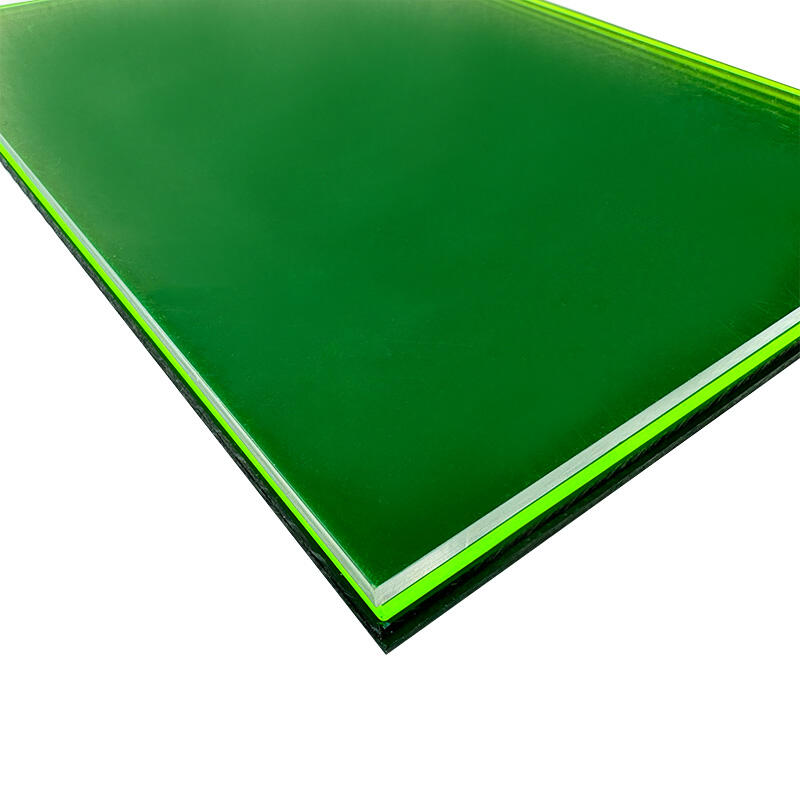

acrylic sheet for furniture

Acrylic sheet for furniture represents a revolutionary material that transforms modern interior design through its exceptional versatility and performance characteristics. This thermoplastic polymer material, scientifically known as polymethyl methacrylate (PMMA), offers furniture manufacturers and designers an innovative alternative to traditional materials like glass, wood, and metal. The acrylic sheet for furniture combines optical clarity with remarkable durability, creating possibilities for contemporary furniture pieces that seamlessly blend functionality with aesthetic appeal. Manufacturing processes involve advanced polymerization techniques that ensure consistent quality and dimensional stability throughout each sheet. The material's molecular structure provides excellent resistance to UV radiation, preventing yellowing and maintaining crystal-clear transparency over extended periods. Temperature resistance capabilities allow acrylic sheet for furniture to withstand typical household conditions without warping or degradation. Surface treatments enhance scratch resistance while maintaining the material's inherent smoothness and brilliance. Technological innovations in acrylic sheet for furniture production include specialized forming processes that enable complex curved shapes and intricate designs previously impossible with conventional materials. The material accepts various finishing techniques, from polishing to texturing, allowing designers unlimited creative expression. Fabrication methods encompass cutting, drilling, bonding, and thermoforming, providing complete manufacturing flexibility for furniture applications. Quality control measures ensure each acrylic sheet for furniture meets stringent standards for optical clarity, mechanical strength, and dimensional accuracy. Environmental considerations include recyclability features that support sustainable furniture production practices. The material's lightweight properties reduce transportation costs while simplifying installation procedures. Chemical resistance protects against common household cleaners and environmental factors. Applications span residential and commercial furniture segments, including display cases, shelving units, table surfaces, cabinet doors, decorative panels, and architectural elements that require both strength and visual appeal in modern living spaces.