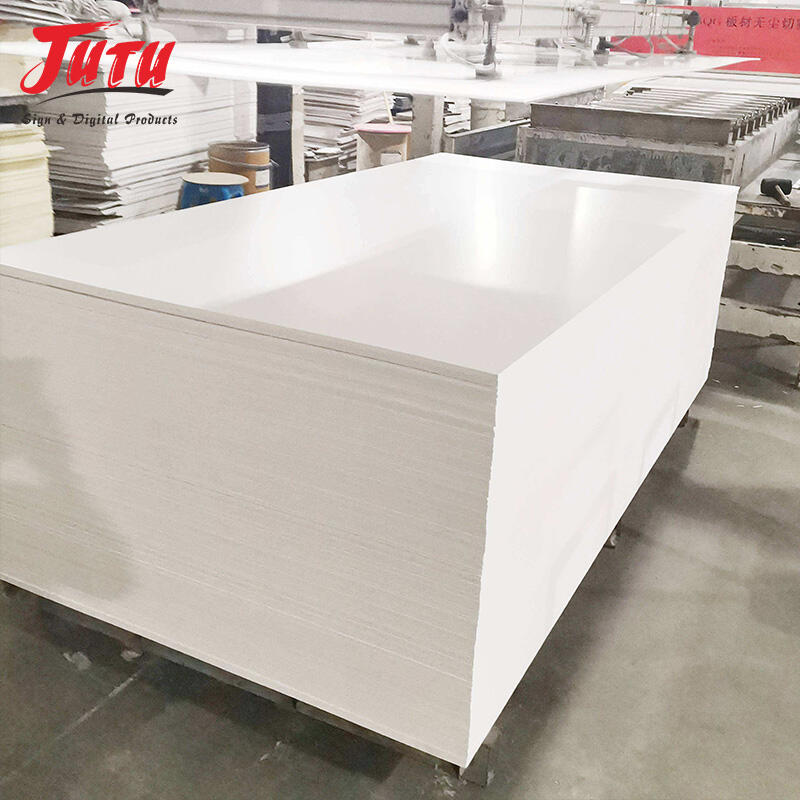

Outstanding Moisture and Chemical Resistance Performance

Foamed PVC panels excel in environments where moisture exposure and chemical contact pose significant challenges to conventional building materials. The closed-cell foam structure prevents water absorption entirely, eliminating the swelling, warping, and degradation commonly experienced with wood-based products or porous materials. This moisture resistance extends beyond simple water repellency to include protection against humidity, steam, and prolonged exposure to wet conditions without any deterioration in structural properties or appearance. The chemical composition of PVC provides inherent resistance to a wide range of aggressive substances including acids, alkalis, salts, and organic solvents that would rapidly damage metal, wood, or composite alternatives. This chemical resistance makes foamed PVC panels ideal for industrial environments, laboratories, food processing facilities, and marine applications where chemical exposure is routine. The panels maintain their integrity when exposed to cleaning chemicals, disinfectants, and sanitizing agents commonly used in healthcare, food service, and manufacturing facilities. Unlike metal panels that may corrode or wood products that can rot when exposed to moisture and chemicals, foamed PVC panels retain their original properties indefinitely under these challenging conditions. The smooth, non-porous surface prevents bacterial growth and contamination, making these panels suitable for applications requiring high hygiene standards. Coastal environments with salt spray and high humidity pose no threat to foamed PVC panels, unlike steel or aluminum that may corrode over time. The material resists staining from spills, chemicals, or environmental pollutants, maintaining clean appearances without special treatments or protective coatings. This resistance extends to UV radiation, preventing the color fading and brittleness that affects some plastics under prolonged sun exposure. The combination of moisture and chemical resistance eliminates the need for protective finishes, sealers, or periodic refinishing that adds ongoing maintenance costs to other materials. These properties make foamed PVC panels particularly valuable in swimming pool areas, shower facilities, commercial kitchens, and other high-moisture environments where material reliability is essential for long-term performance and safety.