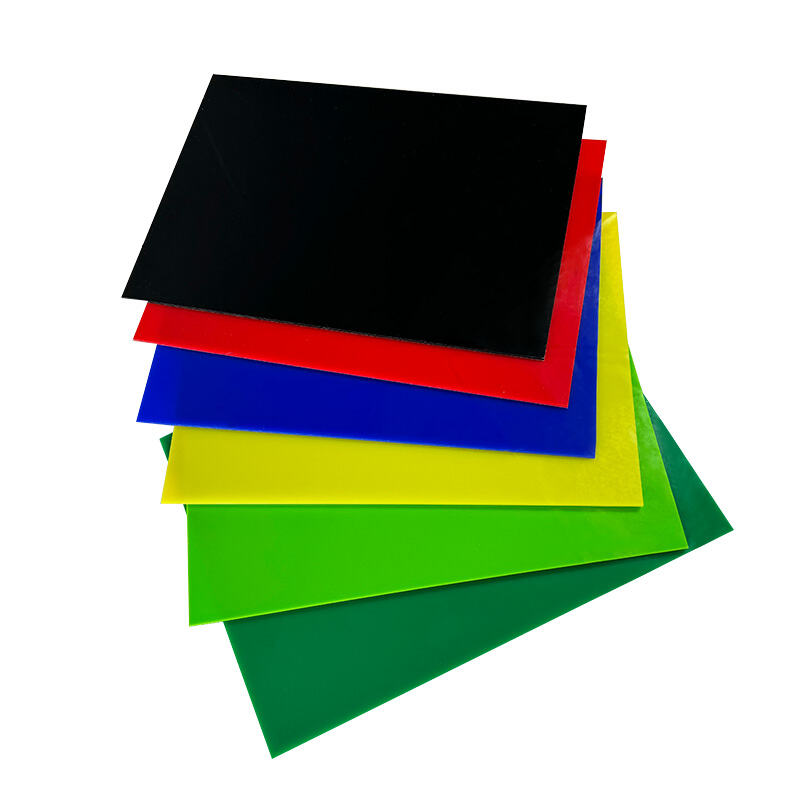

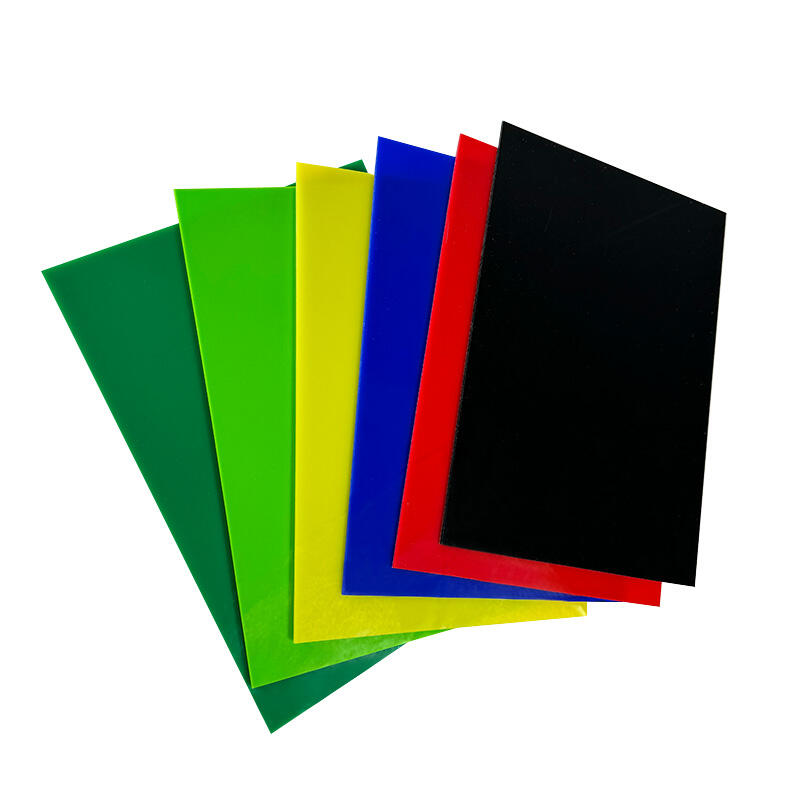

laser acrylic sheets

Laser acrylic sheets represent a revolutionary advancement in precision material processing, combining the versatility of high-quality acrylic with the extraordinary capabilities of laser technology. These specialized sheets are engineered specifically for laser cutting, engraving, and etching applications, offering unparalleled precision and exceptional results across diverse industries. The primary function of laser acrylic sheets involves providing a superior substrate that responds optimally to laser beam interactions, creating clean cuts, intricate designs, and detailed engravings without the typical issues associated with conventional acrylic materials. Technologically, these sheets incorporate advanced formulations that minimize melting, reduce flame polishing effects, and eliminate the formation of rough edges during laser processing. The molecular structure of laser acrylic sheets has been specifically optimized to absorb laser energy efficiently, resulting in smooth, professional-grade finishes that require minimal post-processing work. These materials typically feature enhanced optical clarity, superior surface quality, and consistent thickness throughout the entire sheet, ensuring predictable and repeatable results in manufacturing environments. Applications for laser acrylic sheets span numerous sectors, including signage manufacturing, architectural modeling, prototype development, decorative arts, educational displays, retail fixtures, medical device components, and electronic enclosures. The automotive industry utilizes these sheets for dashboard components and interior elements, while the aerospace sector employs them for lightweight structural components and transparent panels. In the creative industries, artists and designers leverage laser acrylic sheets for sculptural works, jewelry creation, and custom lighting solutions. The construction industry benefits from their use in architectural elements, safety barriers, and decorative panels that require precise dimensions and flawless finishes.