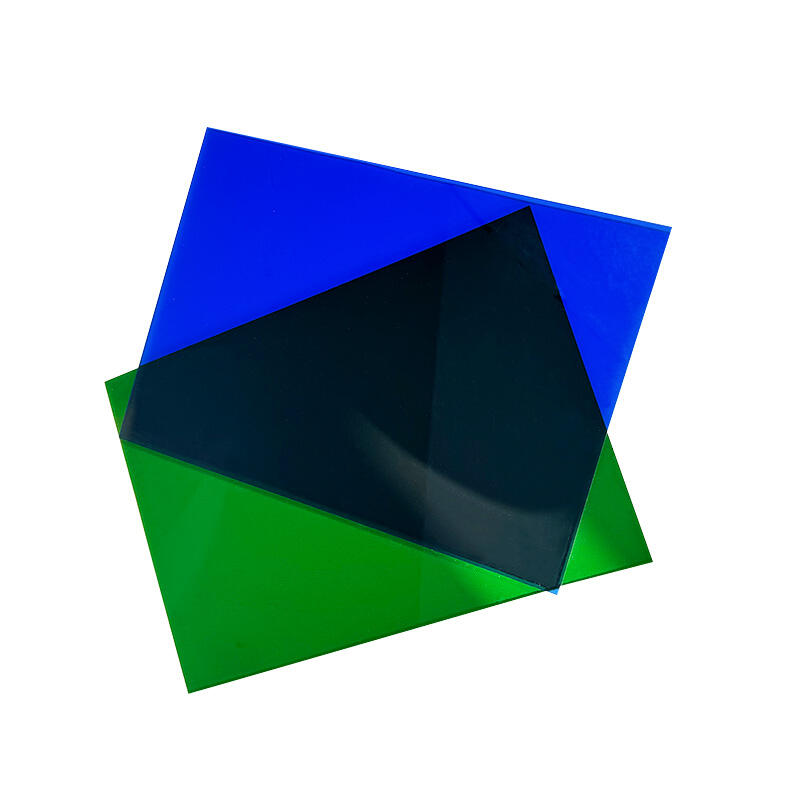

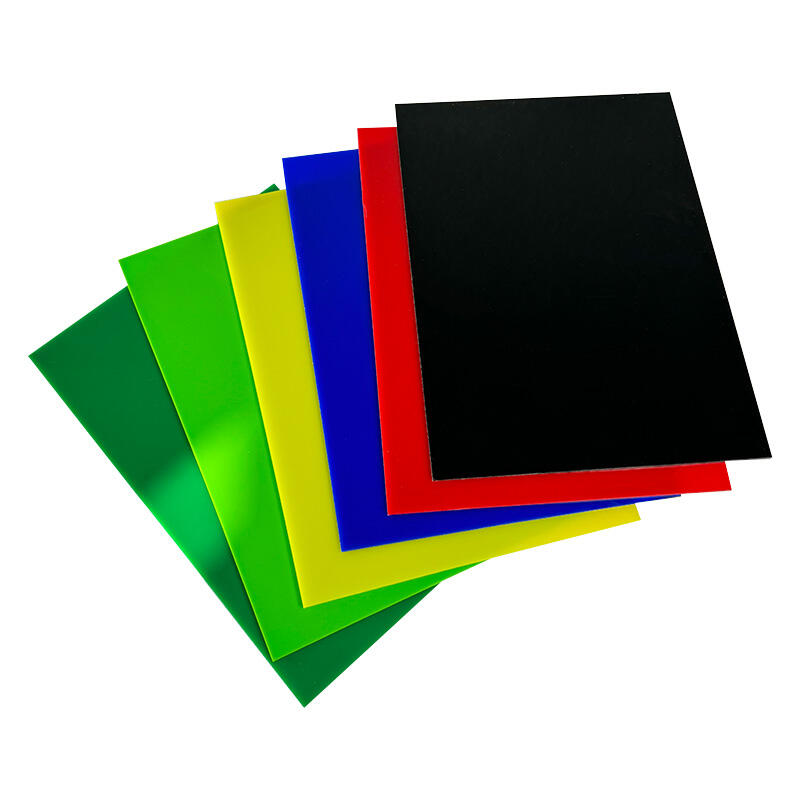

Glitter acrylic sheets represent a revolutionary material that combines the clarity and durability of traditional acrylic with the captivating sparkle of embedded glitter particles. These specialized sheets are manufactured through an advanced process where high-quality glitter is permanently embedded within the acrylic polymer matrix during production, creating a stunning visual effect that remains intact throughout the material's lifespan. The glitter acrylic sheets maintain excellent optical properties while delivering exceptional aesthetic appeal, making them ideal for both decorative and functional applications. The manufacturing process ensures that glitter particles are evenly distributed throughout the thickness of the sheet, preventing separation or settling over time. This innovative material offers superior light transmission properties, allowing natural and artificial light to interact with the embedded glitter particles to create mesmerizing sparkle effects. The technological features of glitter acrylic sheets include excellent weather resistance, UV stability, and chemical resistance, making them suitable for both indoor and outdoor applications. These sheets can be easily fabricated using standard acrylic processing techniques, including cutting, drilling, bending, and polishing. The material maintains structural integrity even when subjected to temperature variations, ensuring long-lasting performance in diverse environments. Applications for glitter acrylic sheets span across multiple industries, from architectural design and interior decoration to retail displays and signage. The sheets are commonly used in commercial spaces, hospitality venues, entertainment facilities, and residential projects where visual impact is paramount. Their versatility extends to furniture manufacturing, lighting fixtures, partition walls, and custom fabrication projects that require both functionality and aesthetic excellence.