Versatile Design and Customization Options

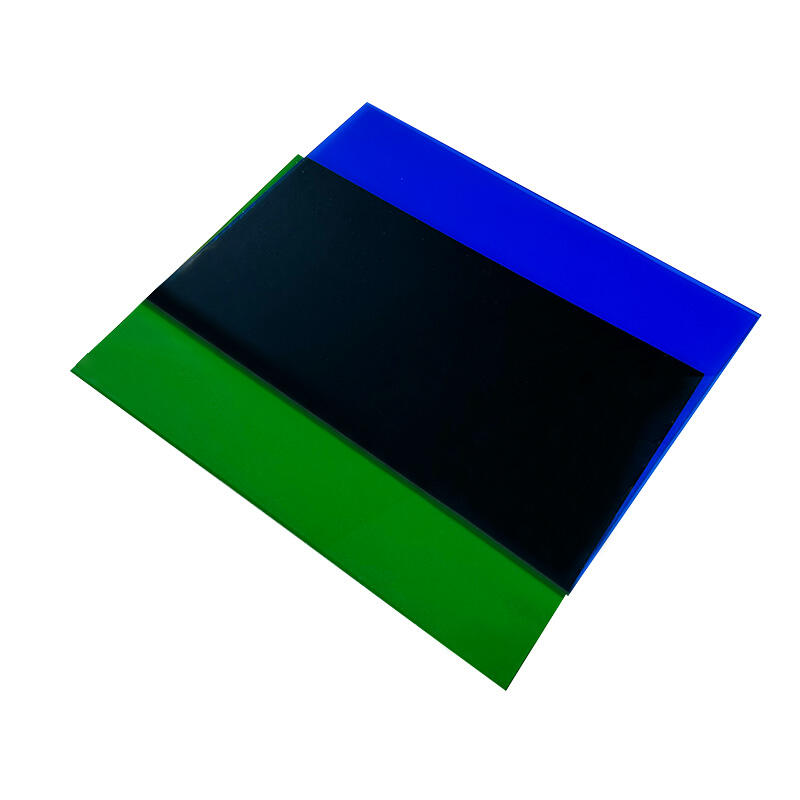

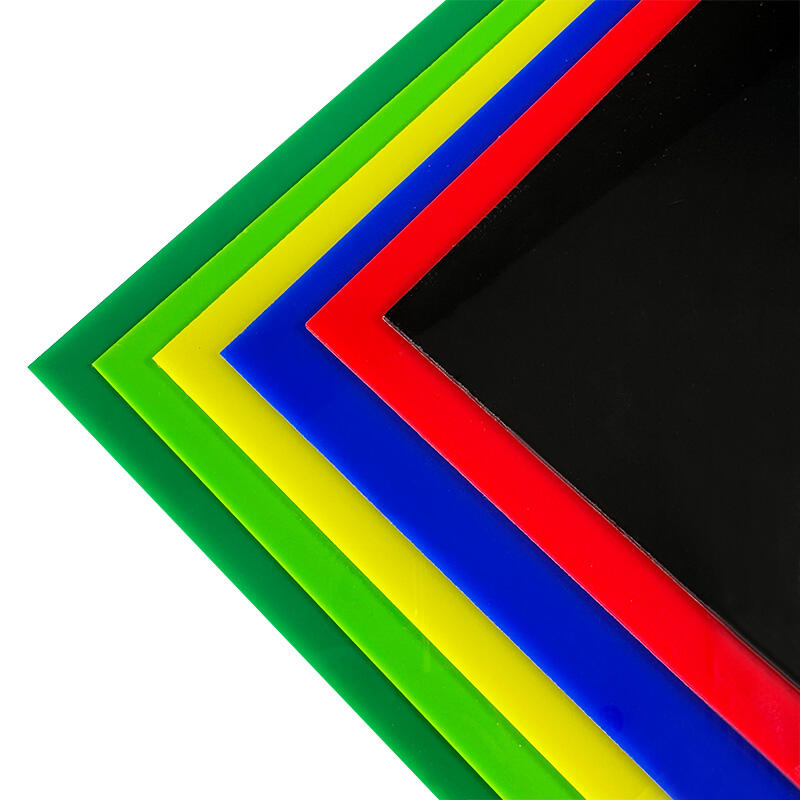

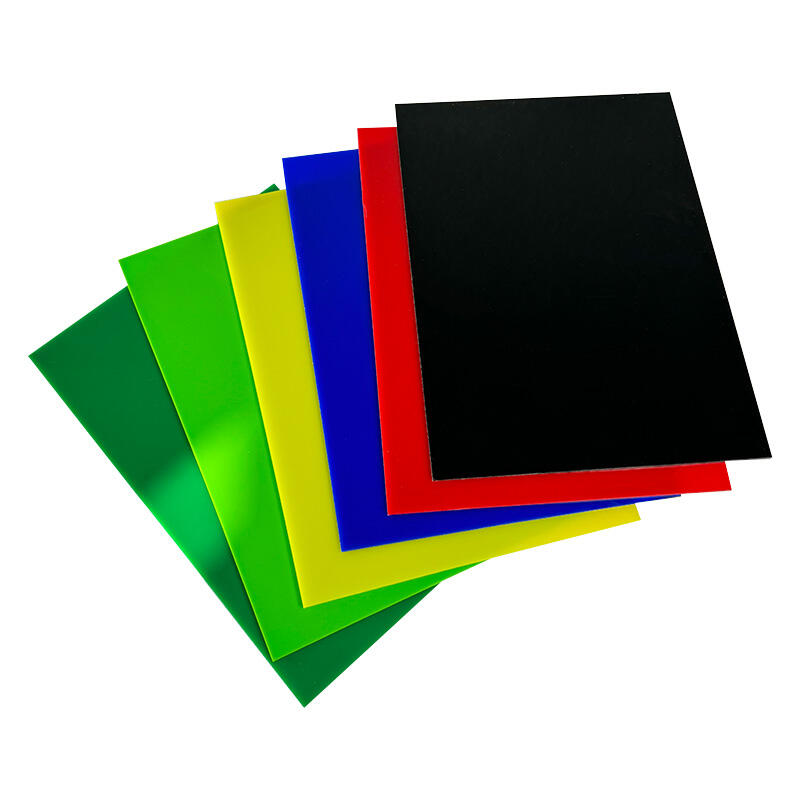

Frosted acrylic panels offer unprecedented design versatility and customization capabilities that enable architects and designers to realize complex creative visions while meeting specific functional requirements. Advanced manufacturing techniques allow for precise cutting, shaping, and forming operations that create custom profiles, curves, and geometric patterns impossible to achieve with traditional glass materials. CNC machining capabilities enable intricate decorative elements, perforations, and edge treatments that add distinctive character to any installation. Thermoforming processes allow three-dimensional shaping for curved applications, domed skylights, and architectural features that follow building contours. Color customization extends far beyond standard options through advanced tinting technologies that produce virtually any desired hue while maintaining optimal light transmission properties. Specialty finishes include varying degrees of frost intensity, from subtle texture to heavy diffusion, allowing precise control over privacy levels and aesthetic effects. Digital printing capabilities enable custom graphics, logos, and artistic designs to be permanently incorporated into the panel surface for branded environments and decorative applications. Thickness options range from thin sheets for lightweight applications to heavy panels for structural glazing systems, accommodating diverse load requirements and spanning capabilities. Edge finishing techniques include polishing, beveling, and specialized sealing methods that create professional appearances suitable for high-end architectural projects. Lamination possibilities allow multiple layers with different properties to be combined, creating composite panels with enhanced performance characteristics. Integration compatibility with standard glazing systems, curtain walls, and framing assemblies ensures seamless incorporation into existing construction methods. Custom fabrication services accommodate unique project requirements including non-standard dimensions, complex geometries, and specialty hardware integration. The material's workability allows on-site modifications when necessary, providing installation flexibility that reduces project delays and costs. Quality assurance processes ensure that custom frosted acrylic panels meet exact specifications while maintaining the superior performance characteristics of standard products.