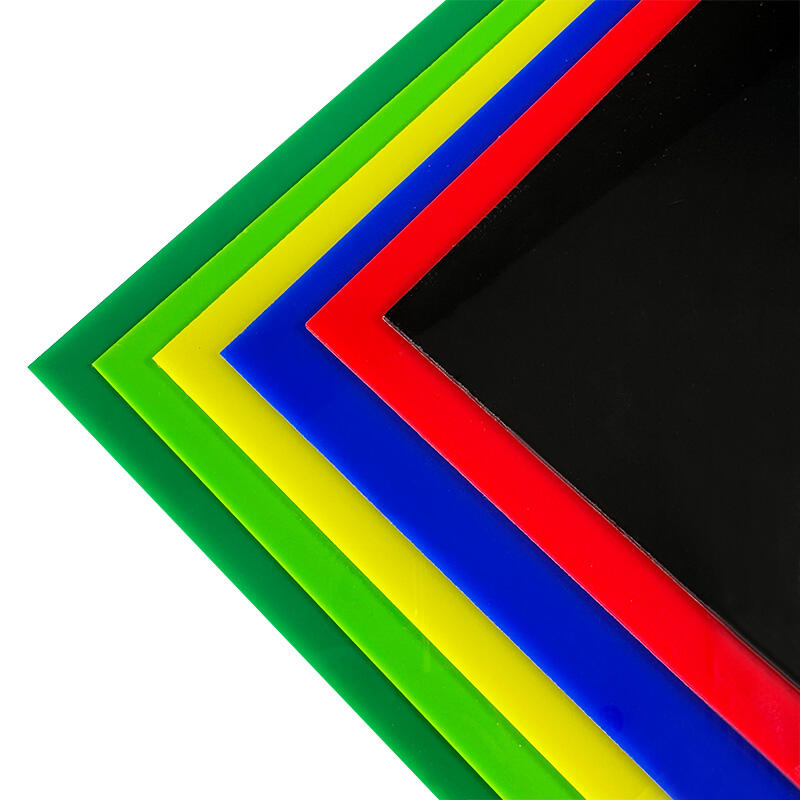

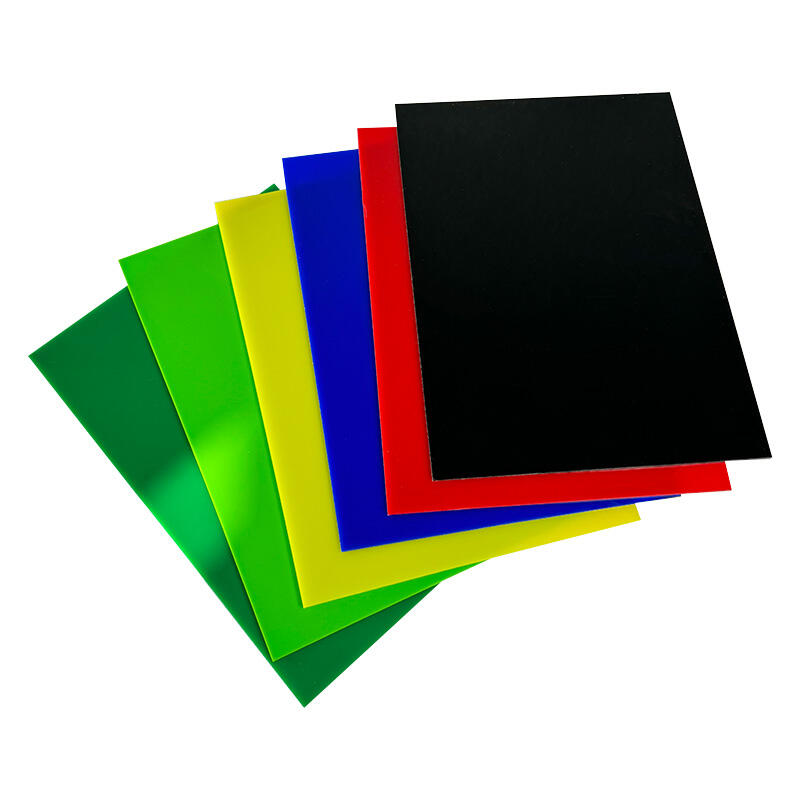

extruded acrylic sheets

Extruded acrylic sheets represent a revolutionary advancement in thermoplastic manufacturing, offering exceptional versatility and performance across numerous industrial and commercial applications. These premium-grade polymer sheets are produced through a specialized extrusion process that creates consistent thickness, superior surface quality, and outstanding optical clarity. The manufacturing technique involves heating acrylic resin to a molten state and forcing it through precision-engineered dies, resulting in continuous sheets with uniform properties throughout their structure. This production method enables manufacturers to create extruded acrylic sheets in various thicknesses, colors, and surface textures to meet diverse market requirements. The technological foundation of extruded acrylic sheets lies in their polymethyl methacrylate (PMMA) composition, which provides remarkable durability and weather resistance. These sheets maintain their structural integrity under extreme temperature fluctuations, UV exposure, and environmental stresses that would typically degrade conventional materials. The extrusion process creates a molecular structure that enhances impact resistance while preserving the material's inherent transparency and light transmission properties. Primary functions of extruded acrylic sheets include architectural glazing, protective barriers, display applications, and industrial components where clarity and strength are paramount. Their excellent machinability allows for precise cutting, drilling, and forming operations without compromising structural integrity. The material's chemical resistance makes it suitable for environments where exposure to cleaning agents, mild acids, and alkalis is common. Additionally, extruded acrylic sheets offer excellent insulation properties, contributing to energy efficiency in building applications. These sheets find extensive use in construction projects, automotive industries, signage manufacturing, furniture design, and specialized equipment where traditional glass would be impractical or unsafe.