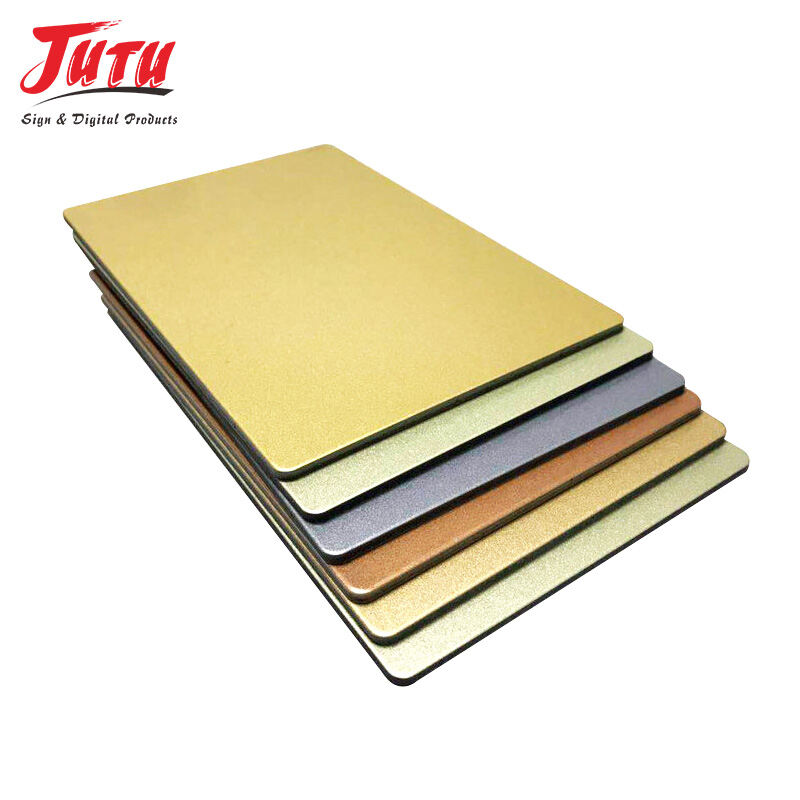

alucobond aluminium composite panel

The alucobond aluminium composite panel represents a revolutionary advancement in modern construction materials, combining innovative engineering with practical functionality to deliver exceptional performance across diverse architectural applications. This sophisticated building material consists of two thin aluminum sheets bonded to a thermoplastic core, creating a lightweight yet remarkably durable composite structure that has transformed contemporary facade design and interior applications worldwide. The alucobond aluminium composite panel showcases exceptional versatility through its unique three-layer construction, where the outer aluminum skins provide strength and weather resistance while the polyethylene core ensures optimal flexibility and impact resistance. Manufacturing processes employ advanced lamination techniques that permanently bond these components under controlled pressure and temperature conditions, resulting in a homogeneous panel with superior structural integrity. The technological features of the alucobond aluminium composite panel include excellent flatness characteristics, dimensional stability across temperature variations, and outstanding resistance to environmental factors including UV radiation, moisture, and thermal cycling. These panels demonstrate remarkable formability, allowing architects and designers to create complex curved surfaces and innovative geometric shapes that would be challenging or impossible with traditional materials. Installation processes benefit from the lightweight nature of the alucobond aluminium composite panel, reducing structural load requirements and simplifying mounting procedures while maintaining exceptional strength-to-weight ratios. Applications span commercial buildings, residential projects, transportation infrastructure, signage systems, and interior design elements where aesthetic appeal must combine with functional performance. The fire-resistant variants of alucobond aluminium composite panel meet stringent building codes and safety regulations, incorporating mineral-filled cores that provide enhanced fire protection for high-rise applications and critical infrastructure projects where safety remains paramount throughout the building lifecycle.