11x17 produsen inti busa

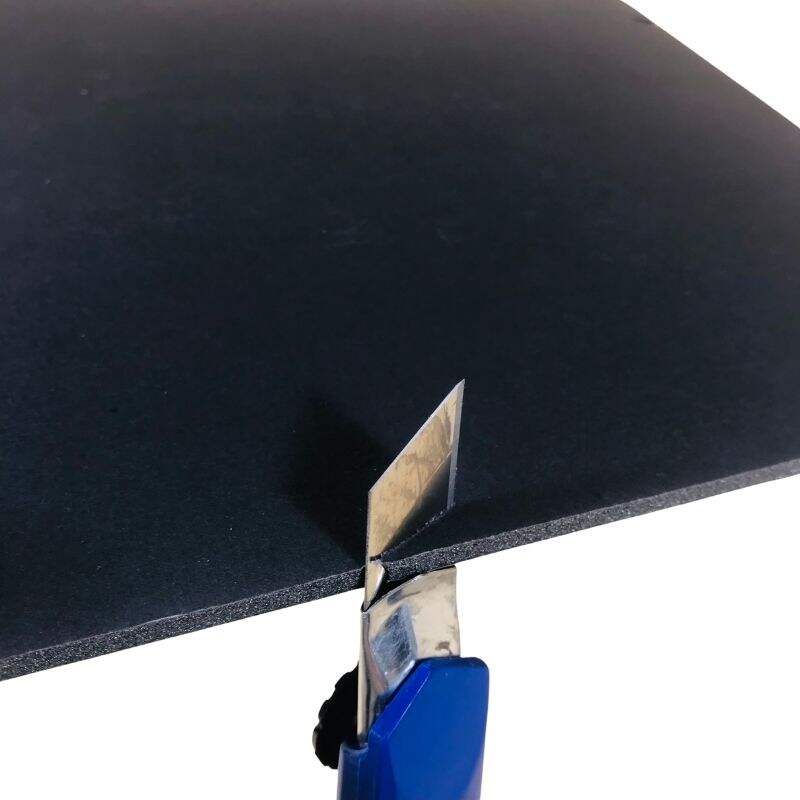

Seorang produsen foam core berukuran 11x17 mewakili fasilitas produksi khusus yang didedikasikan untuk membuat papan ringan dan kaku dengan ukuran 11 inci kali 17 inci. Para produsen ini menggunakan teknologi busa canggih untuk menghasilkan papan tampilan yang terdiri dari inti busa polistiren yang diapit oleh dua permukaan halus dari kertas atau plastik. Fungsi utama seorang produsen foam core 11x17 melibatkan proses pemotongan presisi, laminasi, dan kontrol kualitas yang menjamin dimensi yang konsisten serta kinerja produk yang unggul. Proses manufaktur dimulai dengan ekstrusi busa polistiren berkepadatan tinggi, yang membentuk struktur inti dan memberikan rasio kekuatan-terhadap-berat yang luar biasa. Sistem perekat canggih merekatkan permukaan luar ke inti busa, menciptakan integrasi sempurna yang mencegah terjadinya delaminasi dalam kondisi penggunaan normal. Fasilitas produsen foam core 11x17 modern menggunakan sistem pemotong yang dikendalikan komputer untuk menjamin ukuran yang akurat dan tepi yang rapi, menghilangkan potongan kasar yang sering terjadi pada metode pemotongan manual. Protokol jaminan kualitas dalam lingkungan manufaktur ini mencakup pengujian ketepatan dimensi, verifikasi kekuatan rekat, dan evaluasi kehalusan permukaan. Fitur teknologi dari seorang produsen foam core 11x17 profesional mencakup lingkungan produksi terkendali suhu, sistem penanganan material otomatis, serta alat pengukur digital yang menjaga spesifikasi produk tetap konsisten. Aplikasi produk dari produsen foam core 11x17 mencakup berbagai industri seperti studio desain grafis, firma arsitektur, institusi pendidikan, tampilan ritel, studio fotografi, dan lingkungan presentasi. Papan-papan ini digunakan sebagai permukaan tempelan untuk foto, karya seni, rambu, model arsitektur, proyek sekolah, tampilan pameran dagang, dan presentasi profesional. Fleksibilitas papan foam core menjadikannya sangat penting untuk instalasi sementara, tampilan permanen, dan aplikasi pelapis pelindung di mana pertimbangan berat sangat krusial.