acrylic sheet bulk order

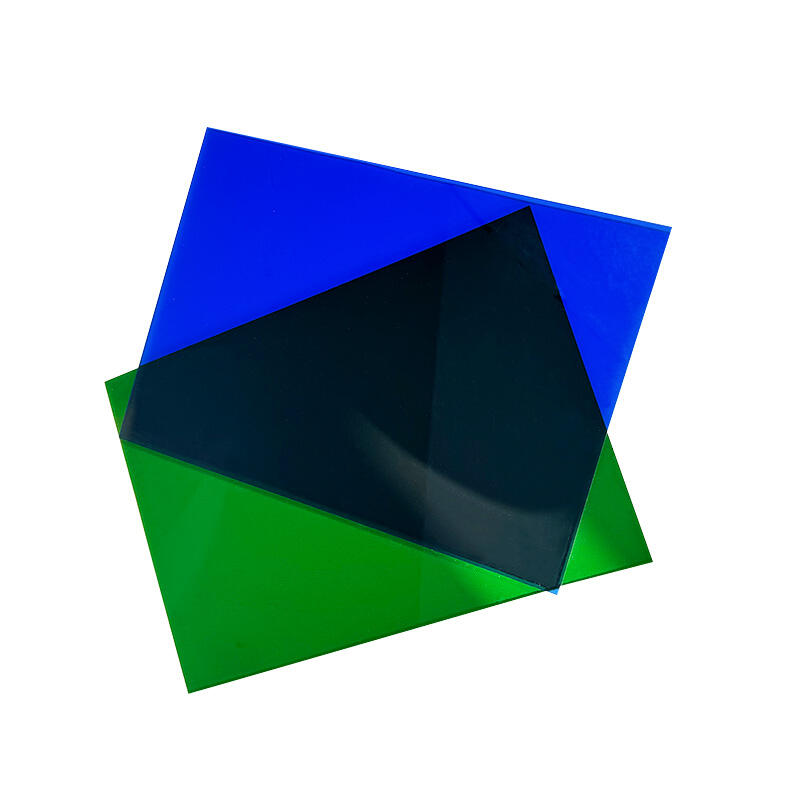

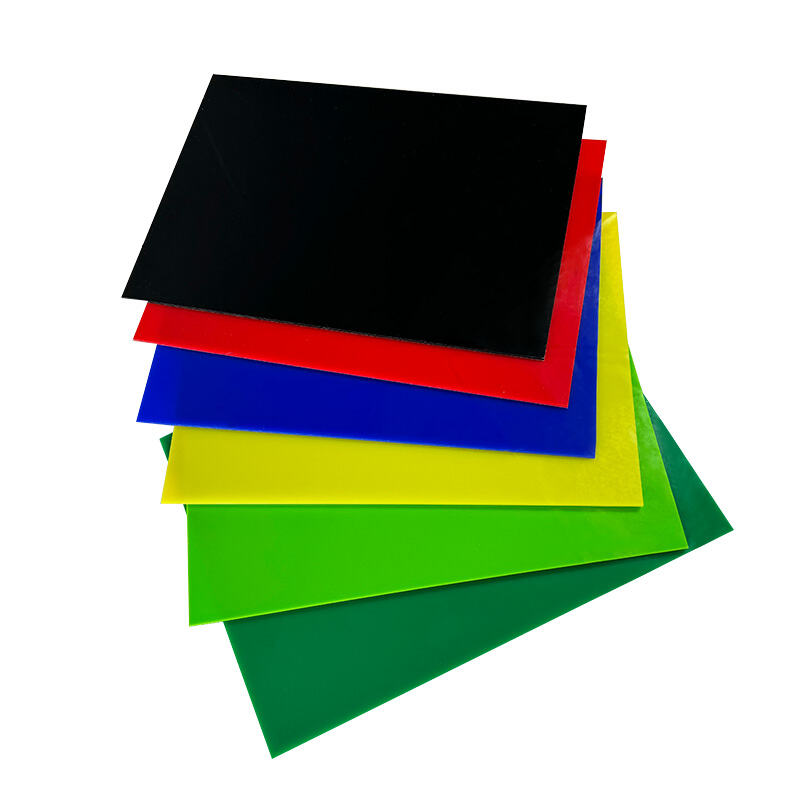

Acrylic sheet bulk order represents a comprehensive solution for businesses and organizations requiring substantial quantities of high-quality thermoplastic materials. These transparent or colored sheets serve as versatile alternatives to glass in countless applications, offering superior durability and design flexibility. The main functions of acrylic sheets in bulk orders encompass structural glazing, protective barriers, display solutions, and decorative elements across multiple industries. Technologically, acrylic sheets feature exceptional optical clarity with light transmission rates exceeding 92 percent, making them ideal for applications requiring crystal-clear visibility. The material demonstrates remarkable impact resistance, being approximately 17 times stronger than ordinary glass while weighing roughly half as much. This combination of strength and lightweight properties makes acrylic sheet bulk order particularly valuable for large-scale installations. The manufacturing process involves either cell casting or continuous casting methods, producing sheets with consistent thickness tolerance and smooth surface finish. Advanced UV stabilization technology ensures long-term performance without yellowing or degradation when exposed to sunlight. Temperature resistance ranges from -40°C to 80°C, maintaining structural integrity across diverse environmental conditions. The material exhibits excellent chemical resistance against most cleaning agents and atmospheric pollutants. Applications for acrylic sheet bulk order span architectural glazing, retail displays, museum exhibition cases, medical equipment housings, automotive components, and marine applications. In architecture, these sheets create stunning facades, skylights, and interior partitions. Retail environments utilize them for product displays, point-of-sale materials, and protective screens. The signage industry relies heavily on acrylic sheets for illuminated signs, outdoor advertising panels, and wayfinding systems. Educational institutions incorporate them into laboratory equipment, safety barriers, and interactive displays. The food service sector employs acrylic sheets for sneeze guards, display cases, and hygienic barriers. Manufacturing facilities use them for machine guards, viewing windows, and cleanroom partitions. The versatility of acrylic sheet bulk order makes it indispensable across numerous sectors requiring reliable, transparent, and durable materials.