pvc board shop

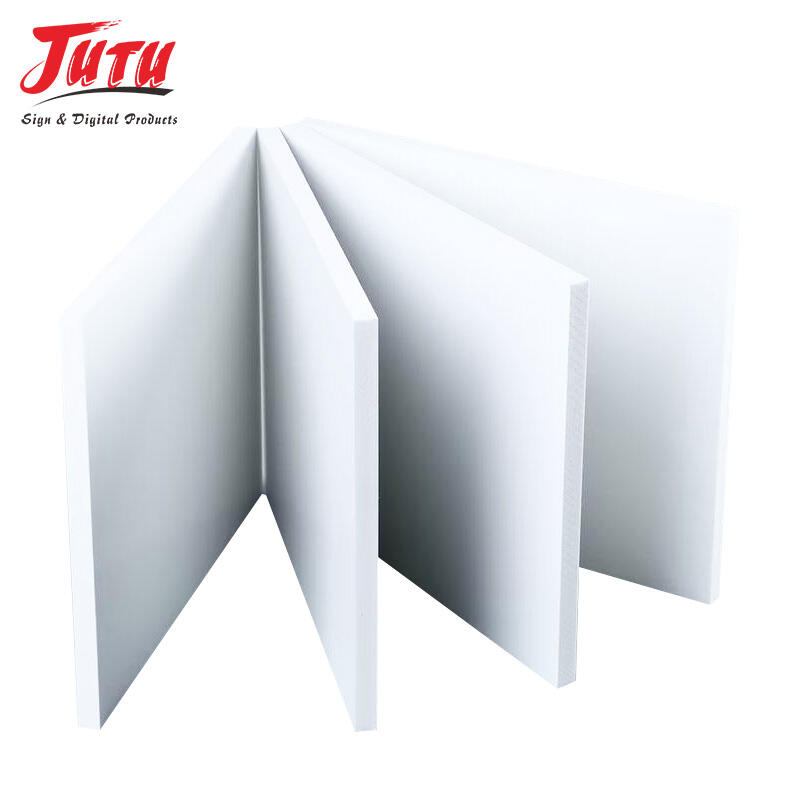

A pvc board shop represents a specialized retail establishment dedicated to providing comprehensive solutions for polyvinyl chloride board materials and related services. These establishments serve as essential hubs for construction professionals, DIY enthusiasts, and commercial clients seeking high-quality PVC board products for various applications. The modern pvc board shop combines traditional retail elements with advanced technological capabilities, offering customers access to precision cutting services, custom fabrication, and expert consultation. The primary function of a pvc board shop extends beyond simple product sales, encompassing material processing, technical advisory services, and project support. These shops typically maintain extensive inventories of PVC boards in multiple thicknesses, colors, and grades to meet diverse customer requirements. The technological infrastructure of a contemporary pvc board shop includes computer-controlled cutting systems, edge finishing equipment, and quality control mechanisms that ensure precise specifications. Advanced shops integrate digital measuring tools, CAD software compatibility, and automated inventory management systems to streamline operations and enhance customer service. The application scope for pvc board shop services spans residential construction, commercial architecture, marine projects, signage production, and industrial manufacturing. These versatile establishments cater to professionals requiring waterproof materials, chemical-resistant surfaces, and lightweight structural components. The pvc board shop environment typically features organized display areas where customers can examine material samples, compare different product grades, and visualize potential applications. Many shops provide on-site consultation services, helping customers select appropriate materials based on specific project requirements, environmental conditions, and budget constraints. The integration of digital technologies enables modern pvc board shop operations to offer precise quotations, project timelines, and material optimization recommendations, making them valuable partners in construction and renovation projects.