pvc wall cladding panels

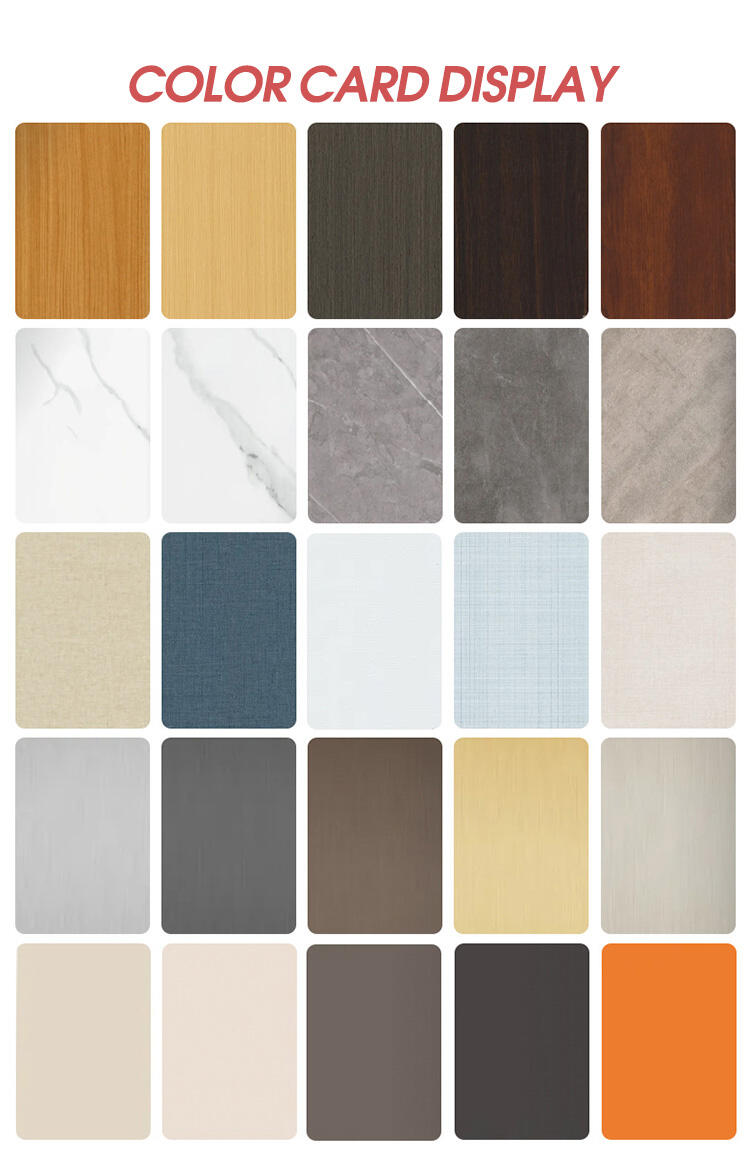

PVC wall cladding panels represent a revolutionary approach to interior and exterior wall covering solutions, combining durability, aesthetics, and functionality in a single product. These innovative panels are manufactured from high-quality polyvinyl chloride (PVC), a versatile thermoplastic polymer known for its exceptional resistance to environmental factors and long-lasting performance. The primary function of PVC wall cladding panels is to provide comprehensive wall protection while enhancing the visual appeal of residential, commercial, and industrial spaces. These panels serve as an effective barrier against moisture, dirt, scratches, and general wear, making them ideal for high-traffic areas and challenging environments. The technological features of PVC wall cladding panels include advanced UV stabilization, which prevents color fading and material degradation when exposed to sunlight. The panels incorporate interlocking mechanisms that ensure seamless installation and create watertight joints, preventing moisture infiltration. Many modern PVC wall cladding panels feature antimicrobial properties, inhibiting the growth of bacteria, mold, and mildew, which makes them particularly suitable for healthcare facilities, kitchens, and bathrooms. The surface texture of these panels can range from smooth finishes to embossed patterns that mimic natural materials like wood grain or stone textures. Applications for PVC wall cladding panels span across multiple sectors, including residential bathrooms, commercial kitchens, hospital corridors, educational institutions, retail spaces, and industrial facilities. In residential settings, homeowners appreciate how PVC wall cladding panels transform outdated spaces into modern, hygienic environments. Commercial applications benefit from the low maintenance requirements and easy cleaning properties of these panels. The panels are available in various dimensions, colors, and finishes, allowing architects and designers to create customized solutions that meet specific project requirements while maintaining structural integrity and aesthetic appeal.