Exceptional Design Flexibility and Aesthetic Appeal

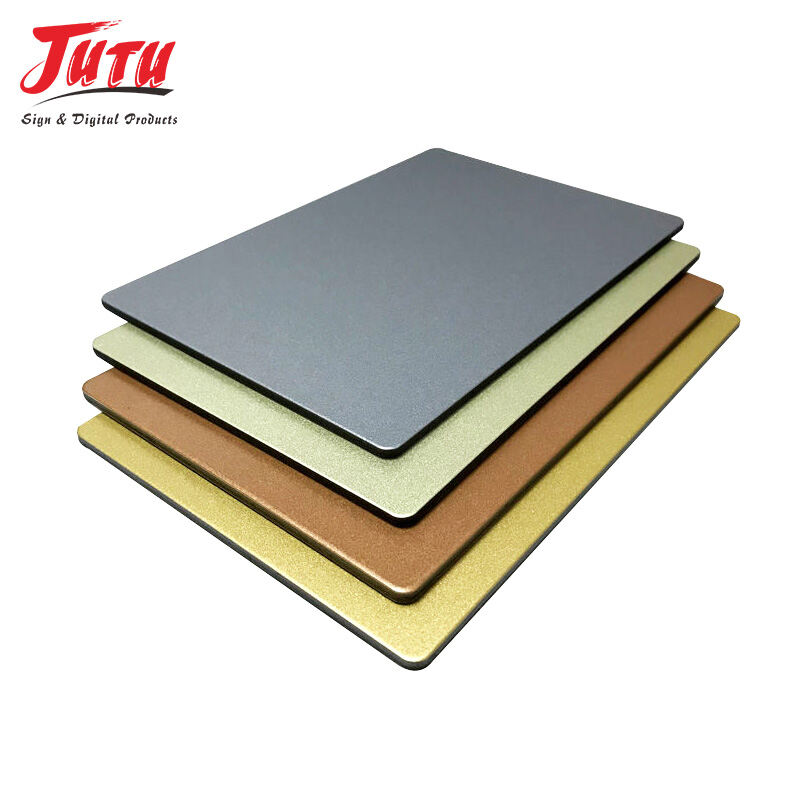

The design versatility of aluminium plastic board opens unlimited creative possibilities for architects, designers, and building owners seeking distinctive architectural solutions. This remarkable flexibility begins with the material's ability to form complex curves and shapes that would be impossible or prohibitively expensive with traditional materials. The aluminium plastic board can be bent, folded, and shaped during installation without cracking or losing structural integrity, enabling dramatic architectural effects and flowing design elements. Surface finishing options provide extraordinary customization capabilities, including wood grain textures that replicate expensive hardwoods, brushed metal effects, mirror finishes, and virtually unlimited color combinations. Advanced printing technologies allow custom graphics, corporate logos, and artistic designs to be permanently applied to aluminium plastic board surfaces, creating unique branding opportunities and decorative elements. The material's lightweight properties enable designers to implement bold cantilevers, overhangs, and suspended elements that would require extensive structural support with heavier materials. Modular panel systems facilitate complex geometric patterns, mixing different colors and textures within single installations for striking visual impact. The aluminium plastic board accepts various mounting methods, from traditional mechanical fasteners to concealed clip systems that create seamless, uninterrupted surfaces. Architects appreciate how the material integrates with other building systems, including glazing, stone, and conventional cladding materials for sophisticated mixed-media facades. Interior applications benefit from the same design flexibility, with aluminium plastic board serving as accent walls, ceiling systems, and decorative panels that enhance commercial and residential spaces. The material's dimensional stability ensures that complex installations maintain their intended appearance over time without warping, buckling, or shifting. Custom fabrication services enable project-specific solutions, including pre-formed panels, integrated mounting systems, and precision-cut openings for windows, doors, and mechanical equipment. Design professionals consistently choose aluminium plastic board when projects demand both aesthetic excellence and practical performance in challenging applications.