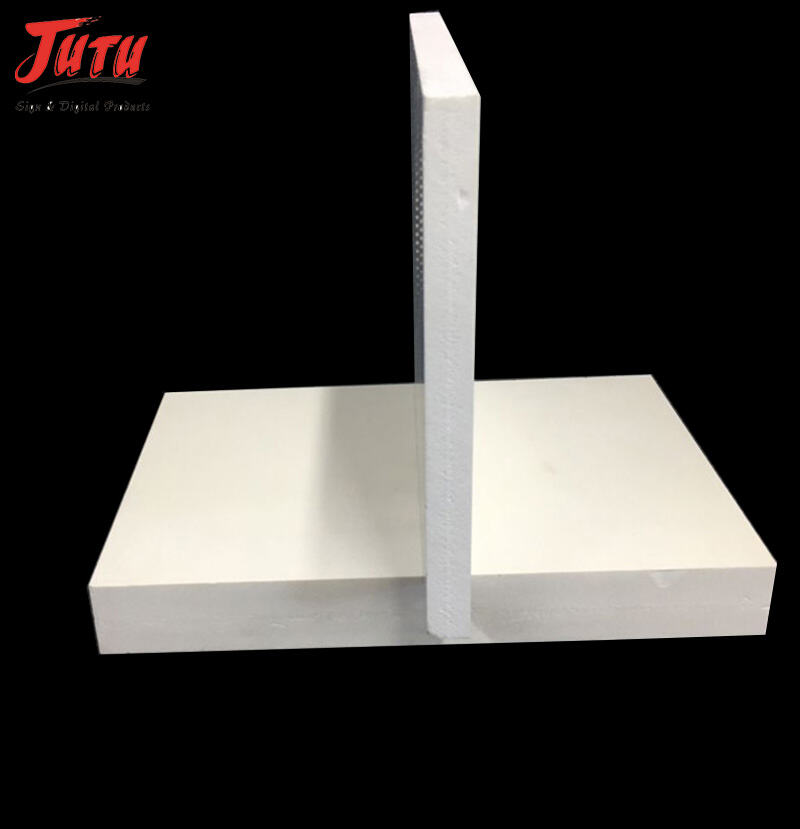

Superior Workability and Fabrication Flexibility

The celtec board revolutionizes manufacturing and fabrication processes through its superior workability and exceptional fabrication flexibility, enabling designers and manufacturers to achieve complex geometries and precise specifications with unprecedented ease. This advanced material responds beautifully to standard woodworking tools, allowing fabricators to cut, route, drill, and shape the board using existing equipment without requiring specialized tooling or extensive operator training. The uniform density distribution throughout the celtec board ensures consistent cutting performance, eliminating the tear-out and chipping commonly experienced with wood grain variations or composite materials. Edge finishing becomes effortless, as the material machines to smooth, clean edges that require minimal post-processing, significantly reducing production time and labor costs. The board's thermal forming capabilities open new design possibilities, allowing manufacturers to create curved surfaces, complex profiles, and three-dimensional shapes through controlled heating and forming processes. This thermoplastic behavior enables the creation of seamless corners and integrated features that would require multiple components and joining operations with traditional materials. Bonding versatility represents another significant advantage, as the celtec board accepts various adhesives, mechanical fasteners, and welding techniques, providing fabricators with multiple joining options to suit specific application requirements. Surface preparation requirements are minimal, with the board's smooth, uniform texture accepting paints, laminates, vinyl graphics, and other finishes without extensive priming or surface treatment. The material's dimensional stability during processing prevents the warping and distortion that can occur with natural wood products, ensuring consistent results and reducing waste from rejected parts. Machining efficiency improves dramatically due to the board's consistent cutting forces and chip evacuation characteristics, allowing for higher feed rates and improved surface finishes. The absence of grain structure eliminates directional cutting preferences, enabling optimized nesting patterns that maximize material utilization and minimize waste generation.