produsen lembaran akrilik besar

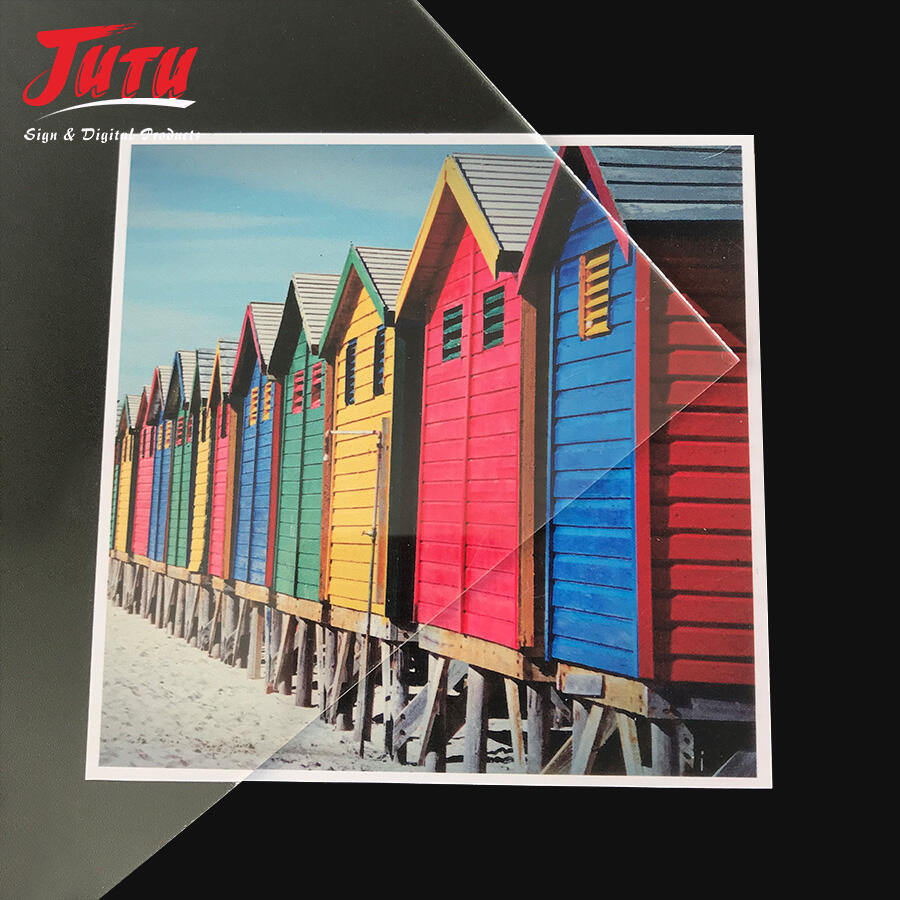

Seorang produsen lembaran akrilik besar merupakan entitas industri khusus yang berfokus pada produksi lembaran polimetil metakrilat (PMMA) berkualitas tinggi dalam dimensi luas dan ketebalan bervariasi. Produsen ini mengoperasikan fasilitas produksi canggih yang dilengkapi dengan teknologi ekstrusi, pengecoran, dan pengecoran kontinu untuk menciptakan lembaran akrilik yang melebihi batasan ukuran standar. Fungsi utama produsen lembaran akrilik besar adalah mengubah bahan akrilik mentah menjadi produk lembaran yang disesuaikan guna memenuhi berbagai kebutuhan industri, komersial, dan arsitektural. Proses manufaktur dimulai dari resin akrilik kelas premium, yang kemudian melalui prosedur pemanasan, pencetakan, dan pendinginan secara presisi untuk mencapai kejernihan optimal, kekuatan, serta stabilitas dimensi. Fasilitas produsen lembaran akrilik besar modern menggunakan lini produksi terkendali komputer yang menjamin toleransi ketebalan yang konsisten, hasil akhir permukaan unggul, dan sifat optik luar biasa di seluruh dimensi lembaran. Infrastruktur teknologi mencakup sistem kontrol kualitas mutakhir, peralatan pemotong otomatis, dan mesin penanganan khusus yang dirancang untuk mengelola panel akrilik berukuran besar tanpa mengorbankan integritas struktural. Produsen ini umumnya menyediakan lembaran dengan ketebalan mulai dari 2mm standar hingga kedalaman signifikan sebesar 100mm, dengan dimensi khusus yang melampaui format konvensional 3000mm x 2000mm. Kemampuan produksi mencakup berbagai jenis akrilik, termasuk akrilik cor untuk kejernihan optik superior, akrilik ekstrusi untuk solusi hemat biaya, serta formulasi khusus dengan ketahanan UV ditingkatkan, modifikasi tahan benturan, atau pencocokan warna tertentu. Aplikasi lembaran akrilik besar mencakup berbagai industri, seperti proyek kaca arsitektural, manufaktur otomotif, konstruksi kelautan, produksi rambu, desain furnitur, dan sistem tampilan khusus. Fleksibilitas produk-produk ini menjadikannya komponen penting dalam konstruksi akuarium, penghalang pelindung, perlengkapan pencahayaan, serta instalasi desain inovatif di mana keterbatasan kaca tradisional menjadi faktor penghambat bagi ekspresi kreatif.