aluminum composite panel cost

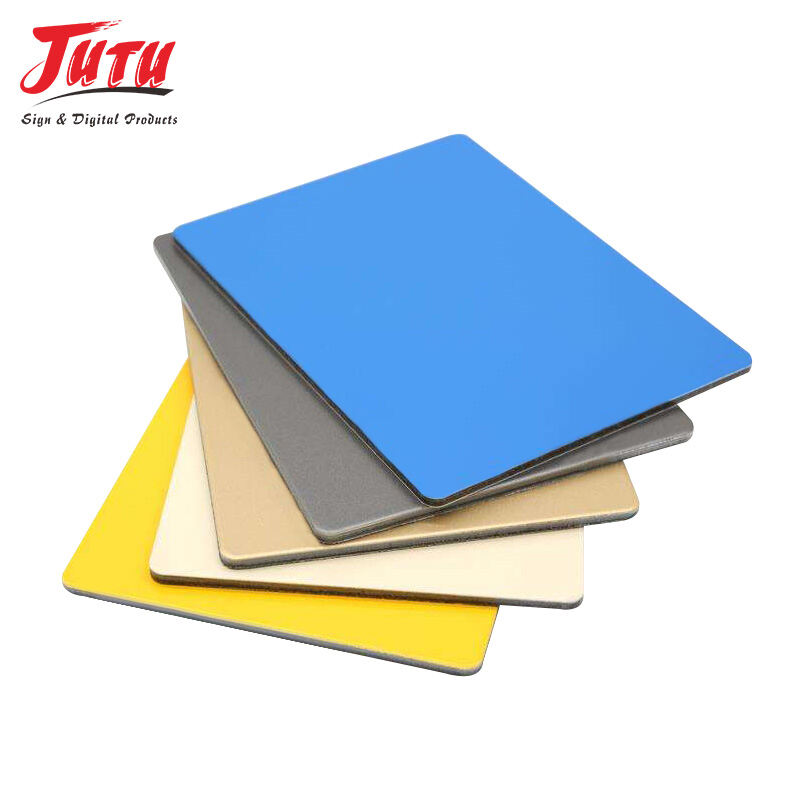

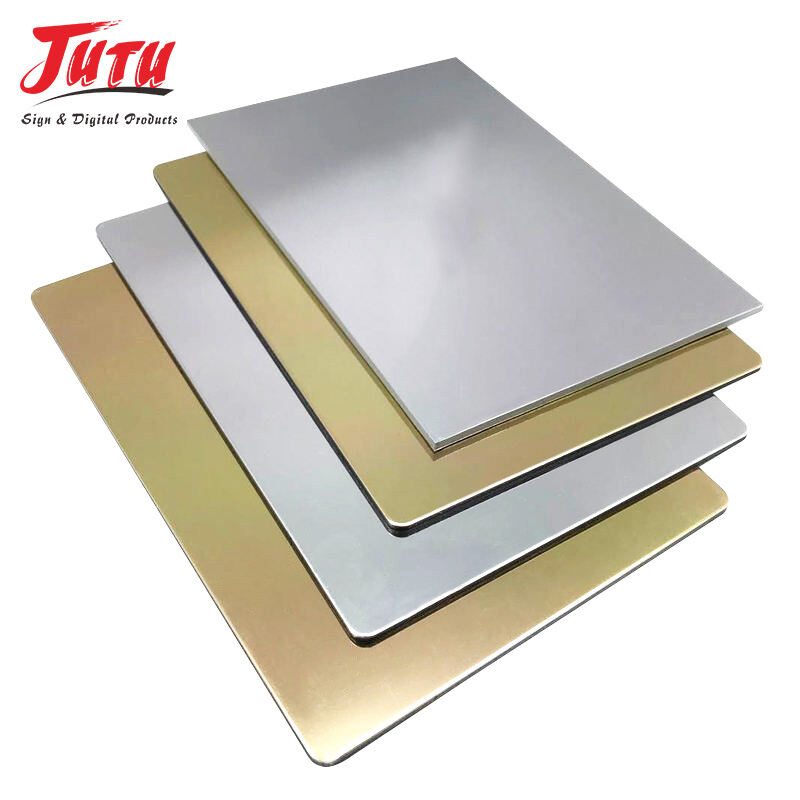

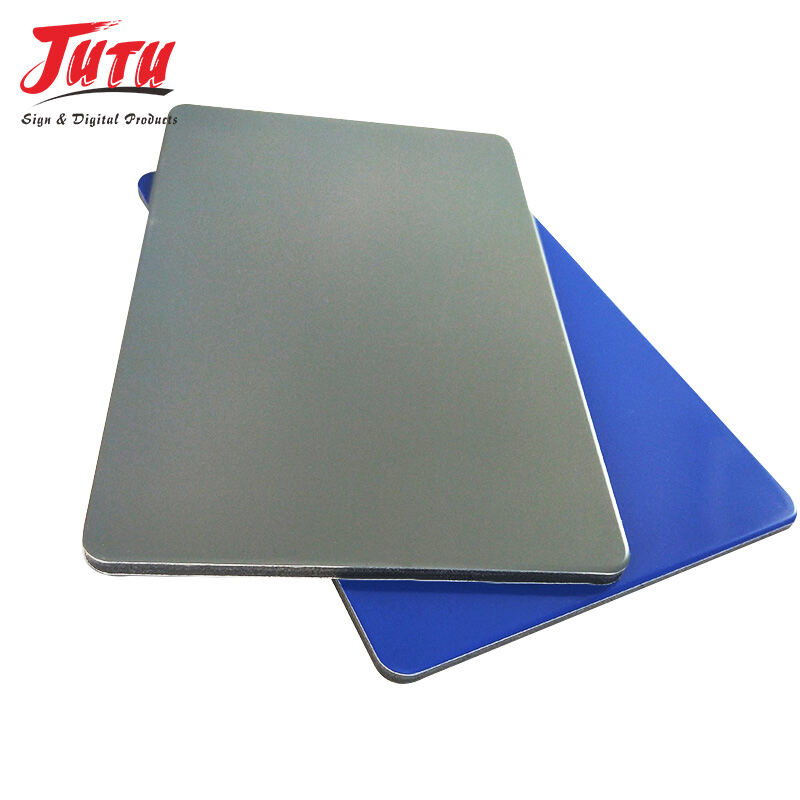

Understanding aluminum composite panel cost is essential for making informed decisions in modern construction and architectural projects. These innovative building materials consist of two aluminum sheets bonded to a non-aluminum core, typically made from polyethylene or mineral-filled materials. The aluminum composite panel cost varies significantly based on factors such as thickness, surface finish, brand reputation, and order quantity. Standard panels range from 3mm to 6mm in thickness, with specialized applications requiring custom dimensions that affect the overall aluminum composite panel cost structure. The primary functions of these panels include exterior cladding, interior decoration, signage applications, and curtain wall systems. Their lightweight nature reduces structural load requirements while maintaining exceptional durability and weather resistance. Technological features that influence aluminum composite panel cost include advanced coating systems, fire-resistant core materials, and precision manufacturing processes that ensure consistent quality and performance. The panels offer superior flatness, excellent formability, and outstanding color retention properties that justify their aluminum composite panel cost investment. Applications span across commercial buildings, residential developments, industrial facilities, and transportation infrastructure projects. The aluminum composite panel cost becomes more economical when considering their longevity, minimal maintenance requirements, and energy efficiency benefits. Modern manufacturing techniques have streamlined production processes, making aluminum composite panel cost more competitive compared to traditional building materials. Quality certifications and compliance with international standards also impact the aluminum composite panel cost, ensuring projects meet safety and performance requirements. Installation efficiency contributes to overall project economics, as these panels reduce labor costs through simplified mounting systems and faster installation procedures.