acp composite panel

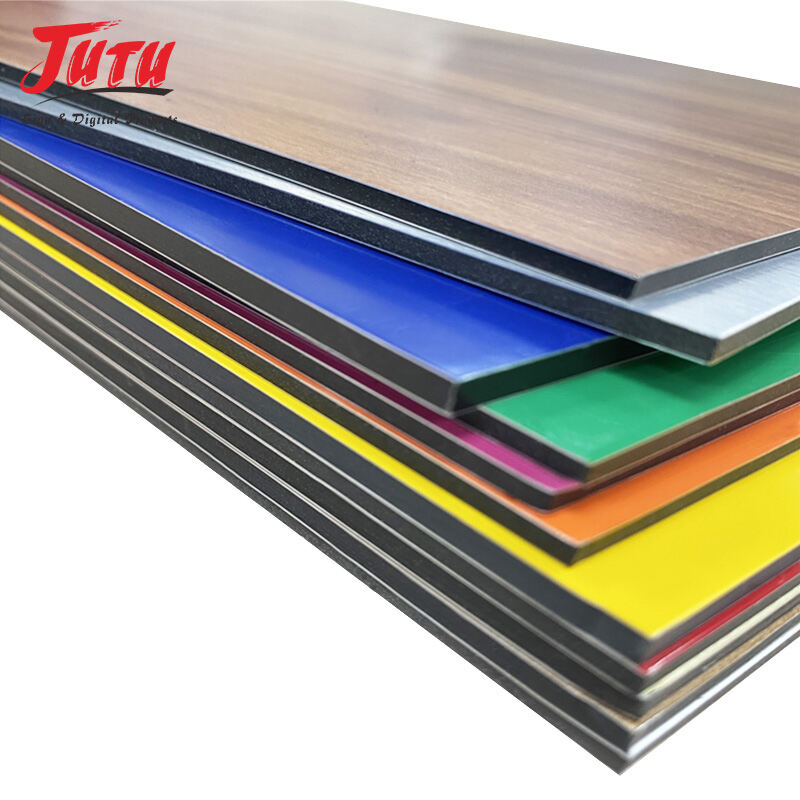

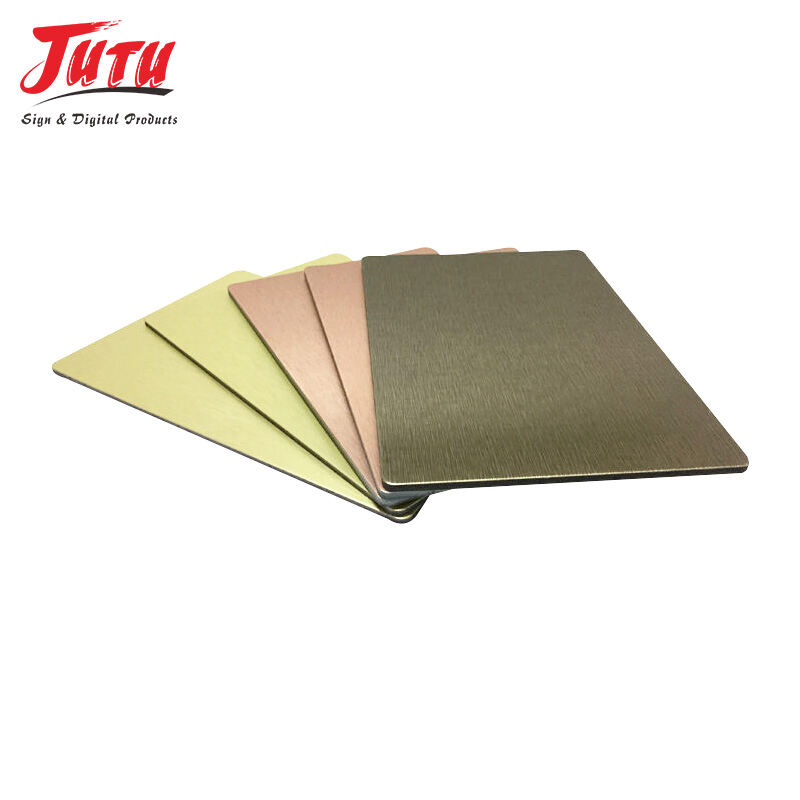

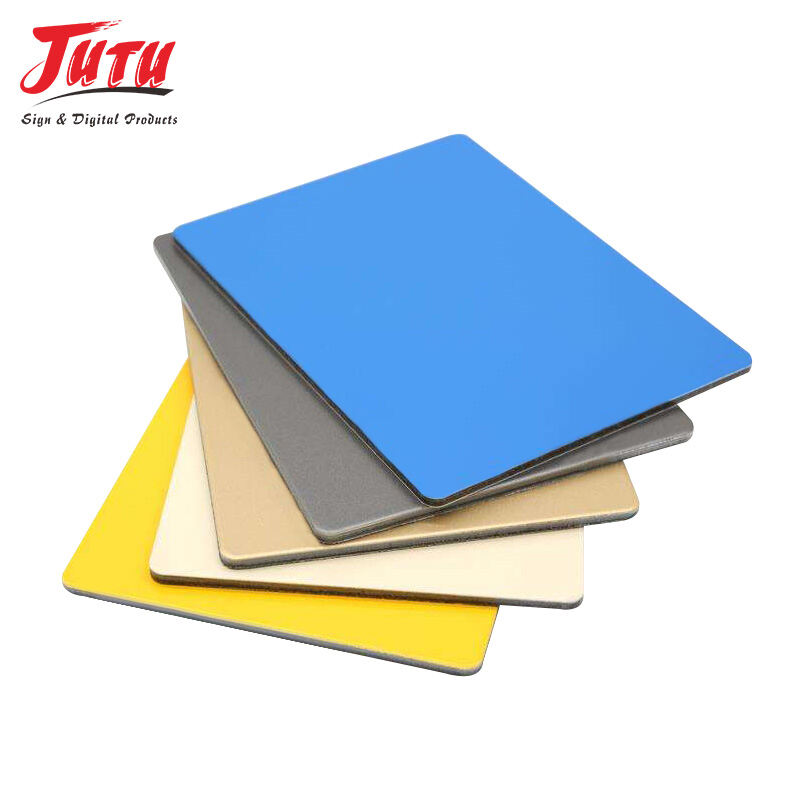

The ACP composite panel, also known as Aluminum Composite Panel, represents a revolutionary building material that has transformed modern construction and architectural design. This innovative panel consists of two thin aluminum sheets bonded to a non-aluminum core, typically made from polyethylene, mineral-filled core, or fire-retardant materials. The ACP composite panel delivers exceptional performance through its unique three-layer sandwich construction, combining the strength and durability of aluminum with the lightweight properties of the core material. The manufacturing process involves continuous lamination under controlled temperature and pressure, ensuring consistent quality and superior bonding between layers. These panels typically measure 3-6mm in thickness, with aluminum skins ranging from 0.2-0.5mm, providing optimal balance between structural integrity and weight efficiency. The core material contributes significantly to the panel's thermal and acoustic insulation properties while maintaining dimensional stability across varying environmental conditions. ACP composite panel technology incorporates advanced surface treatments including PVDF coating, polyester coating, and anodizing processes that enhance weather resistance, color retention, and surface durability. The panels exhibit excellent flatness characteristics, with minimal thermal expansion coefficients that prevent warping and buckling under temperature fluctuations. Installation versatility remains a key technological feature, as the ACP composite panel can be easily cut, bent, and shaped using standard metalworking tools, accommodating complex architectural geometries and design requirements. The material demonstrates superior resistance to corrosion, UV radiation, and chemical exposure, making it suitable for both interior and exterior applications. Primary applications include curtain wall systems, building facades, interior wall cladding, ceiling systems, signage solutions, and industrial enclosures. The ACP composite panel serves commercial buildings, residential developments, retail spaces, hospitals, educational facilities, and transportation infrastructure projects worldwide.