Kemampuan Pekerjaan dan Keluwesan Pengolahan yang Luar Biasa

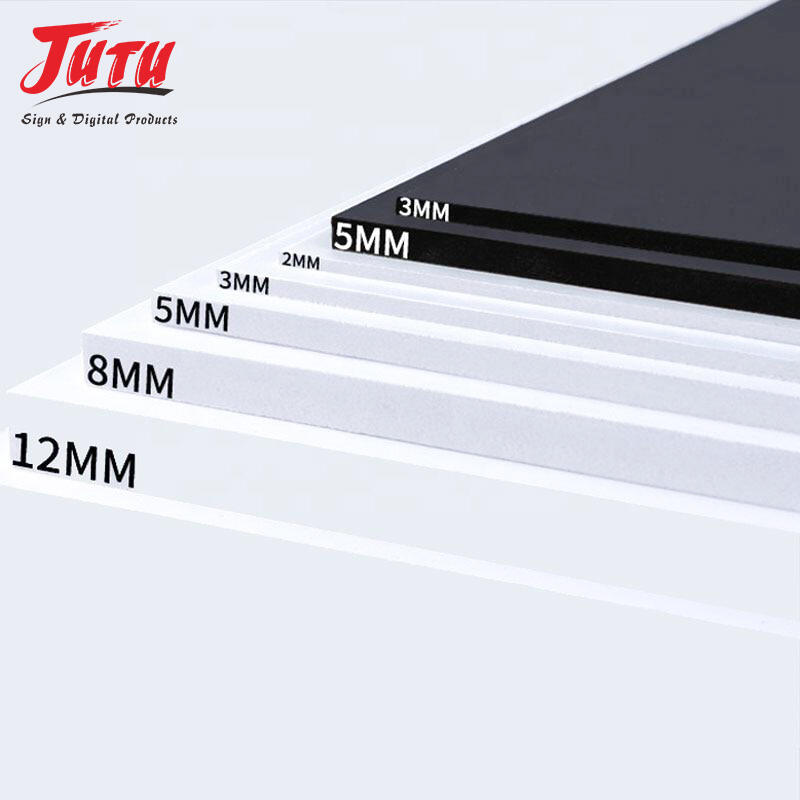

Papan busa PVC sabri menunjukkan karakteristik kerja yang luar biasa sehingga merevolusi proses fabrikasi di berbagai industri, menawarkan kemudahan penanganan dan fleksibilitas pemrosesan yang belum pernah ada sebelumnya. Material ini dapat dipotong, dibentuk, digerinda, dan dimesin menggunakan peralatan pertukangan standar, menghilangkan kebutuhan akan alat khusus atau modifikasi peralatan mahal. Struktur seluler yang seragam memastikan kinerja pemotongan yang konsisten tanpa terjadi pengelupasan, pecah rambut, atau robekan yang umum terjadi pada material komposit atau produk kayu rekayasa. Para pelaku fabrikasi profesional menghargai bagaimana papan busa PVC sabri tetap menjaga tepian yang bersih dan presisi selama operasi pemotongan, baik menggunakan gergaji bundar, gergaji pita, maupun router CNC, menghasilkan hasil akhir berkualitas profesional tanpa perlu perawatan tepi tambahan. Kemampuan termobentuk yang sangat baik memungkinkan bentuk lengkung kompleks dan bentuk tiga dimensi ketika dipanaskan pada suhu yang sesuai, memperluas kemungkinan desain untuk elemen arsitektural, rambu, dan perlengkapan khusus. Operasi pengeboran menghasilkan lubang yang bersih tanpa retak atau delaminasi, sementara kepadatan material memberikan daya pegangan yang sangat baik untuk pengikat mekanis termasuk sekrup, baut, dan perkakas khusus. Papan busa PVC sabri menerima berbagai perlakuan permukaan termasuk pengecatan, laminasi, pencetakan, dan tekstur, memungkinkan kustomisasi estetika tanpa batas untuk memenuhi kebutuhan proyek tertentu. Perekatan lem bekerja sangat baik pada papan busa PVC sabri, menciptakan sambungan permanen dengan lem struktural, semen kontak, atau agen perekat khusus yang kompatibel dengan busa. Toleransi ketebalan yang konsisten dan geometri permukaan yang datar pada material ini menghilangkan pekerjaan persiapan yang diperlukan pada material tidak rata atau melengkung, mengurangi waktu fabrikasi dan meningkatkan kualitas produk akhir. Teknik pengelasan panas menciptakan sambungan tanpa jahitan untuk aplikasi yang membutuhkan permukaan kontinu atau sambungan tahan air, sangat bernilai dalam konstruksi tangki, penahanan kimia, atau aplikasi kelautan. Kompatibilitas papan busa PVC sabri dengan sistem cetak digital dan potong digital memungkinkan prototipe cepat dan fabrikasi khusus untuk produksi jumlah sedikit atau kebutuhan desain unik, mendukung aplikasi inovatif dalam display, elemen arsitektural, dan komponen khusus.