acrylic mirror sheet price

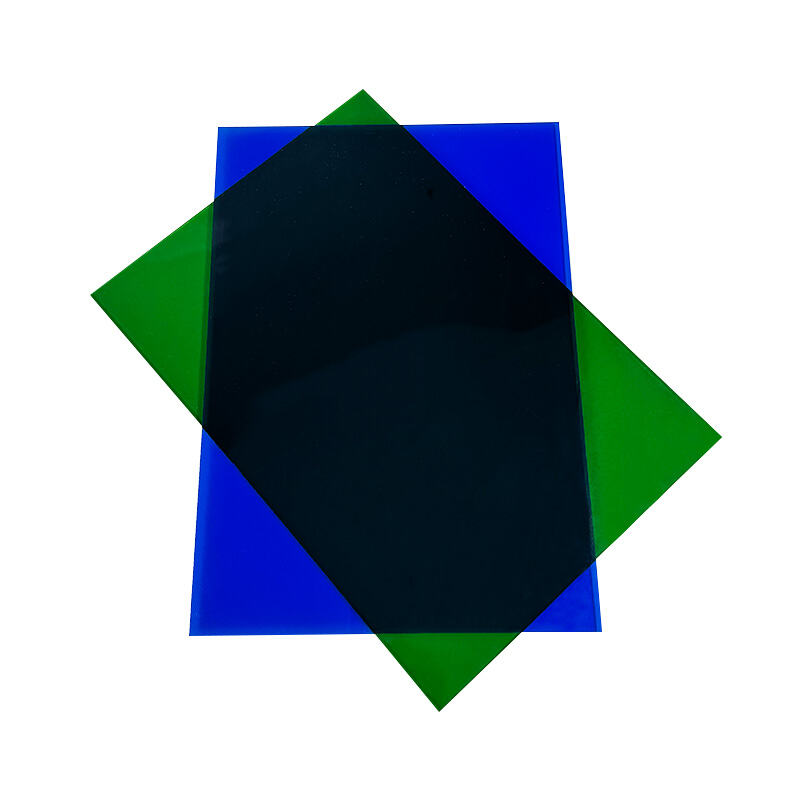

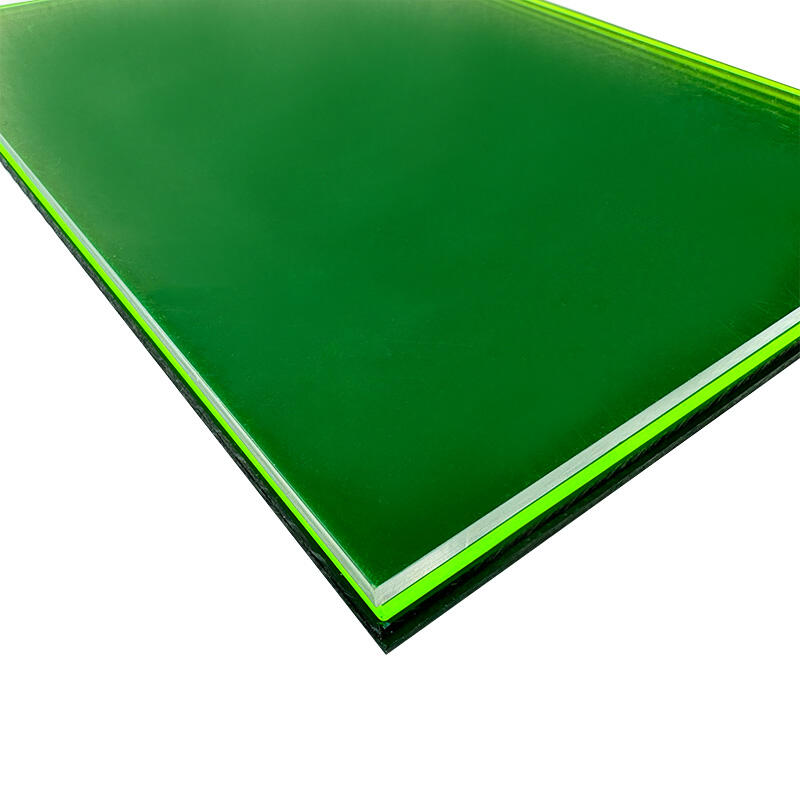

The acrylic mirror sheet price represents exceptional value in the modern materials market, offering a cost-effective alternative to traditional glass mirrors across numerous industries. These innovative sheets combine the reflective properties of conventional mirrors with the enhanced durability and versatility of high-grade acrylic materials. Understanding acrylic mirror sheet price factors helps customers make informed purchasing decisions while maximizing their investment returns. The main functions of acrylic mirror sheets extend far beyond simple reflection, encompassing decorative applications, safety implementations, and specialized industrial uses. Their lightweight construction reduces installation costs and structural requirements, making the acrylic mirror sheet price even more attractive for large-scale projects. Technological features include advanced optical clarity that rivals traditional glass, superior impact resistance that prevents shattering, and UV-stable formulations that maintain reflective quality over extended periods. The manufacturing process utilizes specialized coating techniques that bond reflective materials directly to acrylic substrates, ensuring long-lasting performance and consistent quality standards. Applications span residential, commercial, and industrial sectors, including bathroom fixtures, retail displays, gymnasium installations, therapeutic environments, and architectural elements. The acrylic mirror sheet price varies based on thickness specifications, surface treatments, protective coatings, and custom sizing requirements. Standard thicknesses range from 1mm to 6mm, with specialized applications requiring custom dimensions that influence overall pricing structures. Quality grades affect acrylic mirror sheet price considerations, with premium options offering enhanced optical performance and extended warranty coverage. Installation versatility reduces labor costs, as these sheets can be cut, drilled, and shaped using standard tools without specialized equipment requirements. Weather resistance properties make them suitable for outdoor applications where traditional mirrors would fail, expanding their utility and justifying the acrylic mirror sheet price investment.